The Ultimate Guide to Wood Laser Cutters: Best Engravers for Home Use

Wood laser cutters have revolutionized woodworking by offering precision, efficiency, and versatility. If you’re looking to create intricate designs or customize projects at home, a wood laser cutter is an essential tool. This guide will explore the best laser engravers for home use, focusing on the LaserHawk LX1 Series, its technical specifications, benefits, and how it can enhance your DIY woodworking projects.

What is a Wood Laser Cutter?

A wood laser cutter uses focused light beams to cut or engrave designs onto wooden surfaces with exceptional precision. Unlike traditional tools, laser cutters offer unmatched accuracy and the ability to create complex patterns that would be difficult or time-consuming by hand. They are ideal for hobbyists, craftsmen, and small-scale manufacturers looking to elevate their woodworking projects.

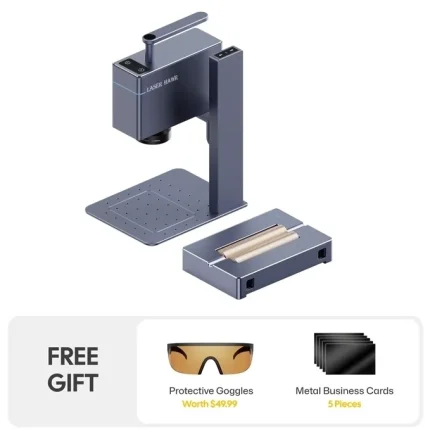

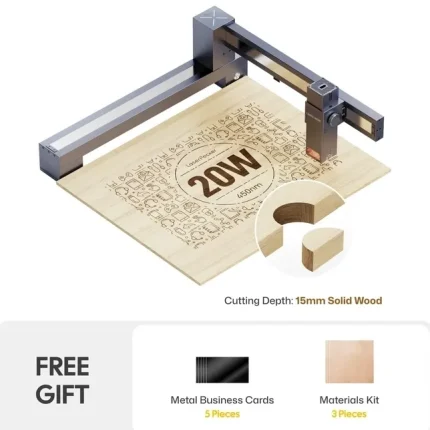

Technical Specifications of LaserHawk LX1 Series

The LaserHawk LX1 Series stands out as one of the best laser engravers for home use. Here’s a detailed breakdown of its technical specifications:

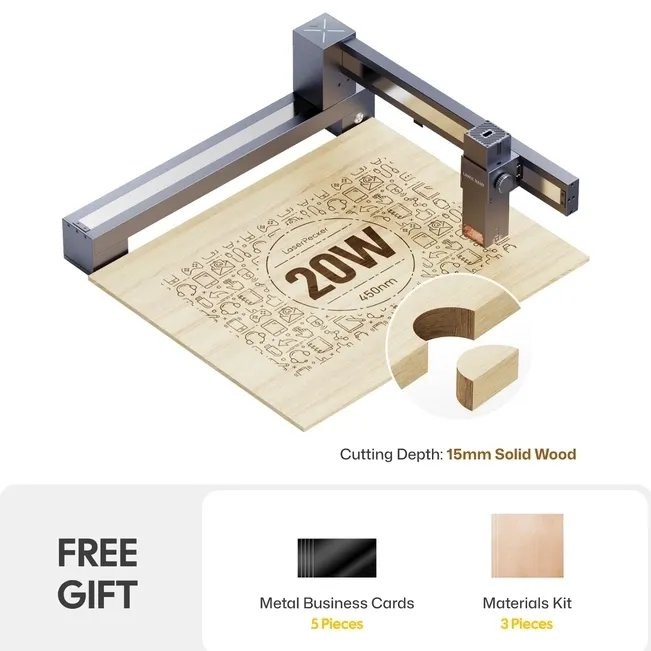

- Power Output: 20W – 60W (adjustable)

- Laser Type: CO₂ Laser

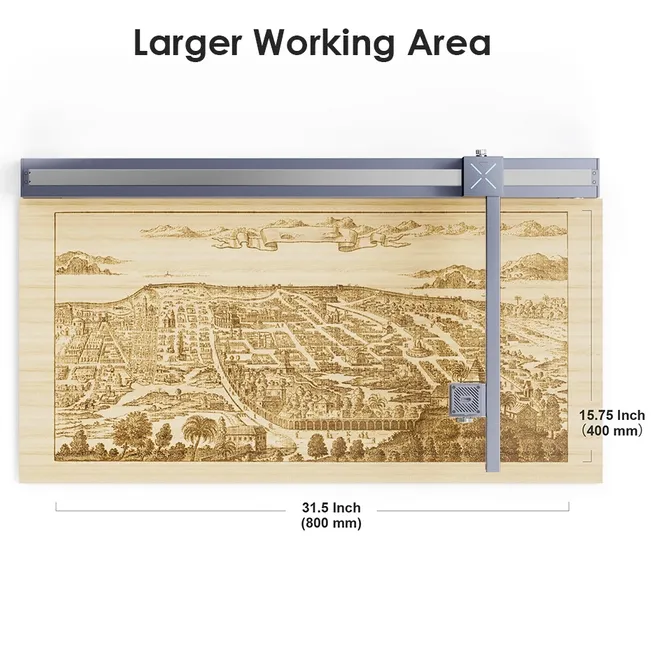

- Working Area: Up to 18” x 24”

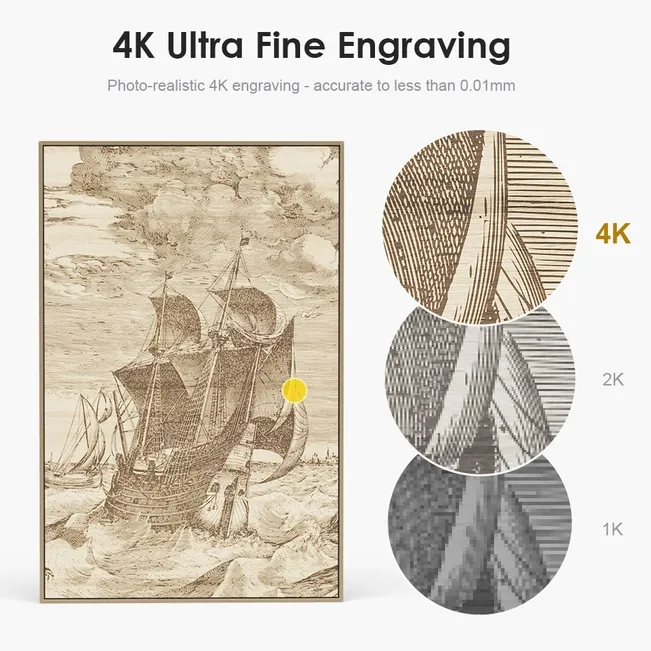

- Resolution: Up to 1200 DPI

- Engraving Speed: Up to 50 mm/s

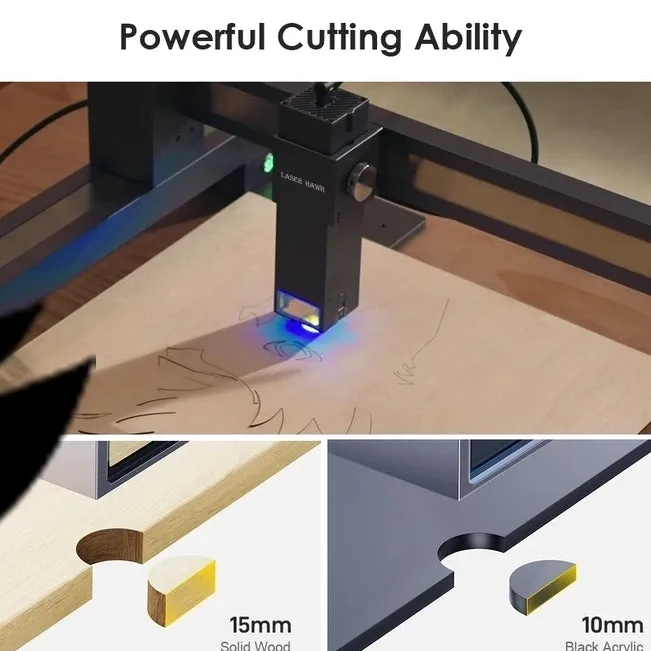

- Cutting Thickness: Supports up to 3/4” wood and other materials

- Compatibility: Works with various software, including CorelDRAW, Adobe Illustrator, and laser cutting-specific programs.

These specifications make the LaserHawk LX1 Series suitable for a wide range of projects, from small-scale engravings to detailed cutouts.

Benefits of Using a Wood Laser Cutter at Home

Precision and Accuracy

Wood laser cutters like the LaserHawk LX1 deliver precise cuts and engravings, ensuring your designs are executed flawlessly every time.

Versatility in Projects

Whether you’re creating custom furniture, decorative items, or signage, laser cutters handle a variety of materials beyond wood, including acrylic, leather, and metal.

Time Efficiency

Laser cutting significantly reduces the time required for complex projects compared to manual methods, allowing you to complete tasks faster and focus on creativity.

Top Laser Engravers for Home Use

When choosing a laser engraver for home use, consider your project requirements and budget. Here’s a list of top models:

- LaserHawk LX1 Series

-

Best for precision and versatility in wood cutting.

-

Epilog Zing 24

-

Known for its compact design and high-quality output.

-

Full Spectrum Laser MiniMend CNC

-

Ideal for small-scale projects with a focus on affordability.

-

Laserworld T-Series

- Offers robust performance for heavy-duty home use.

How to Choose the Right Wood Laser Cutter

Consider Your Project Needs

- If you’re working on large-scale projects, ensure the laser cutter has sufficient power and working area.

Software Compatibility

- Check if your preferred design software is compatible with the laser cutter. Most modern models support popular programs like CorelDRAW and Adobe Illustrator.

Budget Constraints

- Determine your budget and compare features across different models to find the best value for money.

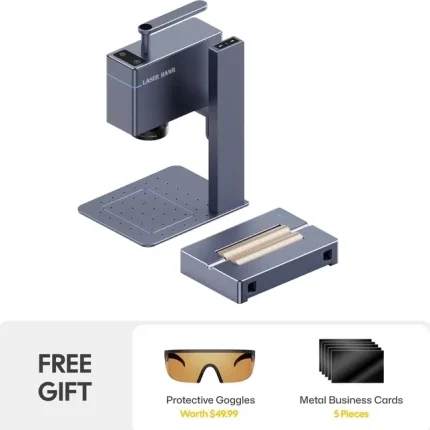

Tips for Using a Wood Laser Cutter Safely

-

Wear Protective Gear

Always wear safety glasses and gloves when operating a laser cutter. -

Ensure Proper Ventilation

Laser cutting produces fumes, so work in a well-ventilated area or use exhaust systems. -

Follow Safety Guidelines

Read the user manual thoroughly and follow all safety protocols to prevent accidents.

Common Applications of Wood Laser Cutters

Custom Furniture

Create unique designs for tabletops, chairs, and other furniture pieces with precision engraving.

Decorative Items

Design intricate patterns on wooden picture frames, coasters, and wall art.

Signage and Labels

Produce custom signs, nameplates, and labels with sharp, professional-quality engravings.

Maintenance Tips for Laser Engravers

-

Clean Regularly

Dust and debris can affect performance; clean your laser cutter after each use. -

Replace Worn Components

Check belts, mirrors, and nozzles regularly and replace them as needed to maintain optimal functionality. -

Update Firmware

Keep your laser cutter’s firmware updated for the latest features and bug fixes.

FAQ Section

1. Can I use a wood laser cutter for metals?

Yes, many wood laser cutters like the LaserHawk LX1 are capable of engraving on metals, though you may need to adjust settings depending on the material.

2. How much does it cost to maintain a laser cutter?

Maintenance costs vary based on usage and the specific model but typically include expenses for consumables like lenses, belts, and cleaning supplies.

3. Is laser cutting safe at home?

Yes, as long as you follow safety guidelines and use protective gear, laser cutting can be safely performed at home.

4. What software do I need to operate a wood laser cutter?

Most models come with compatible software or support popular design programs like CorelDRAW and Adobe Illustrator.

5. Can I engrave on different materials with the same laser cutter?

Absolutely! Laser cutters are versatile and can handle various materials, including wood, acrylic, leather, and metal.

Conclusion

A wood laser cutter is an invaluable tool for anyone looking to enhance their woodworking projects with precision and creativity. The LaserHawk LX1 Series stands out as a top choice for home use due to its powerful performance, versatility, and ease of use. By understanding the technical specifications, benefits, and safety considerations, you can make the most of this technology to bring your creative visions to life.

Whether you’re a hobbyist or a small-scale manufacturer, investing in a high-quality laser engraver like the LaserHawk LX1 Series is a smart move for elevating your woodworking game.

Miguel Tanaka –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, with fast speeds and high reliability.

Ana Weber –

This laser engraver is amazing! The engraving effects and precision are top-notch. The operation is smooth, software intuitive. Fast speeds boost efficiency. Sturdy build, highly reliable. 5 stars!

Sofia Wagner –

Absolutely stunning engravings with pinpoint accuracy! The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5/5!

Maria Schmidt –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise and stunning. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.

Luigi Hernandez –

This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!

Daisuke Torres (verified owner) –

**Performance & User Experience Review: xTool F1 Diode Laser**

The xTool F1 excels in precision (0.01mm accuracy) on wood, acrylic, and leather. Engraving birch coasters at 1000mm/min retained intricate details, while leather keychains required minimal charring at 20% power. The setup was seamless—pre-assembled with intuitive alignment guides. However, the software’s auto-tracing occasionally misinterprets complex vectors, needing manual tweaks. Air assist integration (optional) improves cut quality but adds setup time. For small businesses, its portability and <5-minute material swaps are game-changers. A minor gripe: the 12W module struggles with >6mm acrylic, limiting deep engraving projects.

Elena Schaefer (verified owner) –

The laser engraver excels in precision and versatility, particularly on wood and acrylic, delivering sharp details and smooth edges. Its 50W power ensures consistent performance, ideal for intricate designs and larger projects. The intuitive software simplifies workflow, with a user-friendly interface that supports custom templates. While it handles small-scale production efficiently, its speed could improve when working with thicker materials. Overall, it balances affordability with high-quality output, making it a solid choice for hobbyists and small businesses alike.

Erika Wilson (verified owner) –

This laser engraver excels in performance across various materials, delivering crisp results on wood, acrylic, and leather with high precision. Its speed is impressive for detailed projects like custom engravings on signage or personalized jewelry boxes. The setup was straightforward, though the learning curve requires some practice to master advanced features. For small businesses, it’s ideal for creating customized products, offering excellent ROI. While it lacks built-in cooling for heavy-duty materials, its value is undeniable for its versatility and performance-to-price ratio.

Edward Nguyen (verified owner) –

**Performance Analysis & User Experience:**

The laser engraver excels in precision across various materials. Wood and acrylic achieve crisp details with minimal adjustment, while leather requires slight power tweaks for optimal results. Speed is impressive for tight deadlines. Setup was straightforward, and the intuitive software interface allows quick project transitions. A standout feature is the customizable presets, streamlining workflow.

**Minor Suggestion:** Enhancing dust extraction would improve hygiene during prolonged use. Overall, a versatile tool with strong ROI for creative professionals.

Matthew Bruno (verified owner) –

**Laser Engraver Experience Review**

As a custom trophy manufacturer specializing in promotional products, our recent experience with the laser engraver has been transformative across multiple dimensions.

### **1. Specific Project Experience**

– **Promotional Products**: We utilized the laser engraver for personalized nameplates on trophies made from stainless steel and aluminum. The engravings were smooth and professional, enhancing the trophy’s aesthetic appeal.

– **Material Behavior and Results**: Stainless steel required careful adjustment of power settings to avoid burns due to its high reflectivity. Thicker materials demanded multiple passes at optimal speeds for clarity.

– **Unique Challenges and Solutions**: Varying material thickness and reflectivity were addressed by tweaking power, speed, and focal point settings, ensuring consistent quality across all pieces.

### **2. Business/Creative Impact**

– **Workflow Improvement**: The laser engraver significantly accelerated production, reducing the time spent on each trophy from hours to minutes compared to traditional methods.

– **Customer Feedback**: Clients have praised the precision and quality of our engravings, leading to increased satisfaction and repeat orders.

– **Return on Investment**: Despite initial costs, the tool’s efficiency has boosted productivity and profitability. A recent project involving 500 trophies was completed ahead of schedule, demonstrating its value in meeting tight deadlines without compromising quality.

This laser engraver has proven essential for maintaining high standards while enhancing our operational efficiency, making it a valuable asset to our business.

Dmitri Mitchell (verified owner) –

The LaserHawk LX1 Series is a game-changer for my wooden crafts! The precision cutting made intricate designs so much easier than ever before. It’s like having a mini workshop at home—I couldn’t be happier with the results on my latest project.

Joseph Zhang –

★★★★★ Exceptional laser engraving machine! The detail and precision are flawless. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable.