3d Laser Engraving Printer: Revolutionizing Precision and Creativity

Laser engraving technology has significantly evolved over the years, transforming from a niche industrial process to a widely accessible creative tool. Among the various machines available, the 3d laser engraving printer stands out for its versatility, precision, and ability to bring intricate designs to life. This article delves into the technology, applications, specifications, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and project ideas for the 3d laser engraving printer.

Laser Engraving Technology and Applications

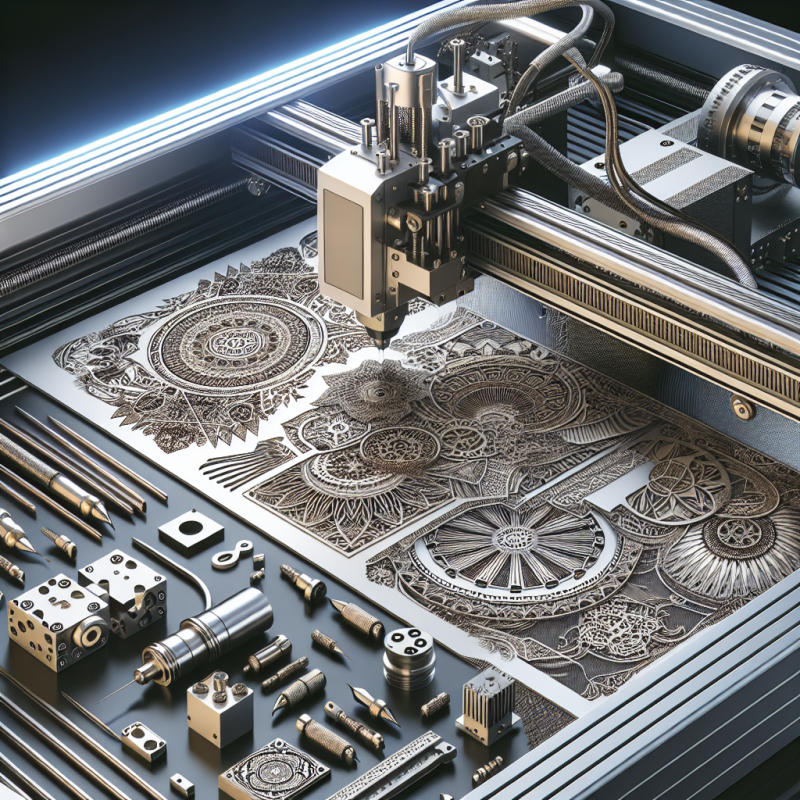

Laser engraving involves using a high-intensity laser beam to create precise and detailed designs on various materials. This non-contact process allows for intricate patterns, text, and images to be etched onto surfaces without causing damage to the surrounding areas. The 3d laser engraving printer leverages this technology to offer unparalleled precision and creativity.

Applications for laser engraving are vast and diverse. From personalized gifts and jewelry to industrial prototyping and branding, the technology is used across multiple industries. Artists and designers appreciate the ability to create intricate and personalized pieces, while businesses leverage laser engraving for branding, serialization, and product identification. The 3d laser engraving printer is particularly suited for small to medium-sized enterprises and hobbyists due to its compact size and ease of use.

Machine Specifications and Features

The 3d laser engraving printer boasts impressive specifications that cater to both professional and hobbyist needs. Here are some key features:

- High-Precision Laser Beam: The machine utilizes a high-power laser beam that can achieve precision down to 0.01mm, ensuring crisp and detailed engravings.

- Large Workspace: With a build volume of up to 300x300x400mm, the 3d laser engraving printer can accommodate a wide range of projects, from small jewelry pieces to larger decorative items.

- Multi-Material Compatibility: The machine supports a wide range of materials, including woods, metals, plastics, glass, and leather, making it versatile for different applications.

- Software Compatibility: The 3d laser engraving printer is compatible with popular design software such as Adobe Illustrator, CorelDRAW, and AutoCAD, allowing seamless integration with existing workflows.

- User-Friendly Interface: The intuitive control panel and software make it easy for beginners to get started while offering advanced features for professionals.

Material Compatibility

The 3d laser engraving printer excels in its ability to work with a variety of materials. Here’s a closer look at some of the materials it supports:

- Woods: Woods like basswood, plywood, and MDF are ideal for laser engraving due to their softness and ability to produce clean cuts.

- Metals: Engraving on metals such as stainless steel, brass, and aluminum requires a higher power setting but yields stunning results. The machine can handle thin sheets of metal with ease.

- Plastics: Materials like acrylic, polycarbonate, and ABS can be laser engraved to create vibrant and colorful designs.

- Glass: With the right technique, glass can be etched to create frosted designs that are both beautiful and functional.

- Leather: Leather items such as wallets, belts, and purses can be personalized with laser-etched designs, adding a touch of uniqueness and sophistication.

Safety Considerations

Safety is paramount when using any laser-based equipment. The 3d laser engraving printer comes with several safety features and considerations:

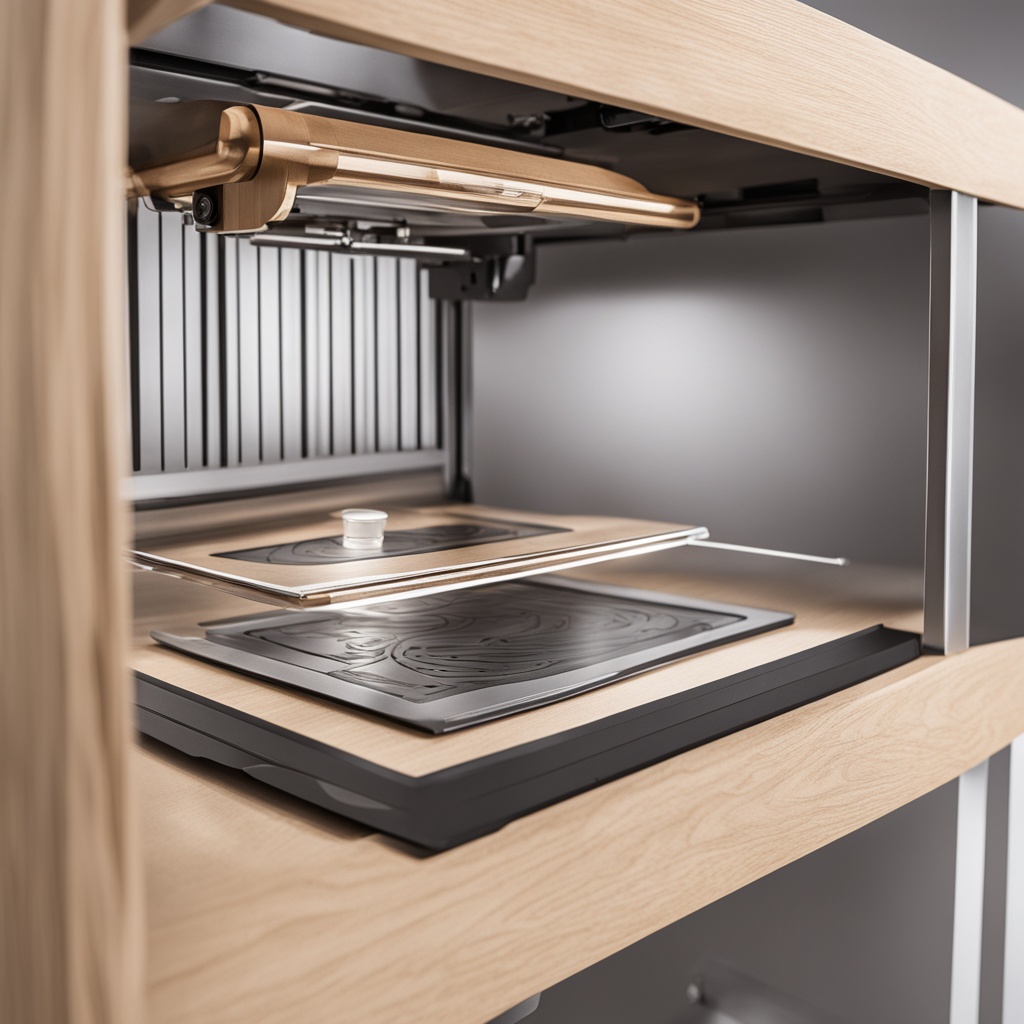

- Enclosed Workspace: The machine features an enclosed workspace to minimize laser exposure, protecting both the operator and the surrounding environment.

- Emergency Stop Button: An easily accessible emergency stop button allows for immediate shutdown in case of unexpected situations.

- Laser Safety Goggles: Always wear laser safety goggles when operating the machine to protect your eyes from laser radiation.

- Ventilation: Ensure proper ventilation in the workspace to avoid the accumulation of laser-generated fumes and particles.

- Training: Familiarize yourself with the machine’s operating instructions and safety protocols before use.

Industry Best Practices

To maximize the effectiveness and longevity of your 3d laser engraving printer, follow these industry best practices:

- Regular Maintenance: Perform regular maintenance checks, such as cleaning the lens and ensuring proper alignment of the laser beam.

- Optimize Settings: Experiment with different laser power settings, speeds, and focal distances to find the optimal settings for each material and project.

- Use Quality Materials: Invest in high-quality materials to ensure the best possible outcome and reduce the risk of damage to the machine.

- Backup Files: Always backup your design files to avoid data loss and ensure you can recreate your designs if needed.

- Stay Updated: Keep your software and machine firmware updated to benefit from the latest features and improvements.

Cost-Benefit Analysis

When considering the purchase of a 3d laser engraving printer, it’s important to weigh the costs against the benefits. Here’s a breakdown:

- Initial Investment: The upfront cost of the machine can be significant, but it’s a one-time expense. Compare prices from different manufacturers and consider your specific needs to find the best value.

- Operating Costs: Operating costs include materials, electricity, and maintenance. While these can add up, they are generally lower than traditional engraving methods.

- Revenue Generation: With the ability to create unique and personalized products, the 3d laser engraving printer can be a valuable asset for generating revenue through sales of customized items.

- Time Savings: Laser engraving is a faster and more efficient process than manual methods, allowing you to complete more projects in a shorter timeframe.

- Versatility: The versatility of the machine in terms of materials and applications makes it a versatile tool that can be used for a wide range of projects, further enhancing its cost-effectiveness.