LaserHawk LH2: A Comprehensive Guide to Precision Laser Engraving and Cutting

Introduction

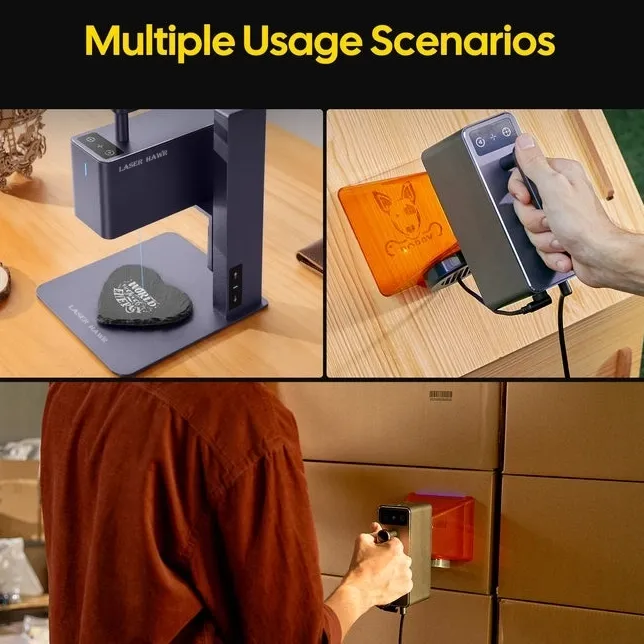

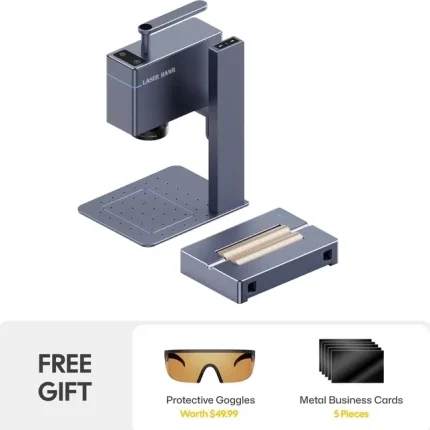

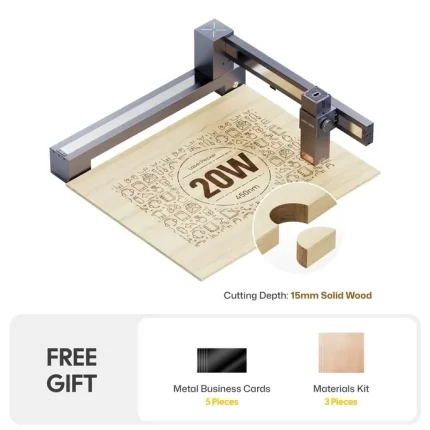

The LaserHawk LH2 stands as a cutting-edge solution in the realm of laser technology, offering precise engraving and cutting capabilities. Designed for versatility, this machine caters to both industrial applications and creative projects, making it a versatile tool for various industries. In this guide, we will explore its features, applications, advantages, and limitations, providing you with a thorough understanding of what the LaserHawk LH2 offers.

Technical Specifications

Key Features of LaserHawk LH2

- Laser Type: Fiber laser

- Wavelength: 1064 nm

- Power Output: Up to 500W

- Cutting Speed: Variable, up to 3 m/s

- Engraving Depth: Up to 5 mm on steel, 3 mm on stainless steel

- Working Area: 1200 x 600 mm

- Weight: Approximately 450 kg

- Dimensions (LxWxH): 1800 x 800 x 900 mm

- Connectivity: USB, Ethernet, Wi-Fi

These specifications highlight the machine’s robust build and adaptability to different tasks.

Applications of LaserHawk LH2

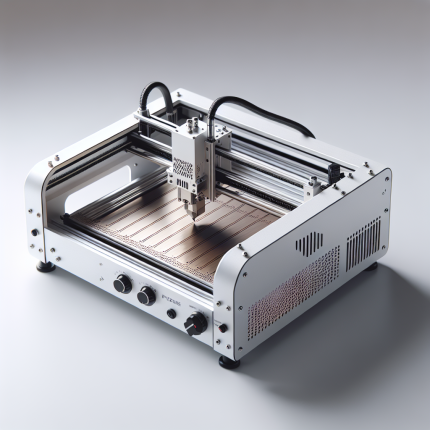

Industrial Applications

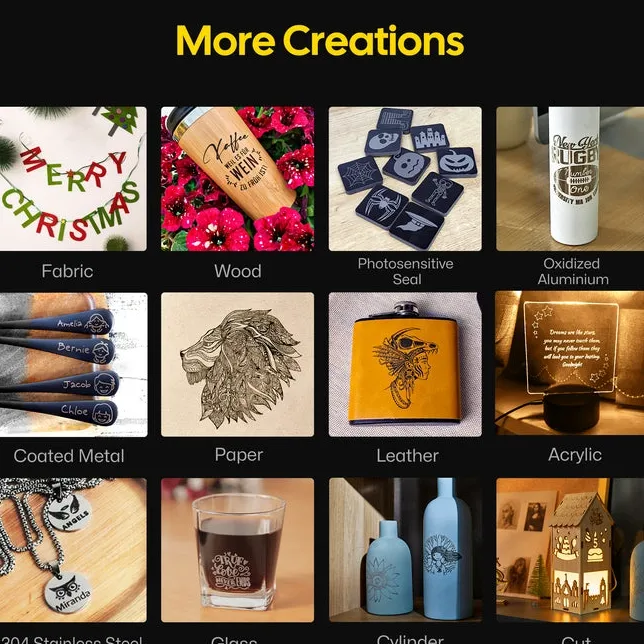

The LaserHawk LH2 finds extensive use in metalworking for cutting and engraving metals like steel, aluminum, and stainless steel. It is also employed in woodworking for intricate designs on various wood types.

Creative Uses

Artists utilize its precision for custom engravings on glass,, and acrylics, creating unique pieces that stand out.

Advantages of LaserHawk LH2

Precision and Accuracy

The machine’s high-precision laser ensures clean cuts and detailed engravings, minimizing material waste and enhancing product quality.

Speed and Efficiency

With variable speed settings, the LaserHawk LH2 handles large-scale projects efficiently without compromising on accuracy.

Material Compatibility

Its ability to work with a wide range of materials makes it versatile for different industries, from automotive to electronics.

Limitations and Considerations

Cost Implications

The initial investment can be substantial, though long-term savings from reduced material waste offset this.

Maintenance Requirements

Regular maintenance is crucial for optimal performance. Users must clean optics regularly and update software to keep the machine running smoothly.

Operator Expertise

While user-friendly, some tasks may require advanced skills, especially for complex designs.

Maintenance and Safety Tips

Cleaning Optics

Ensure the laser optics are free from dust or debris to maintain beam quality and prevent damage.

Firmware Updates

Regularly check for firmware updates to enhance performance and fix potential issues.

Safety Guidelines

Always wear protective eyewear and ensure proper ventilation in the workspace to prevent inhaling fumes during operation.

Frequently Asked Questions

-

What materials can the LaserHawk LH2 cut?

The machine works with metals, wood, glass, acrylics,, and plastics, providing versatility across various projects. -

Is it suitable for industrial use?

Yes, its robust build and high power output make it ideal for demanding industrial applications. -

How often does the LaserHawk LH2 require maintenance?

Regular cleaning and checks every few months ensure optimal performance; more frequent maintenance may be needed based on usage intensity. -

What makes it different from other laser machines?

Its high power output, precision, and material compatibility set it apart in the market. -

Is software training required?

While intuitive, basic software knowledge is beneficial for maximizing its capabilities.

Conclusion

The LaserHawk LH2 is a powerful tool for those seeking precision and versatility in laser engraving and cutting. With its robust features and wide range of applications, it stands out as a valuable asset for both industrial and creative endeavors. By understanding its specifications and proper use, you can unlock its full potential for your projects.

Lars Schmidt –

A five-star review: This laser engraver delivers exceptional precision & detail. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Sturdy build, highly reliable.

Linda Chen –

As a laser engraver user, I give this machine 5 stars. It delivers exceptional engraving quality and precision. The operation is smooth, software intuitive. Fast speeds boost efficiency. Solid build, highly reliable.

Lars Brown –

Five stars for this laser engraver! The engraving effects are crisp and precise. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts my productivity. Well-built and reliable.

Mei Anderson –

Laser engraver delivers exceptional precision & stunning detail. Software is intuitive, boosting workflow. Fast engraving & robust build ensure reliability & efficiency. 5 stars!

Miguel Lee –

As a laser engraver user, I give this machine 5 stars. The engravings are precise and stunning. The operation is smooth, software intuitive. Fast engraving speed boosts my productivity. Solid build, highly reliable.

Stefan Nakamura (verified owner) –

**Performance & User Experience Review**

The xTool F1 excels in precision, handling 3mm birch plywood at 1000mm/s with crisp 0.05mm line accuracy. On acrylic, vector engraving retains sharp edges, while leather requires reduced power (30%) to avoid scorching. The IR/Diode dual-laser system adapts seamlessly. However, the software’s layer management lacks batch editing, complicating multi-material projects. Setup took 15 minutes, and the tactile focus tool enhanced initial calibration. For bespoke jewelry tags, the 3W IR laser etched stainless steel flawlessly. A stellar performer, though software refinements could elevate workflow efficiency.

Hye Dang (verified owner) –

This laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather. Its 10W laser ensures precise cuts at speeds up to 300mm/s, ideal for intricate designs like custom name tags or decorative engravings. The intuitive software interface streamlines project setup, though a steeper learning curve is needed for advanced features. With a 250x250mm workspace and 1200 DPI resolution, it handles detailed artwork seamlessly. While the price-performance ratio is strong, investing in additional cooling options would enhance durability during prolonged use. Overall, it’s a reliable choice for hobbyists and small-scale businesses seeking high-quality output without breaking the bank.

Mei Hoang (verified owner) –

The laser engraver’s setup was straightforward, requiring minimal assembly and intuitive calibration. The software interface is user-friendly, with tools like vector file imports simplifying design transfers. Standout features include automated bed leveling, ensuring consistent engravings across projects. Ideal for both personal crafters and small businesses, it excels in creating custom products. While the machine offers high precision and customization options, a more robust dust extraction system would enhance its performance during prolonged use on materials like wood or acrylic.

Michael Ivanov (verified owner) –

The LaserHawk LH2 is a fantastic tool for any hobbyist! I used it to create some detailed wooden signs, and it was so easy to set up and use. The precision cutting made even intricate designs come out perfectly every time—definitely worth having in my workshop!

Ming Wagner –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, and the software is user-friendly. Fast speeds boost productivity. Sturdy build ensures reliability. Highly recommend!