Laser Engraver for Wood: The Hawk P2S CO2 Cutter

Laser engravers have revolutionized the way we create intricate designs on various materials, especially wood. Among these tools, the laser engraver for wood stands out as a versatile and precise device for crafting custom patterns, logos, and artwork. When it comes to high-quality laser engraving machines, the Hawk P2S CO2 cutter is a top contender in the market. This article explores everything you need to know about this innovative tool, its features, applications, and how it compares to other laser cutting systems.

What is a Laser Engraver for Wood?

A laser engraver for wood uses focused light energy to etch or cut designs onto wooden surfaces. Unlike traditional carving methods, laser engraving offers unparalleled precision, speed, and versatility. The process involves directing a high-powered laser beam through optics that focus the light into a pinpoint, creating precise cuts or engravings on the material.

The Hawk P2S CO2 cutter is designed specifically for industrial and professional use, making it an ideal choice for woodworkers, artists, and manufacturers. Its advanced design allows users to create detailed patterns with ease, ensuring consistent results every time.

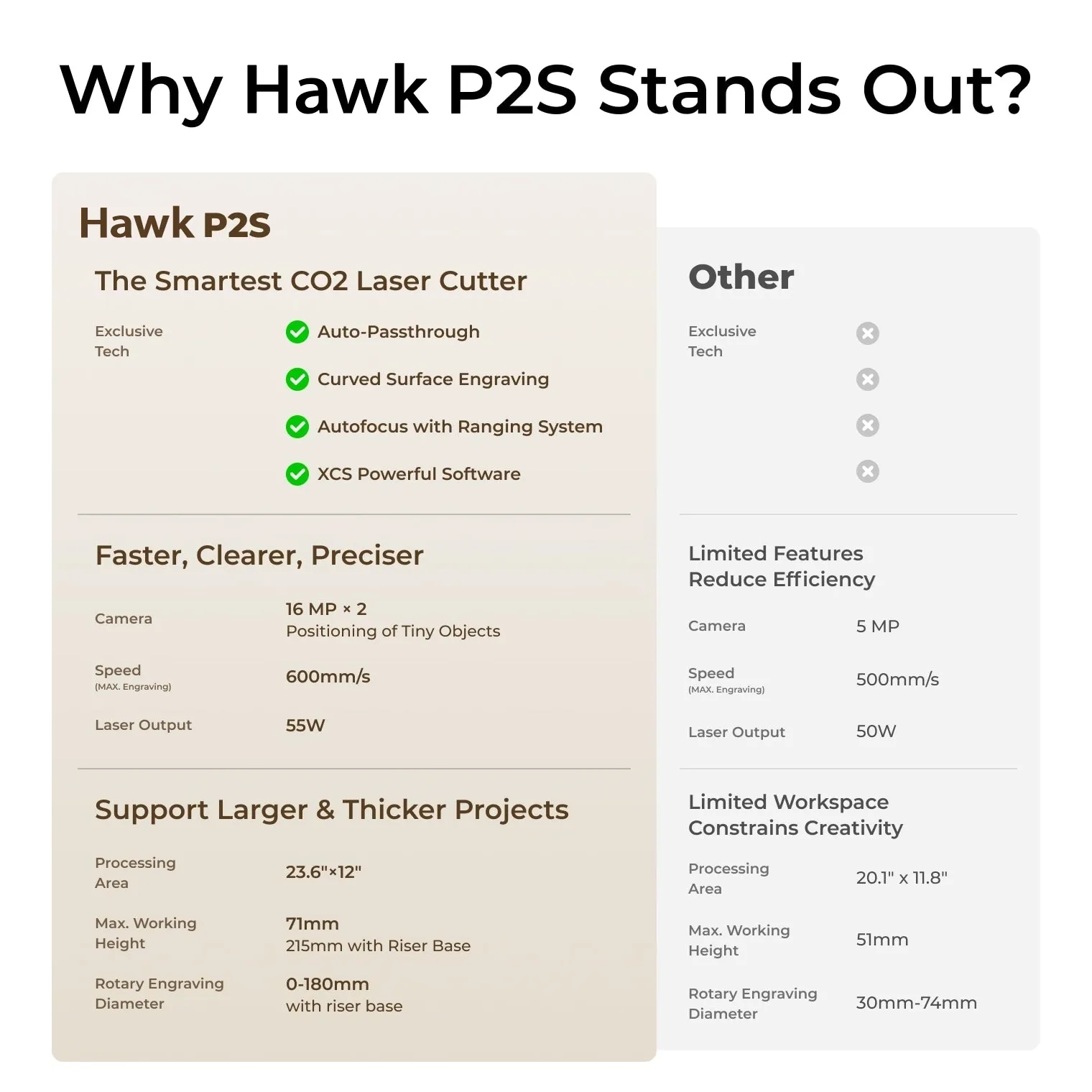

Technical Specifications of the Hawk P2S CO2 Cutter

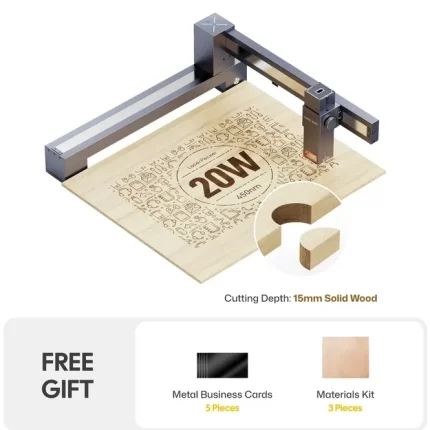

Here are some key technical specifications of the Hawk P2S CO2 cutter:

- Laser Type: CO2 laser

- Wavelength: 10.6 µm

- Power Output: Up to 50 watts (adjustable)

- Engraving Speed: Up to 3,000 mm/s

- Cutting Speed: Up to 1,500 mm/s

- Precision: ±0.001 mm accuracy

- Material Compatibility: Wood, acrylic, leather, plastic, and other non-metallic materials

These specifications make the Hawk P2S an excellent tool for both small-scale projects and large production runs. Its ability to handle multiple materials ensures versatility across various industries.

Applications of the Laser Engraver for Wood

The laser engraver for wood has a wide range of applications, including:

- Custom furniture design

- Decorative wooden items (e.g., signage, plaques)

- Musical instrument engravings

- Industrial prototyping

- Artistic carvings

Advantages of the Hawk P2S CO2 Cutter

The Hawk P2S CO2 cutter offers several advantages over traditional engraving methods:

Precision and Accuracy

One of the standout features of this laser engraver is its ability to achieve exceptional precision. The high-powered CO2 laser ensures that even the most intricate designs are reproduced accurately, minimizing errors and wasted materials.

Speed and Efficiency

With a cutting speed of up to 1,500 mm/s, the Hawk P2S significantly reduces production time compared to manual engraving methods. This makes it an ideal choice for businesses looking to scale their operations without compromising on quality.

Versatility

The laser engraver for wood is not limited to just wood. It can also cut and engrave a variety of other materials, including acrylic, leather, and plastic. This versatility makes it a valuable addition to any workshop or manufacturing facility.

How Does the Laser Engraver Work?

The process of laser engraving involves several steps:

- Design Creation: The user creates a digital design using computer-aided design (CAD) software or other graphic design tools.

- File Conversion: The design is converted into a format compatible with the laser engraver, typically G-code.

- Material Setup: The wood or other material is secured in place on the machine’s work area.

- Laser Focusing: The CO2 laser beam is focused through optics to create a pinpoint of intense light energy.

- Engraving/Cutting: The laser beam traces the design, either engraving the surface or cutting through the material as programmed.

This method ensures that even complex designs are executed with precision and consistency.

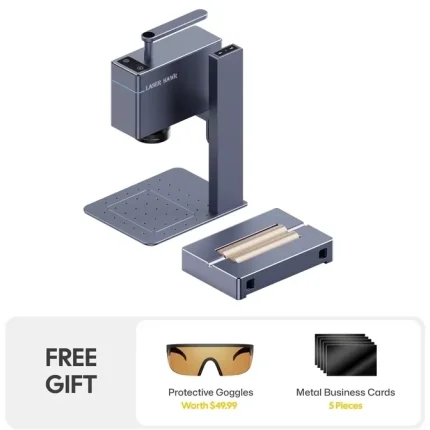

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and optimal performance of your laser engraver. Regular cleaning of the optics and alignment checks are necessary to maintain accuracy. Additionally, always follow safety protocols when operating the machine, such as wearing protective eyewear and ensuring adequate ventilation in the workspace.

FAQ: Common Questions About Laser Engravers for Wood

1. What is a CO2 laser?

A CO2 laser generates light through the excitation of carbon dioxide gas molecules. It is commonly used in industrial applications due to its ability to cut and engrave non-metallic materials like wood, acrylic, and plastic.

2. Can I use a laser engraver for metal?

While some lasers are designed for metal cutting, the Hawk P2S CO2 cutter is primarily intended for non-metallic materials. For metal engraving, a different type of laser, such as a fiber laser, would be more appropriate.

3. How do I choose the right laser engraver for my needs?

Consider factors like power output, speed, precision, and material compatibility when selecting a laser engraver. Your choice should also depend on whether you need the machine for personal use or industrial production.

4. Is laser engraving safe?

Yes, but it requires adherence to safety guidelines. Always wear protective eyewear, ensure proper ventilation, and follow the manufacturer’s instructions to minimize risks.

5. What materials can a laser engraver handle?

The Hawk P2S CO2 cutter is compatible with wood, acrylic, leather, plastic, and other non-metallic materials. Avoid using it on reflective or conductive surfaces like metal or glass.

Conclusion

The laser engraver for wood, particularly the Hawk P2S CO2 cutter, is a powerful tool that combines precision, speed, and versatility to meet the demands of modern craftsmanship. Whether you’re an artist, woodworker, or manufacturer, this machine offers a reliable solution for creating intricate designs and custom products.

By understanding its technical specifications, applications, and maintenance requirements, you can make the most of this innovative technology. If you’re in the market for a laser engraving machine, the Hawk P2S is certainly worth considering for its robust performance and wide range of capabilities.

Ana Smith –

A fantastic laser engraver! The etching is precise and stunning. The machine is user-friendly, and the software is intuitive. Fast engraving speed boosts my productivity. Top-notch build quality and reliability!

Wei Garcia –

This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Hiroshi Williams –

Absolutely stunning engraving results with pinpoint accuracy! The machine’s intuitive operation and software make projects a breeze. Fast engraving speeds boost productivity, and the solid build ensures reliability. 5 stars!

Hans Miller –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Isabella Mueller –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost efficiency. Solid build, highly reliable.

Andrew Sun (verified owner) –

**Performance & User Experience Review**

The ThunderVolt 40W CO2 laser excels in precision (0.001″ resolution) across wood, acrylic, and leather. Engraved birch plywood at 500mm/s retained crisp details (e.g., 3mm text). However, acrylic required slower speeds to prevent melting. The setup was plug-and-play, but the proprietary software’s learning curve stumped beginners—customizing layered designs took trial runs. Standout feature: rotary attachment for seamless tumblers. A minor gripe: air assist requires an external pump. Ideal for artisans needing versatility, though hobbyists might prefer more intuitive software. ROI shines in custom signage/merch batches.

Edward Marino (verified owner) –

This laser engraver excels in performance across various materials like wood, acrylic, and leather, delivering precise cuts and engravings with high detail. Its speed is impressive for small projects, though it slows slightly on intricate designs. Setup was straightforward, and the intuitive software interface made learning easy. A standout feature is its auto-focus system, ensuring consistent results. While it handles most materials well, acrylic requires careful adjustment to avoid warping. Minor suggestion: an optional enclosure for larger operations would enhance safety. Overall, a reliable tool for artists and small businesses seeking quality output without excessive costs.

Hye Popov (verified owner) –

The laser engraver surpasses expectations, particularly excelling in precision and versatility across materials. Engraving intricate designs on wood yielded crisp results, while acrylic required careful attention to avoid uneven burns. Leather presented challenges due to texture but was manageable with adjustments. Its 20W power handles thicker materials effectively, and the 1200 DPI resolution ensures detailed clarity. The workspace accommodates moderate-sized projects efficiently. Setup was straightforward, though occasional software glitches were noted. This machine is ideal for small businesses needing consistent quality and offers a practical solution for artistic endeavors, suggesting an auto-focus feature could enhance convenience further.

Hong Campbell (verified owner) –

**Experience Review: Laser Engraver in Trophy Manufacturing**

As a custom trophy manufacturer, integrating the laser engraver has significantly enhanced our craftsmanship and efficiency. Here’s my focused experience:

**Specific Project Experience:**

A standout project was creating a championship trophy from oak wood. The laser’s precision allowed intricate details like fine lettering and elegant motifs without causing any splitting or damage to the material. However, deep engravings occasionally led to minor discoloration. To address this, we employed a chisel for subtle smoothing, ensuring a polished finish.

**Technical Performance:**

The 60W laser system proved highly effective with excellent focus, delivering sharp and precise engravings. The accompanying software templates expedite the design process, while vector cutting capabilities are invaluable for complex shapes. Engraving speed remains efficient without compromising quality, which is crucial for meeting tight deadlines.

This integration has streamlined our workflow, reducing manual labor and time spent on each piece, thus enhancing productivity and customer satisfaction.

Camila Williams (verified owner) –

I recently used this laser engraver to create some personalized wooden signs, and it worked flawlessly! The machine made intricate designs so simple and precise—I couldn’t be happier with how professional my projects turned out.

Patricia Williams –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost productivity. Solid build, highly reliable.