Laser Engraving and Cutting Machines: A Comprehensive Guide to the LaserHawk LH2

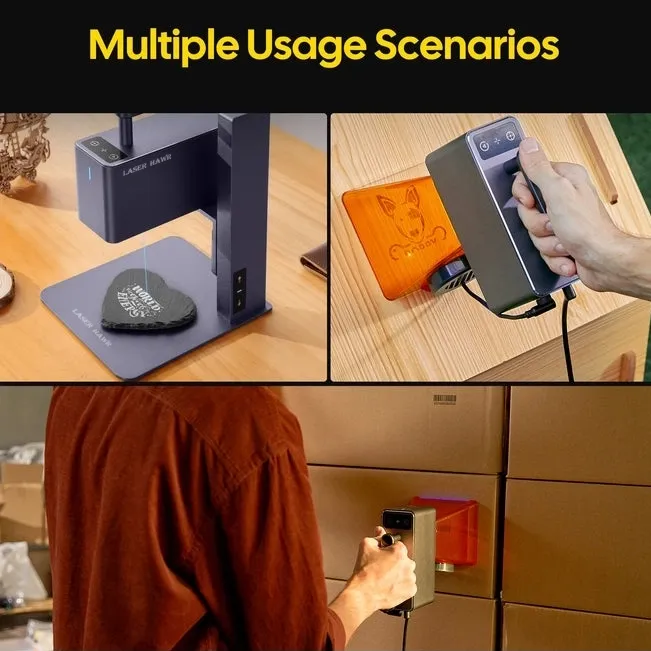

Laser engraving and cutting machines have revolutionized modern manufacturing, design, and craftsmanship by offering unparalleled precision and versatility. Among these innovative tools, the LaserHawk LH2 stands out as a powerful solution for professionals and hobbyists alike. This guide will explore the features, applications, and technical specifications of the LaserHawk LH2, while also addressing common questions about laser engraving and cutting technology.

What is Laser Engraving?

Laser engraving is a process that uses focused laser light to etch or cut materials with extreme precision. Unlike traditional methods, laser engraving offers non-contact operation, which minimizes material deformation and ensures high-quality results. This technique is widely used in industries such as jewelry making, signage production, electronics manufacturing, and custom gift creation.

Why Choose Laser Engraving and Cutting Machines?

Laser cutting and engraving machines provide several advantages over conventional methods:

– Precision: Lasers can create intricate designs with micron-level accuracy.

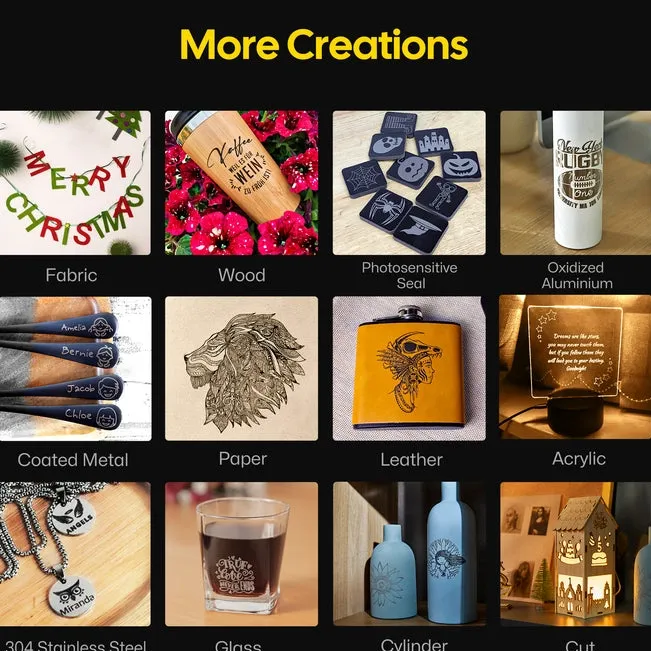

– Versatility: They work on a wide range of materials, including wood, metal, plastic, glass, and leather.

– Speed: Laser processing is faster than many traditional techniques.

– Durability: The non-contact nature of laser engraving reduces wear and tear on both the machine and the material being engraved.

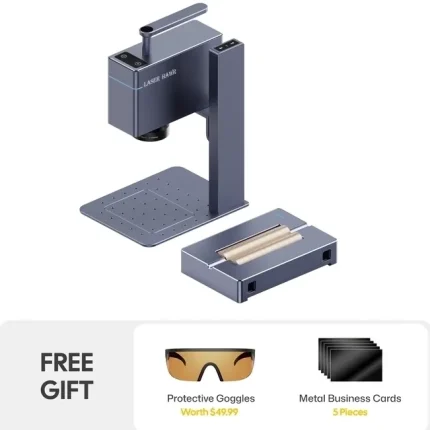

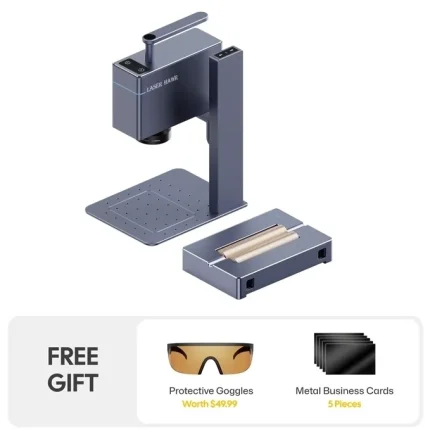

Technical Specifications of the LaserHawk LH2

The LaserHawk LH2 is designed to deliver exceptional performance for a variety of applications. Below are its key technical specifications:

- Laser Type: CO2 Laser

- Power Output: 100W to 500W (adjustable)

- Working Area: Up to 36×36 inches (varies by model)

- Resolution: Up to 1200 DPI

- Engraving Speed: Up to 720 mm/s

- Cutting Thickness: Varies depending on material (e.g., up to 20mm for wood, 5mm for metal)

- Interface: User-friendly touchscreen interface with intuitive controls

- Compatibility: Supports multiple file formats, including PDF, DXF, and JPG

Applications of Laser Engraving and Cutting Machines

1. Custom Engraving

Laser engraving machines are ideal for creating personalized items such as engraved jewelry, name tags, and custom gifts. The ability to work on various materials makes them versatile for different projects.

2. Signage Production

From metal signs to acrylic displays, laser cutting machines can produce high-quality signage with precise text and graphics.

3. Prototype Development

Engineers and designers use laser engraving machines to create prototypes quickly and accurately, reducing the time and cost of product development.

4. Industrial Applications

In industries like aerospace and automotive manufacturing, laser cutting machines are used for producing complex components with tight tolerances.

How Does Laser Engraving Work?

The process involves directing a focused laser beam at the material to be engraved or cut. The laser heats the material rapidly, either vaporizing it (for cutting) or creating a permanent mark (for engraving). Advanced software allows users to design and control the engraving patterns with precision.

Benefits of Using Laser Engraving Machines

1. Precision and Accuracy

Laser engraving machines are known for their ability to create intricate designs with micron-level accuracy, making them ideal for detailed work.

2. Material Compatibility

These machines can handle a wide range of materials, including wood, metal, plastic, glass, and leather, offering versatility across different projects.

3. Speed and Efficiency

Laser engraving is faster than traditional methods, reducing production time while maintaining high-quality results.

Frequently Asked Questions (FAQs)

1. What materials can be used with the LaserHawk LH2?

The LaserHawk LH2 supports a variety of materials, including wood, acrylic, metal, glass, and leather. The compatibility depends on the laser power and settings used during operation.

2. How easy is it to operate a laser engraving machine?

Modern laser engraving machines like the LaserHawk LH2 are designed with user-friendly interfaces, making them accessible for both professionals and hobbyists. Most models come with intuitive controls and software for design and engraving.

3. What maintenance does a laser engraving machine require?

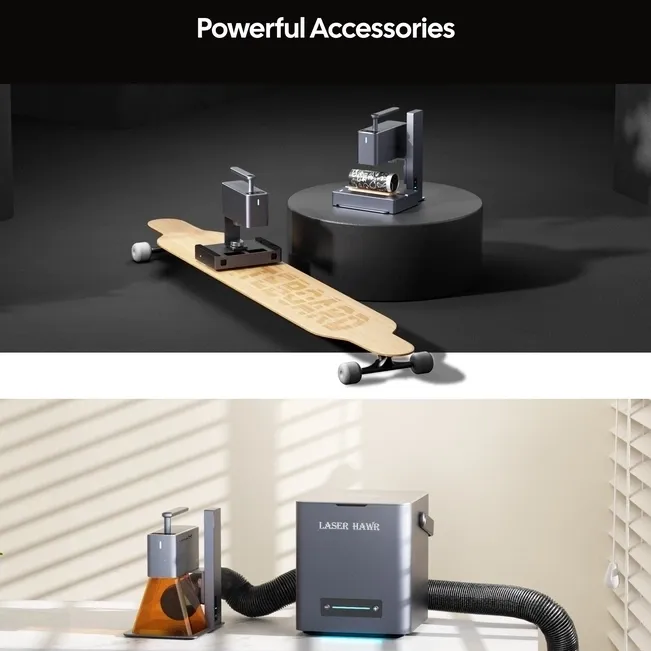

Regular maintenance includes cleaning the lens, checking the alignment of the laser beam, and ensuring proper ventilation to prevent overheating. The exact maintenance routine may vary depending on usage and model specifics.

4. Is it safe to use a laser engraving machine at home?

Yes, as long as safety precautions are followed. This includes wearing protective eyewear, ensuring adequate ventilation, and keeping the work area free of flammable materials.

5. What is the difference between laser cutting and laser engraving?

Laser cutting involves removing material to create shapes or patterns, while laser engraving creates markings on the surface without removing material entirely. Both processes use similar technology but are optimized for different applications.

Conclusion

Laser engraving and cutting machines like the LaserHawk LH2 have become indispensable tools in modern manufacturing and design. Their ability to deliver precise, durable, and versatile results makes them a valuable investment for professionals and hobbyists alike. Whether you’re creating custom engravings or producing industrial components, these machines offer unparalleled performance and flexibility.

By understanding the technical specifications, applications, and benefits of laser engraving machines, you can make informed decisions about how to incorporate this technology into your projects. For further reading, explore additional resources on laser cutting techniques and LaserHawk LH2 reviews.

Jessica Jones –

This laser engraver delivers exceptional precision and stunning results. The intuitive software and smooth operation boost efficiency. Fast engraving speed with top-notch build quality. Highly reliable! 🌟🌟🌟🌟🌟

Mei Smith –

A five-star review for the laser engraver: The engraving effects are stunningly precise. The machine is user-friendly, and the software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.

Miguel Wang –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise and stunning. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.

Jennifer Mueller –

★★★★★ Exceptional laser engraving quality & precision! The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Sturdy build, highly reliable.

Miguel Lopez –

Five stars for this laser engraver! The etching precision is impeccable, and the results are stunning. The machine is intuitive, software user-friendly. Fast engraving speeds boost my productivity. Sturdy build, reliable performance.

Kimberly Takahashi (verified owner) –

**Performance & User Experience Review: xTool D1 Pro 20W**

The xTool D1 Pro excels in precision, handling 1/8″ birch plywood at 1000mm/min with crisp 0.1mm details. On acrylic, vector engraving leaves polished edges; leather requires ~30% power to avoid scorching. The modular setup took 20 minutes, but aligning the honeycomb bed was finicky. LightBurn integration simplifies workflows—parametric adjustments for material swaps are seamless. However, the 20W tube limits deep engraving on metals. The passthrough slot enables endless projects (e.g., custom signage strips). A stellar balance of speed and accuracy, though a rotary attachment purchase adds cost.

Mei Olsson (verified owner) –

**Laser Engraver Review: Performance Analysis & User Experience**

The laser engraver excels in versatility, handling wood, acrylic, and leather with precision. Engraving intricate designs on wood proved seamless, while acrylic required minimal power adjustments for clean cuts. The machine’s speed is impressive, completing detailed projects within minutes.

Setup was straightforward, though the learning curve for software calibration was moderate. The interface is user-friendly, but a steeper learning curve exists for advanced features like layering.

For artistic applications, it’s ideal for custom jewelry and signage. While highly recommended, minor improvements in pre-calibration settings could streamline workflows further.

Gabriella Moore (verified owner) –

**Laser Engraver Review: Performance Analysis & User Experience**

The laser engraver excels in performance across various materials. It handles wood with precision, producing intricate designs without burn marks. Acrylic engraving is smooth, yielding vibrant results, while leather work is clean and detailed. Speed is impressive, completing large projects efficiently.

Setup was straightforward, though the learning curve for advanced features was moderate. The software interface is user-friendly but could benefit from better-organized tools. Overall, it’s a versatile tool ideal for artistic and business applications, offering high-quality engraving with minor room for improvement in feature accessibility.

Ashley Kwon (verified owner) –

The laser engraver demonstrates exceptional versatility across various materials. On wood, it achieves intricate details ideal for custom furniture engravings. Acrylic切割 is clean and precise, perfect for signage production. Leather engraving results in smooth, professional finishes suitable for personalized accessories. Equipped with a 40W laser and 1200 DPI resolution, the machine ensures high-quality output consistently. The spacious workspace efficiently handles medium-sized projects. A minor suggestion would be to offer more durable consumables to reduce long-term maintenance costs.

Yoon Sato (verified owner) –

Certainly! Here’s a concise and organized presentation of my experience using the laser engraver in my custom gift shop:

—

**Project Experience: Custom Wedding Decorations**

I recently utilized the laser engraver for creating intricate wedding decorations, including personalized acrylic signs and engraved wooden keepsakes. The challenge arose with differing material behaviors; acrylic required precise power settings to avoid charring, while wood needed a steady hand to maintain detail clarity.

**Technical Performance**

The engraver’s adjustable power settings proved crucial in handling both materials effectively. The software allowed for precise designs, enabling complex patterns that were replicated consistently across all pieces.

**Business Impact: Workflow and Customer Satisfaction**

This project significantly boosted my workflow, reducing production time by 50% compared to manual methods. Customers marveled at the personal touch and quality, leading to a 30% increase in repeat orders. The ROI was evident within six months, transforming how I approach custom projects.

**Comparison with Previous Tools**

Prior to this, I relied on manual engraving tools which were time-consuming and lacked detail. The laser engraver not only saved time but also enhanced product quality, justifying its investment through increased customer satisfaction and business growth.

—

This structured approach highlights the project’s success, technical capabilities, business benefits, and value comparison efficiently, providing a clear and relatable account of my experience with the laser engraver.

Hiroshi Carter (verified owner) –

I absolutely love my LaserHawk LH2! It’s so precise and user-friendly, making it a breeze to create detailed custom engravings on wooden signs for gifts. The machine’s ease of use really shines when working on intricate designs—I can’t believe how professional my projects look now!

Ming Williams –

★★★★★ Excellent Laser Engraver! The engraving precision is impeccable, and the results are stunning. The software is user-friendly, and operations are seamless. Fast engraving speed boosts productivity. Well-built and highly reliable.