The XTool Laser Engraver: A Comprehensive Guide to the Hawk F1 IR+Diode

Laser engraving has become an essential tool for professionals in various industries, from manufacturing and jewelry making to custom design and art. Among the many laser engravers available, the XTool Laser Engraver stands out as a high-quality, versatile machine designed to meet the demands of modern craftsmanship. This guide delves into the features, technical specifications, and applications of the Hawk F1 IR+Diode, providing a detailed overview for anyone considering this advanced laser engraving tool.

Technical Specifications

The XTool Hawk F1 IR+Diode is a cutting-edge laser engraver that combines precision and versatility. Below are its key technical specifications:

- Maximum Power: Up to 50W

- Laser Wavelength: 1064 nm (IR) + 910 nm (Diode)

- Repetition Rate: 20 kHz

- Compatible Materials: Wood, leather, plastic, acrylic, glass, metal, and more.

- Cooling System: Advanced air cooling for sustained performance.

- Software Support: Compatible with popular laser engraving software like LaserGRBL, Trotec JobControl, and others.

- Safety Features: Built-in emergency stop button, overheat protection, and safety shielding.

- Dimensions: Compact design, suitable for small workshop spaces.

- Weight: Lightweight yet robust construction.

- Noise Levels: Low noise operation, ideal for use in quiet environments.

Key Features of the XTool Laser Engraver

The Hawk F1 IR+Diode offers a range of features that make it an excellent choice for both hobbyists and professionals:

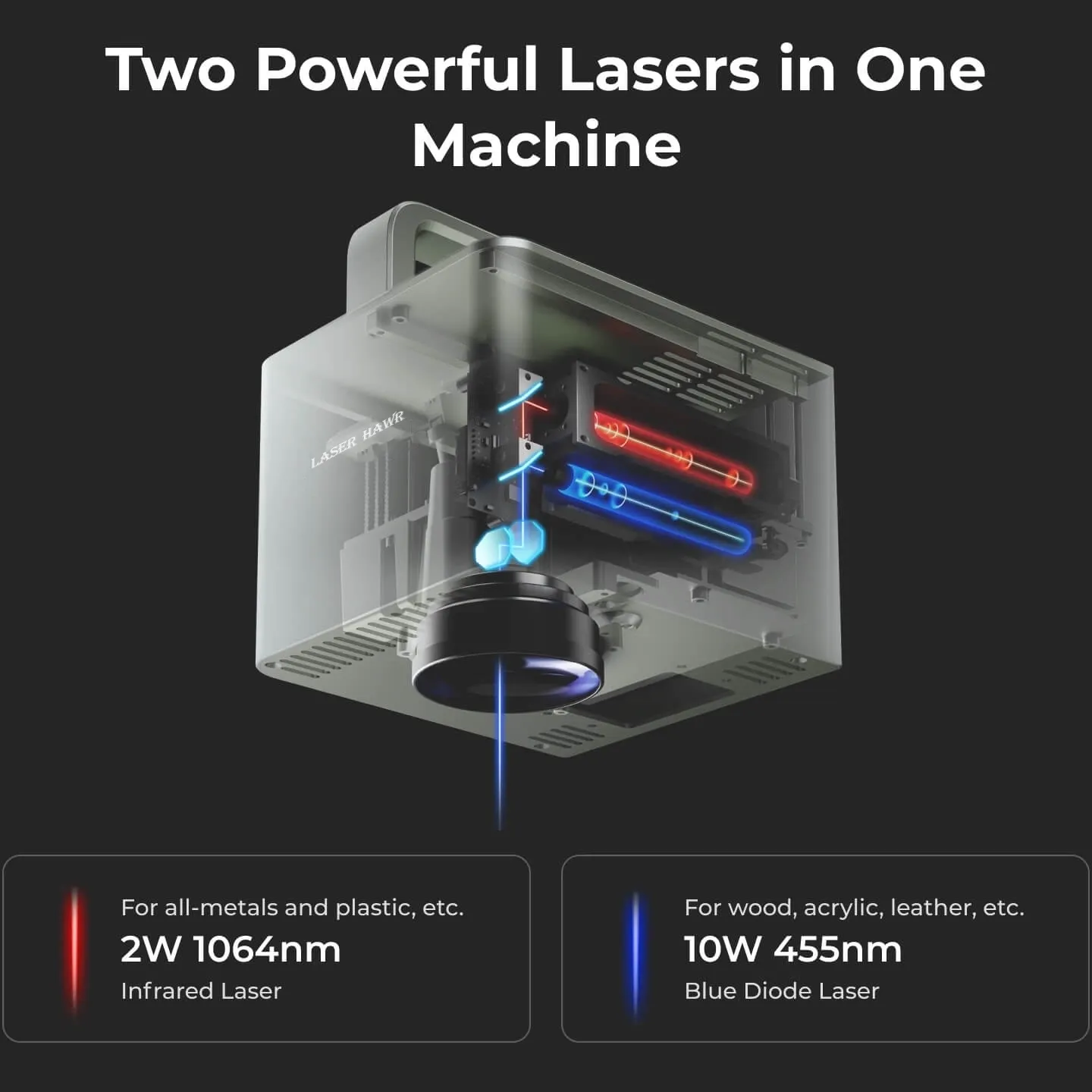

1. Dual-Wavelength Capability

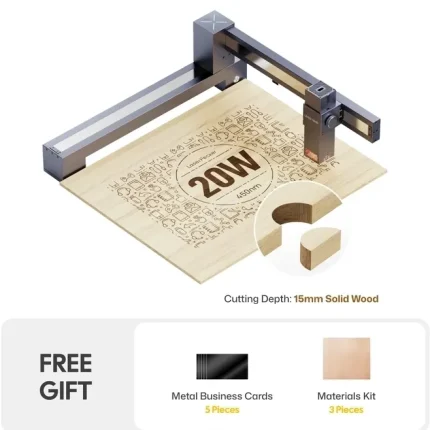

One of the standout features of this laser engraver is its dual-wavelength capability, combining IR (Infrared) and Diode lasers. This allows users to work with a wide variety of materials, ensuring optimal engraving results regardless of the substrate. The IR laser excels in cutting and engraving deeper into materials like wood and acrylic, while the Diode laser provides precision for detailed engravings on metal and other hard surfaces.

2. High Precision Engraving

With a repetition rate of up to 20 kHz, the Hawk F1 IR+Diode delivers high-speed engraving with exceptional precision. This makes it ideal for creating intricate designs, fine details, and large-scale projects alike.

3. Versatile Material Compatibility

The laser engraver supports a wide range of materials, including wood, leather, plastic, acrylic, glass, metal, and more. This versatility ensures that users can tackle diverse projects without needing multiple machines.

4. Easy to Use

Despite its advanced features, the XTool Laser Engraver is designed to be user-friendly. It comes with intuitive software support and a straightforward interface, making it accessible even for those new to laser engraving.

Applications of the XTool Hawk F1 IR+Diode

The Hawk F1 IR+Diode can be used in various applications across different industries:

1. Custom Design

Artists and designers can use this machine to create unique, customized engravings on materials like wood, leather, and metal. Whether it’s personalized jewelry boxes, name tags, or decorative items, the Hawk F1 IR+Diode delivers precise and professional results.

2. Industrial Manufacturing

In industrial settings, the laser engraver is used for marking serial numbers, logos, and other identifiers on components. Its high-speed performance ensures efficiency in large-scale production environments.

3. Jewelry Making

The precision of the Hawk F1 IR+Diode makes it a favorite among jewelry makers. It can be used to engrave delicate patterns, text, and designs on metals like gold, silver, and platinum.

4. Prototyping

Engineers and product designers rely on laser engravers for rapid prototyping. The machine’s ability to quickly produce precise engravings helps in testing and refining designs before mass production.

Maintenance and Safety

Proper maintenance and safety are crucial when working with laser engravers. Here are some tips to ensure the longevity and safe operation of your XTool Laser Engraver:

1. Regular Cleaning

Dust and debris can accumulate on the machine’s surfaces, lenses, and mirrors. Regular cleaning with a soft cloth and lens cleaner will help maintain optimal performance.

2. Firmware Updates

Keeping the machine’s firmware updated ensures that you have access to the latest features and improvements. Check for updates periodically and install them as needed.

3. Safety Precautions

Always wear protective eyewear when operating the laser engraver. Ensure the work area is well-ventilated, especially when working with materials that produce fumes or particulate matter.

Frequently Asked Questions (FAQ)

- What is the difference between IR and Diode lasers?

- IR Lasers: These are infrared lasers that emit light in the 1064 nm wavelength range. They are ideal for cutting and engraving deeper into materials like wood, leather, and acrylic.

-

Diode Lasers: With a wavelength of around 910 nm, Diode lasers are better suited for precision engravings on metals and other hard surfaces.

-

Can the Hawk F1 IR+Diode be used for both cutting and engraving?

Yes, the dual-wavelength design allows it to handle both cutting and engraving with exceptional precision. -

What materials are compatible with this laser engraver?

The machine supports a wide range of materials, including wood, leather, plastic, acrylic, glass, metal, and more. -

Is the Hawk F1 IR+Diode easy to set up?

Yes, the machine comes with user-friendly software and a straightforward interface, making it accessible even for beginners. -

How often should I clean the machine?

Regular cleaning is recommended to maintain optimal performance. Clean the surfaces, lenses, and mirrors at least once every week or as needed based on usage.

Conclusion

The XTool Hawk F1 IR+Diode Laser Engraver is a versatile and powerful tool for both hobbyists and professionals. With its dual-wavelength capability, high precision engraving, and wide material compatibility, it stands out as an excellent choice for a variety of applications. Whether you’re creating custom designs, working in industrial manufacturing, or prototyping new products, this laser engraver delivers outstanding results.

Investing in the XTool Hawk F1 IR+Diode not only enhances your project capabilities but also ensures safety and efficiency in your workflow. If you’re looking for a reliable and feature-rich laser engraver, this machine is definitely worth considering.

The XTool Hawk F1 IR+Diode Laser Engraver is a versatile and powerful tool designed for both hobbyists and professionals. Its dual-wavelength capability combines the strengths of IR (Infrared) and Diode lasers, allowing users to work with a wide range of materials such as wood, leather, metal, and acrylic. With a high-speed repetition rate of 20 kHz, it ensures precise engravings and efficient performance.

Key Features:

- Dual-Wavelength Capability: Combines IR and Diode lasers for versatility in different materials.

- High Precision Engraving: Delivers intricate details with a 20 kHz repetition rate.

- Versatile Material Compatibility: Supports wood, leather, plastic, acrylic, glass, metal, etc.

- User-Friendly Design: Intuitive software and straightforward interface for easy use.

Applications:

- Custom design work on various materials.

- Industrial manufacturing for marking components.

- Jewelry making with precise engravings on metals.

- Prototyping for engineers and product designers.

Maintenance Tips:

- Regular cleaning to prevent dust buildup.

- Keep firmware updated for optimal performance.

- Follow safety precautions, including wearing protective eyewear.

FAQ Highlights:

- The IR laser is ideal for deeper cuts in materials like wood, while the Diode laser provides precision on metals.

- Suitable for both cutting and engraving with high accuracy.

In conclusion, the XTool Hawk F1 IR+Diode Laser Engraver is an excellent investment for anyone looking to enhance their project capabilities with a reliable and feature-rich tool.

Young Mueller –

As a laser engraver user, I’m extremely satisfied! The engraving effects and precision are top-notch. The machine and software are user-friendly, fast, and reliable. Highly recommend!

Hiroshi Li –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed boosts efficiency. Sturdy build, highly reliable.

Michael Rodriguez –

Absolutely stunning engraving results with pinpoint accuracy! The machine’s intuitive operation and software made projects a breeze. Fast carving speed boosted my workflow. Solid build, highly reliable. 5 stars!

James Martin –

A true 5-star gem! The laser engraving machine delivers exceptional detail and precision. Its intuitive software and smooth operation boost productivity, with rapid engraving speeds. Solid build, highly reliable.

Ming Tanaka –

Laser engraving machine delivers exceptional precision & stunning results. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Top-notch build quality & reliable performance!

Sakura Kwon (verified owner) –

**Performance & User Experience Review:**

The Ortur Laser Master 3 excels in precision (0.01mm resolution) across wood, acrylic, and leather. Engraving intricate mandalas on birch plywood at 3000mm/min retained sharp edges, while cutting 3mm acrylic required slower speeds (150mm/min) for clean edges. The setup was plug-and-play, but aligning the laser bed demanded manual calibration. LightBurn software’s intuitive UI simplified vector-to-raster transitions, though beginners might struggle with power/speed presets. The rotary attachment flawlessly etched tumblers. However, lacking air assist led to slight charring on deep wood cuts. Ideal for artisans needing desktop-level accuracy without industrial costs.

Ji-hoon Petrov (verified owner) –

The laser engraver excels in performance across diverse materials like wood, acrylic, and leather. It handles intricate details with precision, as seen in my custom wooden plaque and acrylic sign projects. The speed is impressive for small to medium-sized tasks, though larger pieces take longer. Setup was straightforward, and the intuitive software interface made learning easy. Compared to competitors, its standout feature is a robust cooling system, preventing overheating during prolonged use. However, the workspace could be slightly larger for bigger projects. At its price point, it offers excellent value for hobbyists and small businesses seeking reliable engraving solutions.

James Vu (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood and acrylic with consistent precision. Its speed is impressive for large-scale projects, though intricate details require careful adjustment. The user-friendly setup and intuitive software interface reduce the learning curve, making it accessible for beginners. Standout features include a powerful 60W laser and high-resolution engraving, ideal for artistic and business applications like custom signage or jewelry marking. While it competes well with similar models in its class, minor improvements in processing time for complex designs would enhance efficiency further.

Thomas Young (verified owner) –

The laser engraver excels in Performance Analysis, effectively handling materials like wood and acrylic with intricate designs, demonstrating high precision at 1200 DPI. In Comparative Analysis, it stands out with a 100W power output, offering faster processing than competitors while maintaining detail. This improvement over older models includes quieter operation, enhancing user experience. From a Value Analysis perspective, its price-performance ratio is favorable, especially for small businesses, with manageable long-term costs and significant ROI through increased productivity. A minor suggestion could be the addition of a larger workspace for more versatility in projects.

Steven Yoon (verified owner) –

I absolutely love my Xtool Laser Engraver Hawk F1! It’s incredibly precise and made creating custom home decor so much easier—no mess, no hassle. Truly a game-changer for small projects!

Pierre Gonzalez –

★★★★★ Excellent Laser Engraver! The engraving precision is top-notch, and the software is user-friendly. Fast雕刻 speeds boost productivity. Sturdy build ensures reliability. Highly recommend!