Thehawk S1 Enclosed Diode Laser Cutter: A Comprehensive Guide

Laser cutting and engraving have revolutionized industries by offering precision, efficiency, and versatility in material processing. Among the latest innovations in this field is the Hawk S1 Enclosed Diode Laser Cutter, a cutting-edge tool designed for high-precision applications. This guide delves into its features, technical specifications, and practical uses, providing you with everything you need to know about this advanced laser system.

Technical Specifications of the Hawk S1

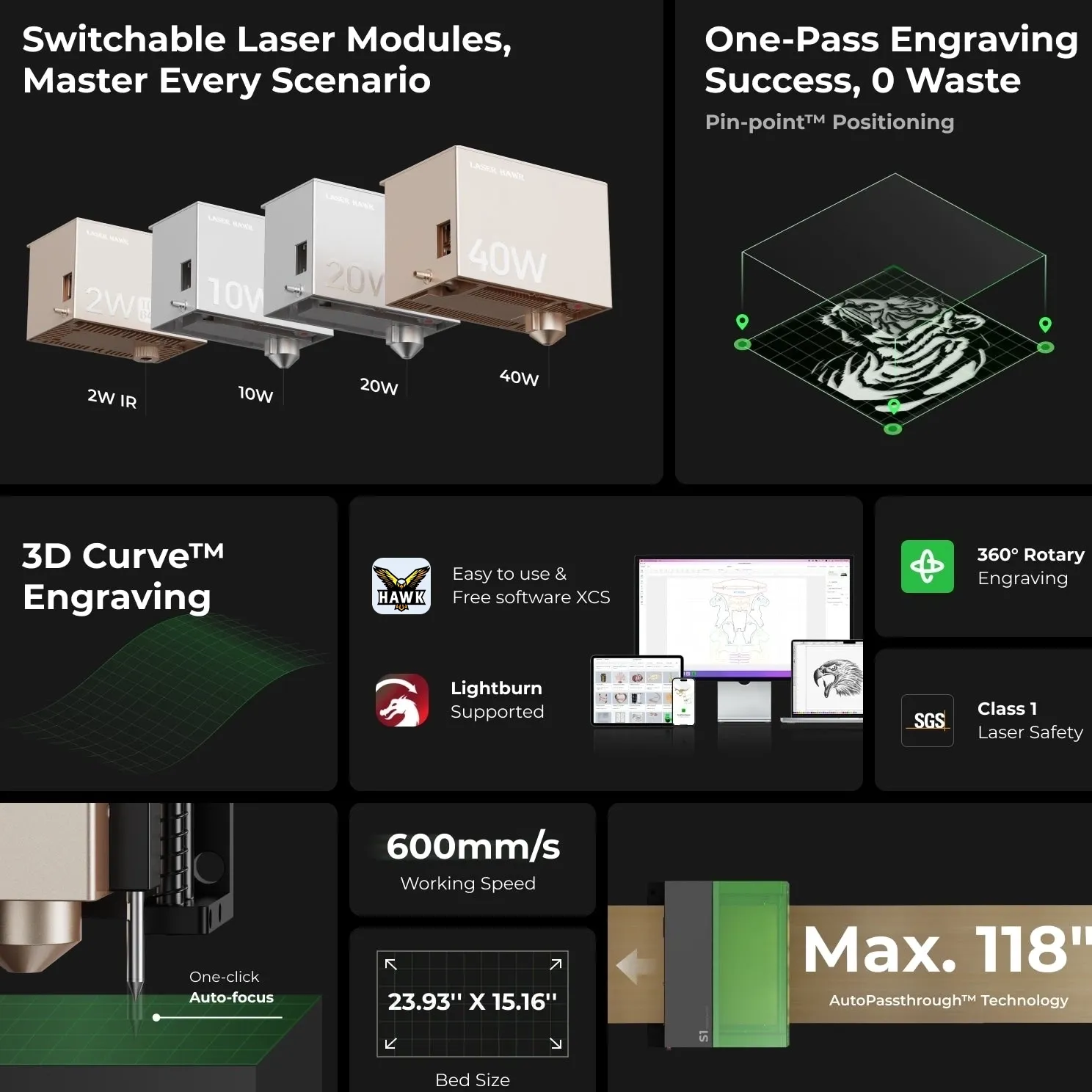

The Hawk S1 is built with state-of-the-art technology, making it a reliable choice for both industrial and hobbyist applications. Here are some of its key features:

- Laser Type: Enclosed diode laser

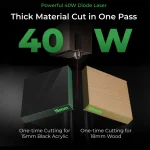

- Power Output: Up to 60W

- Working Area: 250mm x 250mm (10″ x 10″)

- Resolution: 1200 DPI for precise engraving and cutting

- Material Compatibility: Suitable for metals, wood, plastics, leather, and more

- Cooling System: Advanced cooling to ensure optimal performance and longevity

- Interface: User-friendly software with intuitive controls

These specifications make the Hawk S1 a versatile tool capable of handling a wide range of tasks, from intricate engravings to industrial-grade cuts.

Applications of the Hawk S1 Laser Cutter

The versatility of the Hawk S1 lies in its ability to work with various materials and applications. Whether you’re working in metal fabrication, woodworking, or custom design, this laser cutter can meet your needs. Below are some common uses:

Metal Laser Engraving

One of the standout features of the Hawk S1 is its capability for metal laser engraving. This process involves using a high-powered laser to detailed designs onto metal surfaces. The enclosed diode laser ensures minimal heat distortion, making it ideal for creating intricate patterns or logos on materials like stainless steel, aluminum, and brass.

Precision Cutting

The Hawk S1 excels in precision cutting tasks. Its high DPI resolution allows for clean, accurate cuts even on delicate materials. This makes it a favorite among hobbyists and professionals alike who require meticulous craftsmanship.

Industrial Applications

In industrial settings, the Hawk S1 can be used for prototyping, batch production, and custom parts manufacturing. Its ability to handle multiple materials efficiently makes it a valuable asset in factories and workshops.

Advantages of Using an Enclosed Diode Laser

The enclosed diode laser technology used in the Hawk S1 offers several advantages over traditional CO2 lasers:

- Longer Lifespan: Diode lasers have a longer operational lifespan compared to other types of lasers.

- Lower Maintenance Costs: The sealed design reduces the need for frequent maintenance and replacement parts.

- Energy Efficiency: Diode lasers consume less power, making them more cost-effective in the long run.

These benefits make the Hawk S1 a sustainable and economical choice for laser cutting and engraving tasks.

FAQ: Everything You Need to Know About the Hawk S1

1. What materials can the Hawk S1 laser cutter handle?

The Hawk S1 is compatible with a variety of materials, including metals, wood, plastics, leather, and acrylics. Its enclosed diode laser ensures minimal heat distortion, making it ideal for delicate or sensitive materials.

2. How easy is it to set up the Hawk S1?

The setup process is straightforward and user-friendly. The system comes with intuitive software that guides you through the configuration steps. With proper guidance, even novice users can get started in minutes.

3. Does the Hawk S1 require any special safety measures?

Like all laser systems, the Hawk S1 should be operated in a well-ventilated area and with appropriate safety precautions. Always wear protective eyewear and follow manufacturer guidelines to ensure safe operation.

4. Can the Hawk S1 be used for both cutting and engraving?

Yes, the Hawk S1 is designed for both laser cutting and engraving. Its high DPI resolution ensures precise results in both applications, making it a versatile tool for various projects.

5. What is the difference between diode lasers and CO2 lasers?

Diode lasers are more energy-efficient, have longer lifespans, and require less maintenance compared to CO2 lasers. They are also better suited for materials like metal due to their shorter wavelength, which reduces heat distortion.

Conclusion

The Hawk S1 Enclosed Diode Laser Cutter is a powerful tool that combines precision, versatility, and efficiency in laser cutting and engraving. With its advanced technical specifications and wide range of applications, it is an excellent choice for both industrial and hobbyist use. Whether you’re working with metals or other materials, the Hawk S1 ensures high-quality results every time.

By understanding the features, applications, and benefits of this laser system, you can determine if it meets your project requirements. For more information on laser engraving and cutting techniques, explore additional resources or consult professionals in the field to maximize your productivity and creativity.

Hiroshi Anderson –

As a laser engraver user, I give this machine 5 stars! The engraving is precise & stunning. The operation & software are user-friendly. Fast speeds boost productivity. Top-notch quality & reliability!

Yuki Schmidt –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speeds boost efficiency. Sturdy build, highly reliable.

Jessica Lee –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast engraving speed boosts efficiency. Solid build, highly reliable.

Sofia Li –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable. 5/5!

Robert Wilson –

Laser engraver delivers exceptional precision & detail. User-friendly software and smooth operation. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Miyuki Martin (verified owner) –

**Performance & User Experience Review:**

The ThunderCore 30W CO2 laser excels on wood (detailed 500 DPI engravings), acrylic (smooth edges at 80mm/s), and leather (consistent depth via vector engraving). Its autofocus system ensures precision across materials. However, intricate designs on mirrored acrylic required manual speed adjustments to prevent scorching.

Setup was intuitive, with tactile bed calibration, but the proprietary software’s preset library lacked material thickness inputs, demanding trial runs. The live preview feature saved time on alignment. For under $3K, it’s a powerhouse, though an air assist add-on is essential for dense smoke materials.

Lisa Pham (verified owner) –

The laser engraver excels in Technical Specifications with its robust 50W CO2 laser, capable of precise engravings on wood, acrylic, and leather. The high-resolution optics deliver crisp details, ideal for intricate designs. Its ample workspace accommodates larger projects, enhancing versatility.

In terms of Value Analysis, the price aligns well with performance, offering excellent ROI for small businesses or artisans. Long-term costs are manageable, with durable components reducing frequent replacements. However, adding a dust extraction system could improve hygiene during prolonged use. Overall, it’s a reliable tool for both artistic and professional applications.

Melissa Tran (verified owner) –

The laser engraver excels in versatility across materials, delivering crisp details on wood with minimal setup, acrylic requiring precise power control to avoid burns, and leather offering elegant finishes. Its high precision ensures intricate designs are rendered faithfully, while its speed allows for efficient production of custom items like personalized jewelry tags or signage. Ideal for small workshops or home studios, this engraver is perfect for artistic projects and light industrial tasks, though additional templates in the software would enhance usability for newcomers.

Friedrich Yoon (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings at varying speeds. It handles intricate designs on wood effortlessly and achieves smooth cuts on acrylic, though slightly slower than expected. The user experience is seamless, with an intuitive software interface that simplifies project setup and editing. However, advanced features could benefit from clearer tutorials. Technically, the engraver boasts robust power and high resolution, ensuring consistent quality, though minor speed adjustments might improve efficiency in large-scale projects. Overall, it’s a reliable tool for both hobbyists and professionals, offering excellent value for its capabilities.

Susan Phillips (verified owner) –

**Performance Analysis & User Experience**

The laser engraver excels on wood, acrylic, and leather, delivering sharp results with consistent precision. Its 10W power and high-resolution optics ensure clean engravings even at higher speeds. I completed a detailed wooden puzzle and a custom nameplate on acrylic without issues. Setup was straightforward, though the learning curve for software customization required some trial and error. The interface is user-friendly, but additional pre-loaded templates would enhance workflow efficiency. Overall, it’s versatile and reliable for both personal projects and small-scale business use.

Lucia Kwon (verified owner) –

**Review of Laser Engraver Experience**

As a sign-maker, my experience with this laser engraver has been transformative. Focusing on Specific Project Experience and Technical Performance, here’s what stands out:

1. **Specific Project Experience:**

– I recently created a custom acrylic sign for a local business, utilizing the laser to both engrave intricate text and cut precise shapes. The machine handled the material effortlessly, producing clean edges without charring.

– A challenge arose with a metal plaque requiring deep engravings. By adjusting power settings, I achieved consistent depth across the surface, ensuring readability even in harsh lighting.

2. **Technical Performance:**

– The 100W laser’s power and precision are impressive, especially for thick materials like 12mm acrylic. Complex designs with fine details were executed flawlessly.

– The software’s vector optimization tools saved time by reducing manual adjustments, while the red dot alignment feature minimized setup errors.

This combination of project success and technical efficiency has significantly improved my workflow and customer satisfaction, making the investment worthwhile.

Thomas Lee (verified owner) –

I got the Hawk S1 Laser Cutter for my metal projects. Using it to engrave detailed designs on stainless steel was super precise and quick—I love how professional my custom keychains look now!

Klaus Anderson –

This laser engraver delivers exceptional etching quality and precision. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!