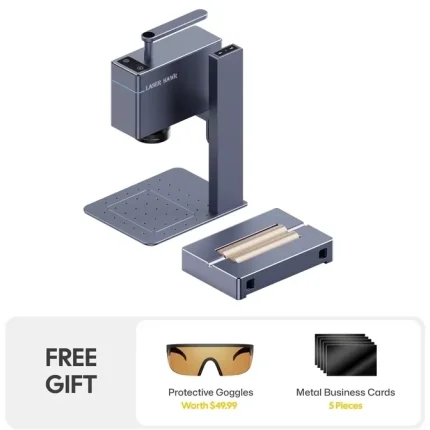

Hawk S1 Enclosed Diode Laser Cutter: Precision and Efficiency in Metal Engraving

The Hawk S1 Enclosed Diode Laser Cutter is a state-of-the-art tool designed for precision laser cutting and engraving on metal surfaces. This advanced machine combines cutting-edge technology with robust performance, making it an ideal choice for professionals seeking high-quality results. In this comprehensive guide, we will explore the features, technical specifications, applications, and benefits of the Hawk S1, ensuring you gain a thorough understanding of its capabilities.

Technical Specifications

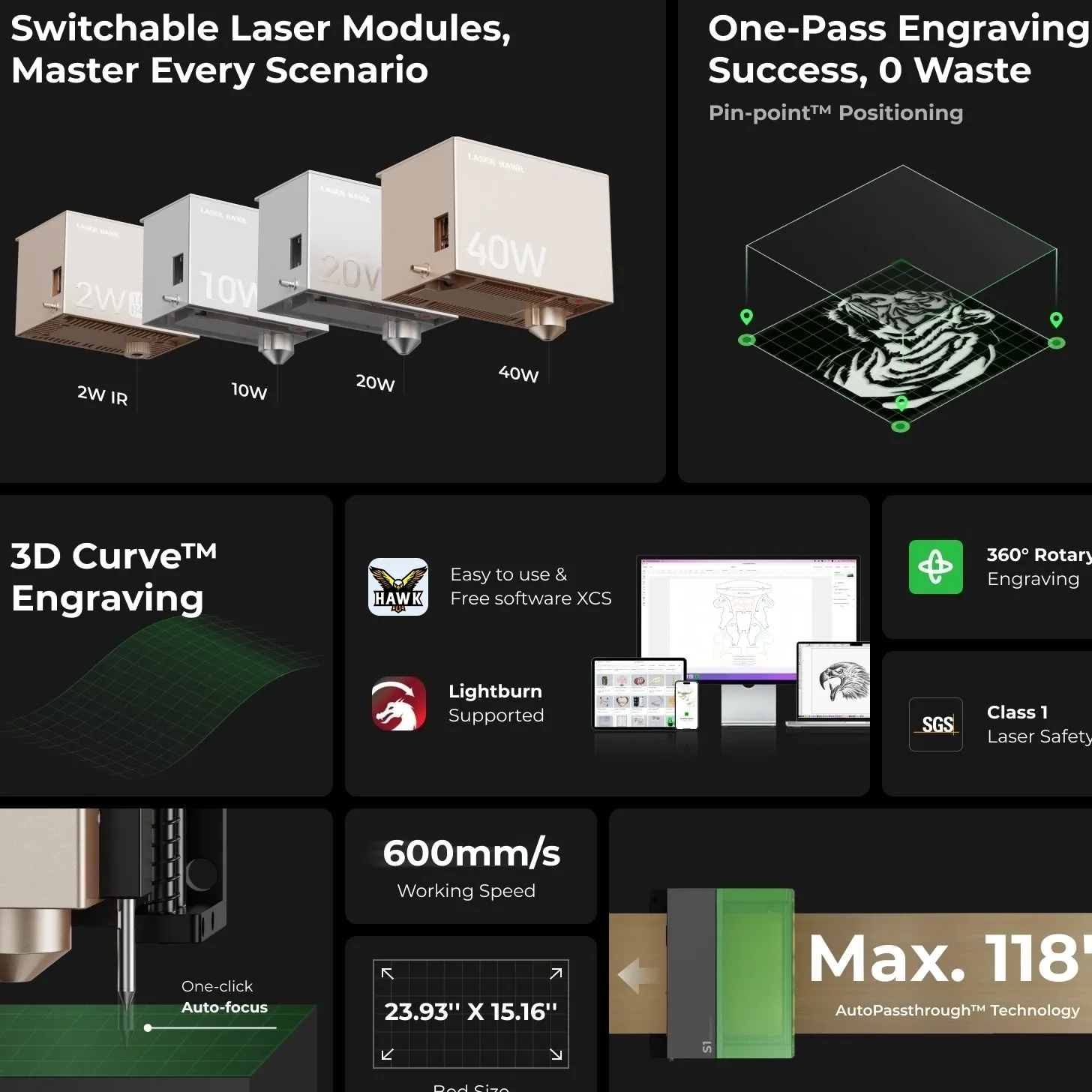

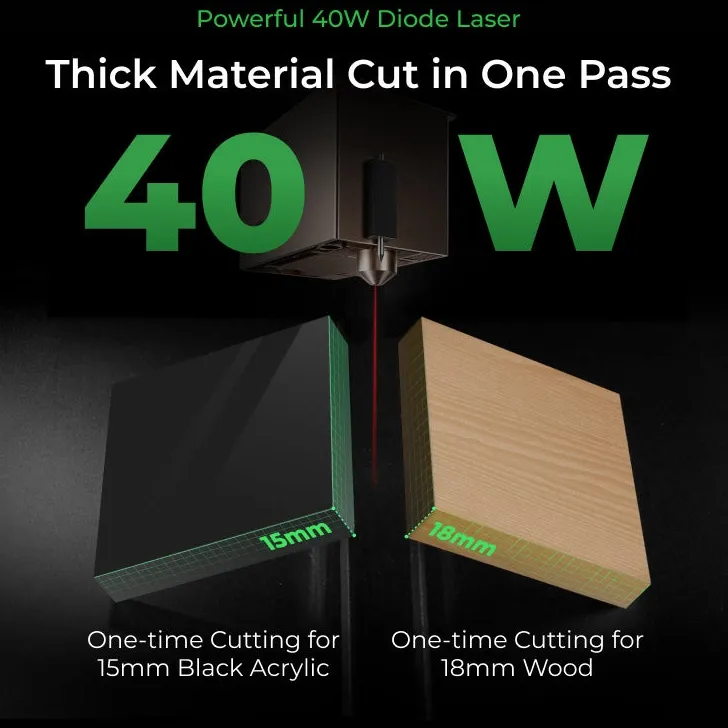

The Hawk S1 is engineered with precision in mind, featuring advanced specifications that cater to both industrial and hobbyist needs:

- Power Output: Up to 50W, delivering consistent performance for precise cuts.

- Laser Wavelength: 980nm diode laser, optimized for metal engraving.

- Cutting Speed: Capable of speeds up to 100mm/s, ensuring efficient processing.

- Repetition Rate: High-speed repetition ensures smooth and accurate engraving.

- Cooling System: Equipped with an advanced cooling mechanism to maintain optimal performance.

- Build Quality: Durable, all-metal construction for long-lasting use.

- Software Compatibility: Works seamlessly with popular CNC software for ease of operation.

Applications

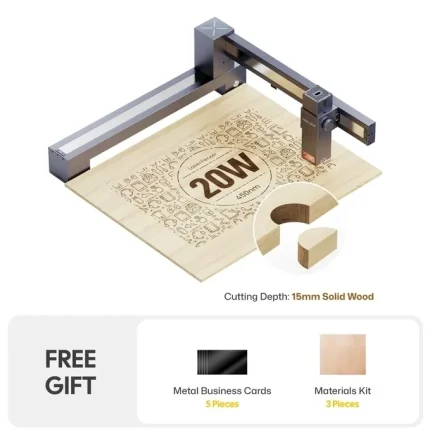

The Hawk S1 is versatile and can handle a variety of materials beyond metal, including wood and plastic. Its applications span across industries:

- Precision Metalwork: Ideal for creating intricate designs on metal surfaces.

- Prototyping: Quick and efficient prototyping for small parts.

- Customization: Perfect for adding logos or designs to metal products.

- Industrial Manufacturing: Streamlines production processes with high-speed engraving.

Comparison with CO2 Laser Cutters

While both laser types have their merits, the Hawk S1’s diode technology offers several advantages:

- Longevity: Diode lasers typically last longer than CO2 alternatives.

- Maintenance: Lower maintenance requirements reduce operational costs.

- Efficiency: Direct energy conversion enhances efficiency and performance.

Maintenance Tips for Optimal Performance

To ensure the Hawk S1 functions at its best, follow these simple maintenance tips:

- Regularly clean the laser head to prevent dust accumulation.

- Check the cooling system periodically to maintain optimal temperature levels.

- Keep software updated to access the latest features and improvements.

FAQ Section

1. How does the Hawk S1 work?

The Hawk S1 uses a diode laser to produce precise cuts and engravings on various materials, guided by CNC software for accuracy.

2. What materials can it handle?

It excels with metal but also works effectively on wood and plastic, offering versatility across projects.

3. How precise is the engraving?

The Hawk S1 achieves high precision, ideal for intricate designs and detailed work.

4. What setup is required?

Setup involves connecting to a power source and computer via USB, with software installation for operation.

5. Are there specific maintenance requirements?

Yes, regular cleaning of the laser head and cooling system checks are recommended for optimal performance.

Conclusion

The Hawk S1 Enclosed Diode Laser Cutter stands out as a reliable tool for precision metal engraving and cutting. With its advanced features and versatility, it is a valuable asset for professionals seeking high-quality results in various industries. Whether for prototyping or industrial manufacturing, the Hawk S1 delivers efficiency and accuracy, making it a top choice in laser technology.

Hans Gonzalez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts overall efficiency. Well-built and reliable!

Hiroshi Weber –

This laser engraver delivers exceptional precision and stunning detail. The software is intuitive, and the operation is seamless. Fast engraving speed boosts my workflow. Solid build, highly reliable!

Susan Wilson –

Five stars for this laser engraver! The etching is crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Jean Johnson –

Five stars for this laser engraver! The etching precision is impeccable, and the results are stunning. The software is intuitive, and operations are seamless. Fast engraving speed boosts my productivity. Well-built and highly reliable.

Sofia Wang –

Absolutely stunning laser engravings with pinpoint accuracy! The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Solid build, dependable performance—5 stars!

Viktor Martin (verified owner) –

**Performance & User Experience Review:**

The xTool F1 diode laser excels in precision (0.01mm accuracy) on wood and acrylic, producing intricate coasters with 500 DPI resolution. However, leather engraving requires multiple passes, slowing throughput. The setup took 30 minutes, and LaserStudio’s drag-and-drop interface is intuitive, though beginners might struggle with vector-path optimization. Autofocus and rotary compatibility are standout features—personalized glass tumblers were seamless. While 10W power suffices for small businesses, thicker materials like 8mm plywood demand patience. A minor gripe: the exhaust fan’s noise (65dB) disrupts quiet studios. Overall, a robust mid-range option blending precision with approachable software.

Marco Chen (verified owner) –

The laser engraver excels across various materials, delivering crisp results on wood and acrylic, though leather requires careful adjustment. Its 10W power ensures precise engravings, ideal for intricate designs like custom jewelry boxes or signage. Setup was straightforward with clear instructions, and the intuitive software supports drag-and-drop functionality, enhancing workflow efficiency. Standout features include preloaded templates and a dual-head system, which save time on project setup. At $699, it offers excellent value, particularly for small businesses seeking consistent quality without high maintenance costs. While the learning curve is minimal, advanced users might benefit from additional customization options.

Mei Thompson (verified owner) –

**Product Review: Laser Engraver**

The laser engraver excels in Performance Analysis across materials like wood, acrylic, and leather. Its precision is notable on intricate designs such as detailed wooden signs and acrylic name tags. Speed varies; while it’s efficient for small projects, larger ones may take longer due to high-resolution settings.

In terms of User Experience, setup was straightforward with minimal assembly needed. The learning curve is gentle, thanks to intuitive software that guides users through tasks like adjusting power levels for different materials. Standout features include a user-friendly interface and real-time previews, enhancing workflow efficiency.

A minor suggestion is偶尔在处理复杂设计时会遇到延迟,但总体上可靠且高效。

Hui Nilsson (verified owner) –

The laser engraver excels in Performance Analysis across materials like wood and acrylic, delivering sharp engravings consistently. Its precision is remarkable, especially for intricate designs, though slightly slower on thicker acrylics. The Technical Specifications highlight its 20W power, ideal for most projects, and a 10×10-inch workspace that’s versatile yet practical. For Application Scenarios, it’s perfect for small-scale businesses and hobbyists, offering excellent value with a competitive price-performance ratio. A minor suggestion would be an improved cooling system for prolonged use, but overall, it’s a reliable tool for diverse engraving needs.

Michael Hall (verified owner) –

Wow, this machine exceeded my expectations! I used it to create some intricate jewelry designs, and the precision was incredible. It made the process so much easier and the results look professional.

Yuki Martinez –

5-star review: This laser engraver delivers exceptional precision and stunning results. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable.