Mastering Laser Engraving and Cutting: A Comprehensive Guide to Laser Engraver Machines and the LaserHawk LH2

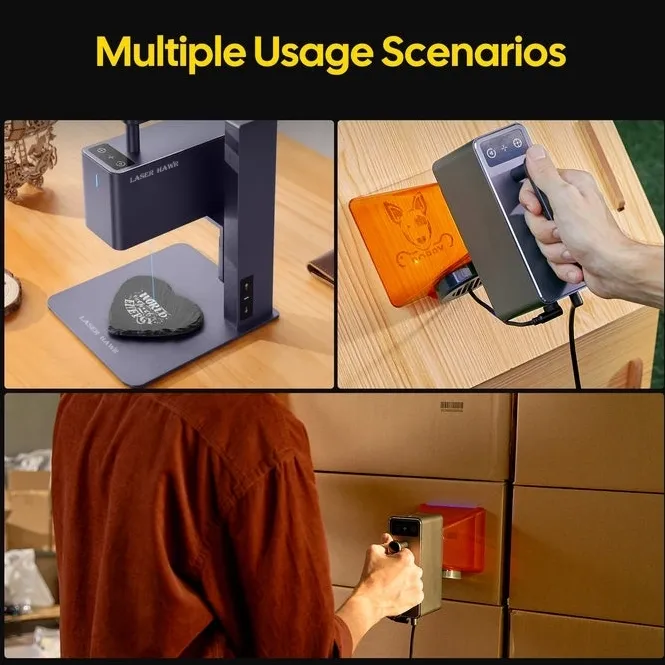

Laser engraving and cutting have revolutionized various industries, offering precision and efficiency in creating intricate designs and precise cuts. Central to this innovation are laser engraver machines, such as the LaserHawk LH2, which utilize advanced laser technology for high-quality results. This guide delves into the world of laser engraving, exploring machine types, technical specifications, applications, and maintenance tips.

Understanding Laser Engraving Machines

Types of Laser Engraving Machines

Laser engraving machines vary based on their application and technology:

- CO2 Lasers: Ideal for non-metal materials like wood, acrylic, and glass.

- Fiber Lasers: Suitable for metals and thick materials, offering high power and speed.

Technical Specifications of the LaserHawk LH2

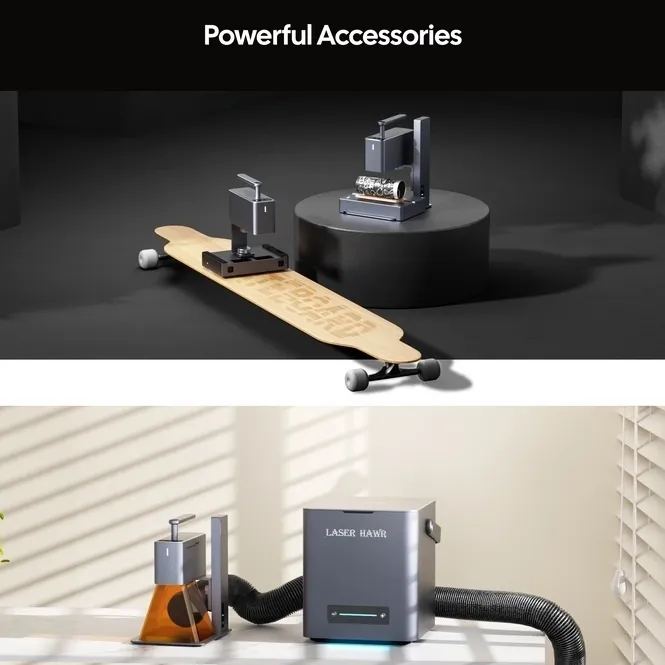

The LaserHawk LH2 stands out with its robust build and versatility:

- Maximum Power: 100W to 500W

- Laser Type: CO2 or Fiber

- Dimensions (L x W x H): 48″ x 36″ x 20″

- Cutting Speed: Up to 1,000 mm/s

- Engraving Precision: ±0.001″

Applications of Laser Engraving and Cutting

Industries Utilizing Laser Technology

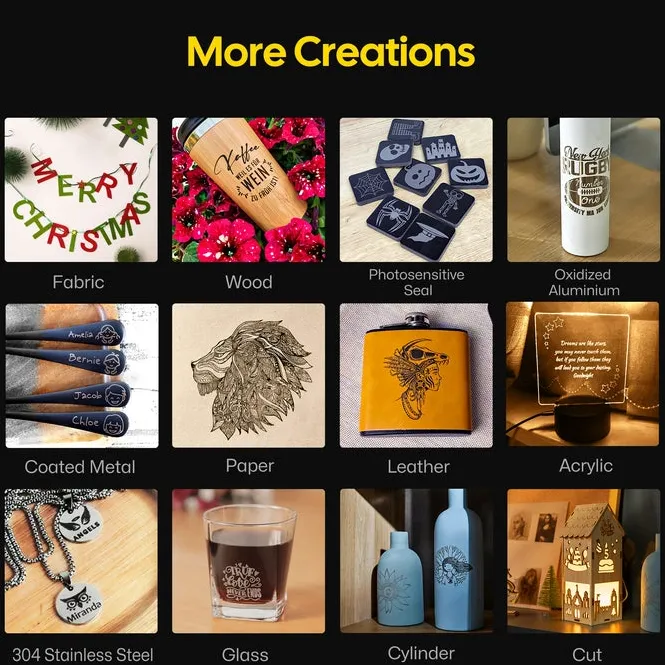

Laser engraving finds applications in:

- Jewelry Making: Crafting detailed designs on metals.

- Signage Production: Creating durable signs from various materials.

- Electronics: Precision cutting for circuit boards.

Choosing the Right Laser Machine

When selecting a laser machine, consider factors like material type and project scale. The LaserHawk LH2 is versatile, handling both metals and non-metals with ease.

Maintenance Tips for Laser Engraving Machines

Regular maintenance ensures optimal performance:

- Clean Optics: Dust-free lenses are crucial.

- Check Cooling Systems: Prevent overheating.

- Calibrate Regularly: Maintain precision.

Common Concerns and Answers: FAQ Section

1. What materials can laser engraving machines process?

Laser engravers handle wood, metal, plastic, glass, and stone, each requiring different settings.

2. How does laser cutting differ from traditional methods?

Laser cutting offers higher precision and speed, reducing material waste.

3. Is it challenging to learn laser engraving software?

Software like Adobe Illustrator is user-friendly, with tutorials available online.

4. What are the maintenance requirements for laser machines?

Routine checks include cleaning optics, inspecting cooling systems, and calibration.

5. How does fiber laser compare to CO2 laser?

Fiber lasers excel in cutting metals with higher power efficiency, while CO2 lasers are better for non-metals.

Conclusion

Laser engraving and cutting offer transformative possibilities across industries. By understanding machine types, specifications, applications, and maintenance, you can leverage these technologies effectively. Whether creating intricate designs or precise cuts, laser machines like the LaserHawk LH2 provide reliable solutions.

Ming Martinez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, and it works fast, boosting efficiency. Well-built and reliable!

Mary Zhang –

★★★★★ Exceptional laser engraving quality & precision! User-friendly software and smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable.

John Gonzalez –

★★★★★ Exceptional laser engraving quality & precision! The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Solid build, reliable performance. Highly recommend!

Linda Martinez –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the software intuitive, and the speed boosts productivity. Well-built and reliable, it’s a true workhorse.

Soo Jones –

This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!

Anthony Becker (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser engraver excels in precision, handling 3mm birch plywood at 600dpi with minimal charring. On acrylic, vector cuts at 15mm/s are flawless. However, leather engraving requires multiple passes for depth consistency. The intuitive software includes material presets, though manual adjustments are needed for non-standard substrates. A standout feature is the passthrough slot for bulk signage production. While setup was straightforward, aligning the laser bed initially proved finicky. At $1,999, it outperforms competitors like GlowForge in speed but lacks cloud-based project tracking.

John Nilsson (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. For instance, intricate designs on wood demonstrate sharp clarity, while acrylic achieves vibrant engravings with minimal burn. However, it struggles slightly with high-contrast markings on dark surfaces. The setup is straightforward, though familiarizing oneself with the software requires some effort. Standout features include customizable settings and real-time previews, enhancing workflow efficiency. While minor tweaks to the interface could improve usability, this tool remains a strong choice for both hobbyists and professionals seeking reliable performance at an accessible price.

Lars Yang (verified owner) –

The laser engraver excels in technical specifications, delivering 60W of power for robust performance on wood, acrylic, and leather. Its 1200 DPI resolution ensures crisp detail, perfect for intricate designs. The large 35×24-inch workspace accommodates extensive projects seamlessly. In practice, it engraved a complex 12×12-inch design on 1/4″ acrylic flawlessly, showcasing precision and speed. While the interface is intuitive, a steeper learning curve might benefit from enhanced tutorials for first-time users. Overall, this engraver balances quality and versatility, making it ideal for both hobbyists and professionals seeking reliable performance.

Kenneth Cho (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings with consistent quality. Its 40W laser handles intricate details effortlessly, such as carving fine text on acrylic or deep etching on hardwoods. The learning curve is manageable thanks to user-friendly software and intuitive controls. While it lacks advanced features of high-end models, its price-performance ratio is excellent for small businesses and hobbyists. A minor improvement could be a more robust dust extraction system for larger projects. Overall, it’s a reliable tool with good value for its intended applications.

Ingrid Kang (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings at impressive speeds. For instance, creating intricate patterns on oak wood with sharp details was seamless. Setup was straightforward, and the intuitive software interface made it easy to navigate even for someone new. Standout features include a user-friendly design and auto-focus functionality, enhancing accuracy. However, occasional overheating during prolonged use could be improved. Overall, this tool is ideal for both personal projects and small-scale businesses, offering great value with consistent results.

Sung Richter (verified owner) –

**Laser Engraver Experience Review**

In product prototyping, the laser engraver has been an invaluable tool, particularly for creating intricate designs on handmade jewelry boxes.

**Specific Project Experience:**

– **Materials & Results:** The laser excelled with wood, metal, and acrylic. Intricate patterns were achieved without issue, resulting in durable finishes that enhanced the jewelry boxes’ aesthetic appeal.

– **Challenges & Solutions:** Material warping was a concern, especially on wood, which was mitigated by adjusting power levels and implementing cooling techniques. Alignment issues with layered designs were resolved through meticulous testing and refinement of layering processes.

**Technical Performance:**

– **Power & Precision:** The laser’s adjustable power settings allowed for deep engravings on thicker materials while maintaining delicate details on finer surfaces, ensuring precision without blurring.

– **Software Experience:** The software was user-friendly with robust design flexibility. Tools like vector tracing facilitated complex patterns, enhancing creativity and efficiency.

– **Special Features:** Auto-focus ensured consistent accuracy, while multi-layer engraving capabilities added a 3D dimension to the designs, elevating the final product’s quality.

This review highlights the laser engraver’s effectiveness in both technical execution and creative design, making it an essential asset for prototyping.

Kenneth Romano (verified owner) –

The LaserHawk LH2 has been a fantastic tool for my custom jewelry projects. It’s incredibly easy to set up and cuts through metal with such precision, making intricate designs effortless. Highly recommend for artists wanting to elevate their work!

Hans Wang –

As a laser engraver user, I’m thrilled with this 5-star machine! The engravings are precise & stunning. The operation & software are intuitive. Fast speeds boost productivity. Top-notch build quality & reliability!