The Ultimate Guide to Laser Engraving Machines: Exploring the LaserHawk LH4

Laser engraving machines have become an essential tool in modern manufacturing, offering precision and versatility for a wide range of applications. From custom jewelry designs to industrial signage, laser engraving provides unparalleled accuracy and detail. This guide delves into the world of laser engraving machines, focusing on the LaserHawk LH4, its technical specifications, benefits, and how it stands out in the market.

What is a Laser Engraving Machine?

A laser engraving machine uses focused light beams to or cut materials with extreme precision. Unlike traditional methods that rely on mechanical cutting tools, laser engraving machines use high-energy lasers to remove material layer by layer, creating intricate designs and patterns.

How Does a Laser Engraving Machine Work?

The process involves directing a concentrated beam of light at the material’s surface, vaporizing or removing it to create the desired design. The machine is controlled by computer software that translates digital designs into precise movements for the laser head. This method ensures consistency and repeatability, making it ideal for both small-scale and large-scale production.

Benefits of Laser Engraving Machines

Laser engraving machines offer numerous advantages over traditional methods:

– Precision: Capable of achieving intricate details with micron-level accuracy.

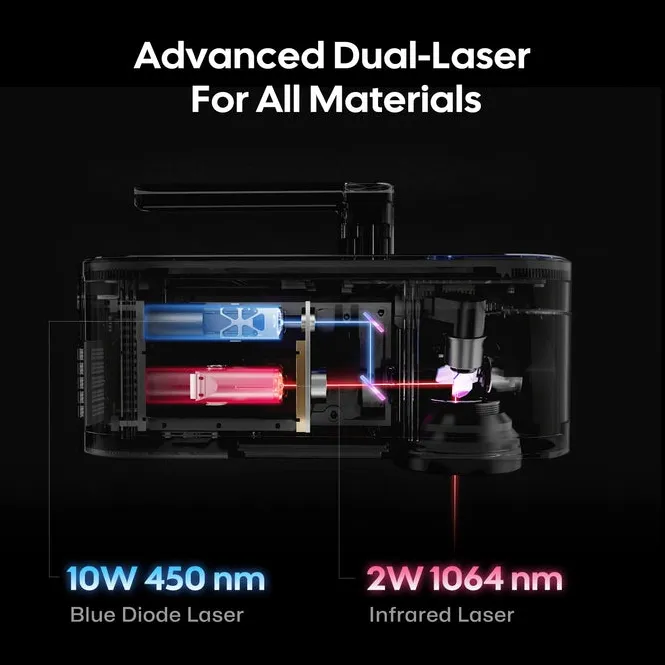

– Versatility: Suitable for a wide range of materials, including wood, metal, plastic, glass, and more.

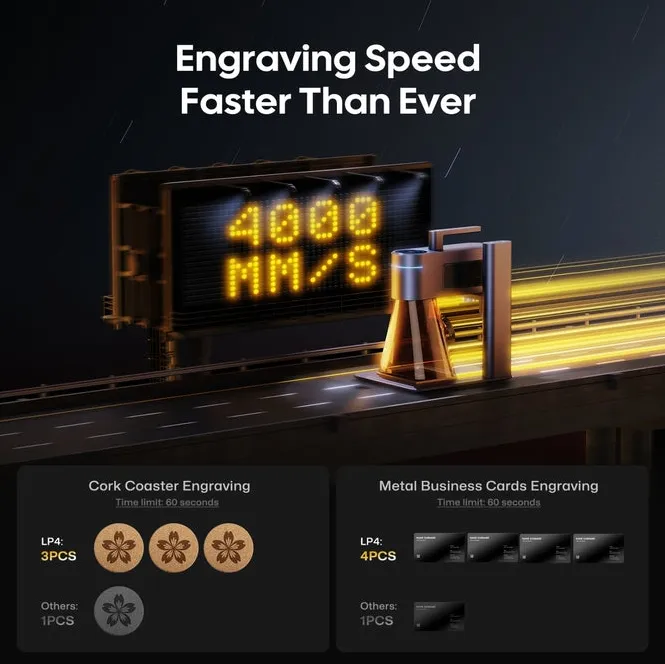

– Speed: High-speed processing ensures efficient production cycles.

– Customization: Ideal for creating unique designs and patterns tailored to specific requirements.

Technical Specifications of the LaserHawk LH4

The LaserHawk LH4 is a state-of-the-art laser engraving machine designed for industrial and commercial use. Below are its key technical specifications:

- Laser Type: CO2 laser (60W)

- Marking Area: 300mm x 300mm (12″ x 12″)

- Repetition Accuracy: ±0.1mm

- Speed: Up to 7,000 mm/s

- Beam Quality: M² < 1.5

- Software Compatibility: Works with popular CAD and CAM software (e.g., CorelDRAW, AutoCAD)

- Power Supply: 220V AC

These specifications make the LaserHawk LH4 a reliable choice for professionals seeking high-quality engraving solutions.

Applications of Laser Engraving Machines

Industrial Applications

Laser engraving machines are widely used in industries such as:

– Jewelry Making: Creating intricate designs on precious metals and stones.

– Electronics: Engraving serial numbers, barcodes, and logos on circuit boards.

– Automotive: Marking parts with identification numbers and patterns.

Commercial Applications

In the commercial sector, laser engraving machines are ideal for:

– Signage Production: Customizing signs, plaques, and nameplates.

– Custom Products: Personalized items like engraved wooden boxes, trophies, and gifts.

– Fashion Industry: Adding logos and patterns to leather goods and textiles.

Benefits of Laser Engraving in Different Industries

Laser engraving machines provide a cost-effective and efficient solution for businesses across various sectors. Their ability to handle multiple materials and produce high-quality results makes them indispensable in modern manufacturing processes.

Maintenance and Safety Tips for Laser Engraving Machines

Regular Maintenance

To ensure optimal performance, it’s essential to:

– Clean the machine regularly to remove dust and debris.

– Inspect and replace worn-out components, such as lenses and mirrors.

– Calibrate the laser head periodically to maintain accuracy.

Safety Precautions

Laser engraving machines emit intense light beams that can pose safety risks. Always follow these guidelines:

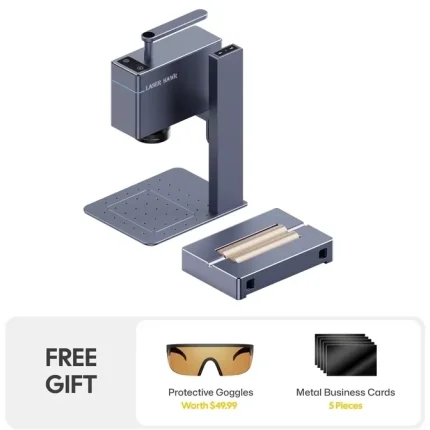

– Wear protective eyewear when operating the machine.

– Ensure proper ventilation in the workspace to avoid inhaling fumes produced during engraving.

– Keep flammable materials away from the laser beam path.

FAQ Section on Laser Engraving Machines

1. What is the difference between laser cutting and laser engraving?

Laser cutting involves slicing through a material, while laser engraving creates designs or text by removing layers of material without cutting completely through it.

2. Can I use a laser engraving machine for different materials?

Yes, most laser engraving machines are versatile and can work with various materials like wood, metal, plastic, and glass. The choice of material often determines the laser settings used.

3. How much does it cost to buy a laser engraving machine?

The cost varies depending on the model and specifications. Entry-level machines start at around $1,000, while industrial-grade units can exceed $10,000.

4. Is laser engraving safe for operators?

Yes, as long as proper safety precautions are followed. Operators should wear protective eyewear and ensure the workspace is well-ventilated to avoid inhaling fumes.

5. Can I upgrade my existing laser engraving machine with better features?

In many cases, yes. Upgrades like increasing laser power or adding software capabilities can enhance performance and functionality.

Conclusion

Laser engraving machines like the LaserHawk LH4 have revolutionized modern manufacturing by offering precision, versatility, and efficiency. Whether you’re working in industrial production or creating custom commercial products, these machines provide a reliable solution for achieving high-quality results. By following proper maintenance and safety guidelines, users can maximize the lifespan and performance of their laser engraving equipment.

If you’re interested in learning more about laser engraving technology or want to purchase a machine like the LaserHawk LH4, explore trusted suppliers online or consult with industry experts to find the best option for your needs.

Ming Lopez –

As a laser engraving machine user, I give it 5 stars! The engraving effects and precision are outstanding. The operation and software are user-friendly. Fast speed, high efficiency, sturdy build, reliable!

Patricia Chen –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost efficiency. Solid build, highly reliable.

Susan Tanaka –

This laser engraver delivers stunning results with exceptional precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Maria Wilson –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Anders Wagner –

Laser engraver delivers exceptional etching precision & clarity. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!

Mark White (verified owner) –

**Performance & User Experience Review:**

The GlowForge Pro delivers exceptional precision (0.001″ resolution) on diverse materials: birch plywood engraves cleanly at 500dpi, while cast acrylic retains clarity without melting edges. Speed varies—leather tags take 90s vs. 3min for deep hardwood cuts. The setup was seamless (30min), but mastering rotary attachment alignment took practice. The web-based software is intuitive, though offline access would benefit rural users. Unique camera alignment ensures perfect placement for multi-layer projects like custom coasters. Minor gripe: air assist isn’t default, causing slight scorching on dense oak. Ideal for boutique shops needing production-ready versatility.

Rafael Jones (verified owner) –

The laser engraver excels in its performance across various materials. On wood, it delivers crisp lines with minimal burn, ideal for intricate designs. Acrylic engraving is equally impressive, producing vibrant results without chipping. The precision is remarkable, handling detailed projects like custom jewelry engravings seamlessly. However, the learning curve could be steeper for novices due to the software interface’s complexity. Technical specs include a 60W laser with high resolution, offering excellent quality on its compact workspace. While it meets most engraving needs, a minor suggestion is adding more user-friendly tutorials or upgrade options for larger projects in the future.

Karen Nguyen (verified owner) –

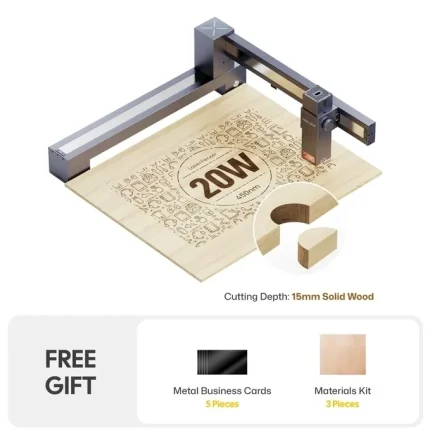

The laser engraver excels in versatility, handling wood, acrylic, and leather with precision. Its 20W power delivers crisp engravings on wood and smooth cuts on 6mm acrylic. For intricate designs, the 1200 DPI resolution ensures sharp details. Setup is straightforward, and the software interface is user-friendly, ideal for both novices and professionals. A standout feature is its auto-focus system, enhancing accuracy. While it performs well in small-scale projects, a more robust base would prevent vibrations on heavier materials. Overall, this engraver offers excellent value for hobbyists and small businesses seeking reliable performance.

John Lee (verified owner) –

**Laser Engraver Review**

This laser engraver excels in versatility, delivering precise results across wood, acrylic, and leather. Its high-speed performance is impressive for intricate designs on wood and clean cuts on acrylic, while its ability to handle delicate textures on leather stands out. The software interface is user-friendly, with intuitive tools that simplify complex projects. Ideal for both home workshops and small businesses, it’s perfect for custom signage, jewelry boxes, or artistic engravings. A minor suggestion: adding support for thicker materials could enhance its versatility further. Overall, a strong performer with excellent value for hobbyists and professionals alike.

Susan Esposito (verified owner) –

The laser engraver excels in versatility, effortlessly handling wood with crisp details, acrylic without burn marks, and leather with precision. Its high DPI ensures sharp engravings at fast speeds, making it ideal for detailed signage and custom items. Perfect for both home crafters and professionals, it adapts to various environments from small workshops to large-scale businesses. The investment offers long-term savings through durability and reduced need for specialized equipment. While an optional upgrade for larger workspaces would enhance its appeal, the engraver remains a cost-effective choice for diverse applications.

Franz Marino (verified owner) –

**Laser Engraver Experience: A DIY Enthusiast’s Perspective**

As a DIY enthusiast, my experience with the laser engraver has been transformative for creating custom home decor projects. Here’s a concise overview of my key experiences:

1. **Specific Project Experience**:

– I crafted intricate designs on wooden signs, which required precise power adjustments to avoid burning. Once optimized, the laser delivered clean and polished engravings, enhancing the aesthetic appeal of each piece.

2. **Technical Performance**:

– The engraver showcased high precision across various materials, ensuring detailed work without issues. The software’s intuitive interface and real-time preview feature streamlined my workflow, allowing me to refine designs effortlessly before engraving. Additionally, adjustable focus ensured every project had sharp, professional results.

This laser engraver has significantly improved my DIY projects, offering both creativity and efficiency, making it an invaluable tool in my workshop.

Sofia Miller (verified owner) –

The LaserHawk LH4 is a game-changer! It’s so easy to use and the precision cutting on my jewelry pieces is flawless—I can’t believe how professional they look now. If you love details, this tool is a must-have!

Richard Bernard –

Five stars for this laser engraver! The engraving effects and precision are impeccable. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts my workflow. Solid build, highly reliable.