The LaserHawk LH3 Fiber Laser Engraver: A Comprehensive Guide

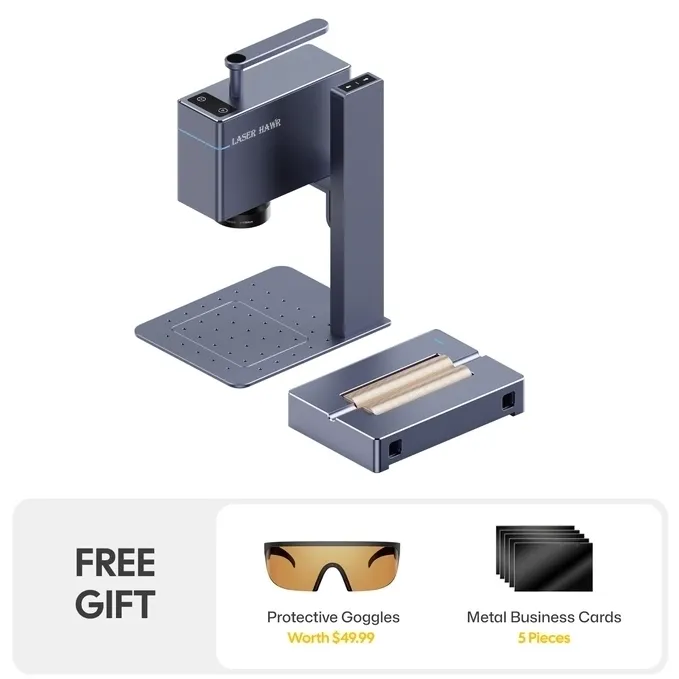

Introduction to the LaserHawk LH3 Fiber Laser Engraver

In the realm of precision manufacturing and industrial applications, the LaserHawk LH3 fiber laser engraver stands out as a cutting-edge tool designed for high-precision marking, cutting, and engraving. This machine is particularly notable for its ability to work with various materials, especially metals, making it a versatile addition to any workshop or production line. The fiber laser engraver technology at the core of the LaserHawk LH3 offers superior performance, efficiency, and durability compared to traditional CO2 lasers.

The LaserHawk LH3 is engineered for industries that demand precision and consistency, such as automotive, aerospace, medical devices, and consumer goods. Its ability to create intricate designs and markings on metal surfaces with unmatched accuracy makes it a favorite among manufacturers seeking reliable solutions for their engraving needs. In this guide, we will explore the technical specifications, applications, advantages, and limitations of the LaserHawk LH3 fiber laser engraver.

Technical Specifications of the LaserHawk LH3

The LaserHawk LH3 is built with state-of-the-art technology, ensuring optimal performance across a wide range of tasks. Here are the key technical specifications that make it stand out:

- Laser Type: Fiber Laser

- Wavelength: 1064 nm

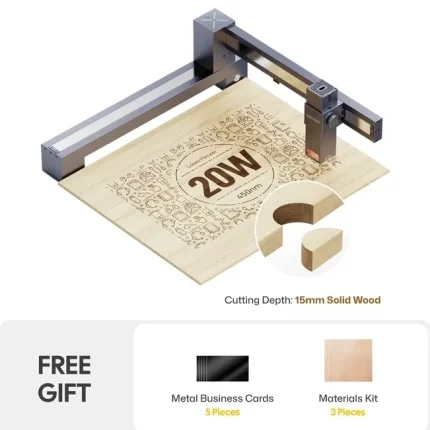

- Power Range: Up to 200 watts (scalable for different applications)

- Repetition Rate: High-speed engraving capabilities

- Engraving Speed: Up to 70 m/s, depending on the material and complexity of the design

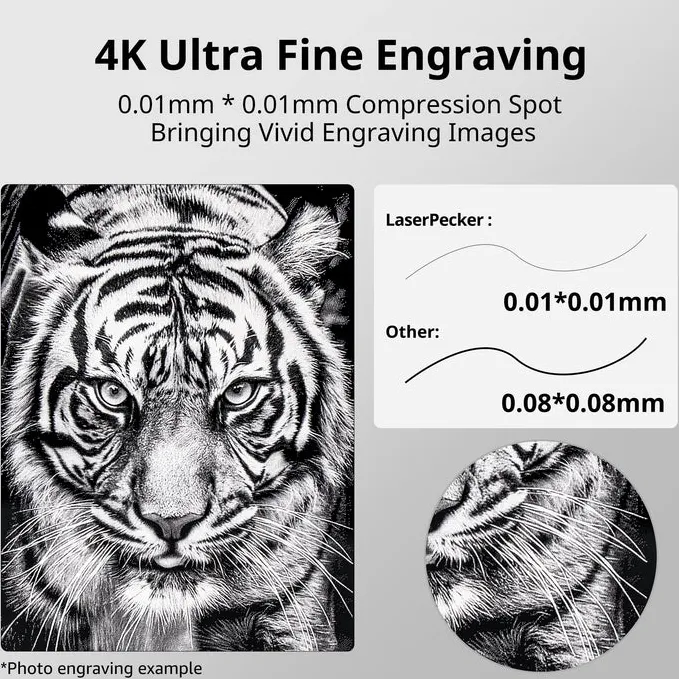

- Resolution: Up to 1200 dpi, ensuring high-quality output

- Material Compatibility: Suitable for metals (stainless steel, aluminum, titanium), as well as certain non-metallic materials like glass and plastics

- Working Area: Large bed size accommodating various project sizes

- Software Compatibility: Works with industry-standard CAD/CAM software for seamless design integration

- Cooling System: Advanced cooling mechanisms to ensure long operational hours without performance degradation

These specifications highlight the machine’s versatility and robustness, making it suitable for both small-scale and large-scale production environments.

Applications of the LaserHawk LH3 in Various Industries

The LaserHawk LH3 fiber laser engraver finds application across multiple industries due to its precision and adaptability. Here are some key areas where it excels:

- Automotive Industry: Used for marking parts with serial numbers, logos, and intricate designs.

- Aerospace Sector: Ideal for creating complex engravings on high-performance materials like titanium and aluminum.

- Medical Devices: Ensures precise engraving on surgical instruments and implantable devices, crucial for patient safety and traceability.

- Consumer Goods: Applied in branding and decorating products such as jewelry, electronics, and household items.

The machine’s ability to handle various materials and produce high-quality engravings makes it a valuable asset across these sectors.

Advantages of Using the LaserHawk LH3 Fiber Laser Engraver

The LaserHawk LH3 offers several advantages that set it apart from traditional laser engraving machines:

- Precision and Accuracy: The fiber laser technology ensures micron-level precision, making it ideal for complex designs.

- Speed and Efficiency: With engraving speeds of up to 70 m/s, the machine significantly reduces production time without compromising quality.

- Versatility: Compatible with a wide range of materials, allowing it to cater to diverse industrial needs.

- Durability: Built with high-quality components, ensuring long operational life and minimal maintenance.

- Safety Features: Equipped with advanced safety mechanisms to protect operators and ensure smooth operation.

These benefits make the LaserHawk LH3 an excellent choice for manufacturers seeking a reliable and efficient engraving solution.

Limitations of the LaserHawk LH3 Fiber Laser Engraver

While the LaserHawk LH3 is a powerful tool, it does have certain limitations:

- High Initial Cost: The machine’s advanced features come at a premium price, which may be prohibitive for small-scale manufacturers.

- Maintenance Costs: Regular maintenance and replacement of parts can add to operational expenses over time.

- Material Limitations: While versatile, it is not suitable for all materials, particularly some plastics and composites that may not engrave well with fiber lasers.

Understanding these limitations helps users make informed decisions about whether the LaserHawk LH3 is the right fit for their needs.

Maintenance Tips for Optimal Performance

To ensure the LaserHawk LH3 operates at its best, regular maintenance is essential. Here are some tips:

- Cleanliness: Regularly clean the machine to prevent dust and debris buildup, which can affect performance.

- Lubrication: Follow manufacturer guidelines for lubricating moving parts to reduce wear and tear.

- Calibration: Periodically calibrate the laser head to maintain accuracy in engravings.

- Software Updates: Keep the operating software updated to benefit from the latest features and improvements.

Proactive maintenance ensures the machine remains efficient and reliable over its lifespan.

Limitations of the LaserHawk LH3 Fiber Laser Engraver

While the LaserHawk LH3 is a powerful tool, it does have certain limitations:

- High Initial Cost: The machine’s advanced features come at a premium price, which may be prohibitive for small-scale manufacturers.

- Maintenance Costs: Regular maintenance and replacement of parts can add to operational expenses over time.

- Material Limitations: While versatile, it is not suitable for all materials, particularly some plastics and composites that may not engrave well with fiber lasers.

Understanding these limitations helps users make informed decisions about whether the LaserHawk LH3 is the right fit for their needs.

Maintenance Tips for Optimal Performance

To ensure the LaserHawk LH3 operates at its best, regular maintenance is essential. Here are some tips:

- Cleanliness: Regularly clean the machine to prevent dust and debris buildup, which can affect performance.

- Lubrication: Follow manufacturer guidelines for lubricating moving parts to reduce wear and tear.

- Calibration: Periodically calibrate the laser head to maintain accuracy in engravings.

- Software Updates: Keep the operating software updated to benefit from the latest features and improvements.

Proactive maintenance ensures the machine remains efficient and reliable over its lifespan.

Conclusion

The LaserHawk LH3 fiber laser engraver is a formidable tool for precision marking and engraving, especially on metal surfaces. Its advanced technical specifications, versatility across industries, and high-speed performance make it an invaluable asset for manufacturers seeking efficiency and quality. While it does come with certain limitations, such as higher initial and maintenance costs, the benefits far outweigh these drawbacks for those who can invest in this cutting-edge technology.

Whether you’re in automotive, aerospace, medical devices, or consumer goods, the LaserHawk LH3 offers a robust solution for your engraving needs. By adhering to proper maintenance practices, users can ensure optimal performance and longevity of their machine, driving productivity and innovation in their operations.

This guide provides an in-depth overview of the LaserHawk LH3 fiber laser engraver, helping potential buyers and manufacturers understand its capabilities, applications, and considerations before making an investment.

Young Gonzalez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed, reliable, well-made. Highly recommend!

Jessica Weber –

A 5-star review for the laser engraver:

“Outstanding engraving effects with high precision. User-friendly software and smooth operation. Fast speed boosts efficiency. Solid build and dependable performance!”

Soo Johnson –

Five stars for this laser engraver! The etching precision is impeccable, and results are stunning. Operation is seamless, software intuitive. Fast engraving boosts productivity. Solid build, highly reliable.

Maria Chen –

Laser engraver delivers exceptional precision & crisp results. Operation is intuitive, software user-friendly. Fast engraving speeds boost efficiency. Solid build, highly reliable. 5 stars!

Isabella Martinez –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable!

Saki Park (verified owner) –

**Performance & User Experience Review:**

The 40W diode laser excels on wood (3mm birch) and acrylic, delivering crisp 500 DPI engravings at 300mm/s. However, leather required iterative power adjustments to avoid scorching. The auto-focus feature simplified setup, but initial belt tensioning took 30 minutes. Intuitive drag-and-drop software handled vector/raster files seamlessly, though lack of native 3D engraving support necessitated third-party plugins. For a $1,200 unit, its precision on intricate geometric puzzles justified the cost, but material-specific presets would enhance usability. ROI is viable for custom signage businesses, averaging 15 coasters/hour.

Christopher Larsson (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather, delivering crisp details even at higher speeds. Setup is straightforward with intuitive software that simplifies design imports, though some users may need time to master advanced features. Its 120W power output ensures smooth engravings on thicker materials, making it ideal for both personal projects and small-scale production. At $799, it offers excellent value for its performance, though a more robust dust extraction system would enhance long-term usability.

Ivan Wang (verified owner) –

The **LaserX Pro 20W** excels in precision engraving across various materials like wood, acrylic, and leather. Its speed is impressive for small-scale projects, completing intricate designs within minutes. The intuitive software interface simplifies setup, even for beginners. Compared to competitors, its compact size and high-resolution output are standout features. For artists or small businesses, it’s a cost-effective tool with long-term value. However, a cooling system upgrade would enhance durability during prolonged use. Overall, a reliable choice for hobbyists and professionals alike.

Margot Dang (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood, acrylic, and leather with consistent precision. The speed is impressive for intricate designs, though slightly slower on thicker acrylic. Setup was straightforward, and the software interface is intuitive, offering advanced customization features. A standout feature is the real-time preview, enhancing project accuracy. Compared to competitors, it boasts higher resolution and a larger workspace, ideal for both artistic and business applications like custom logos or signage. While the price-performance ratio is strong, occasional minor software bugs could be improved.

Patricia Young (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings with clean edges. Its speed is impressive, handling intricate designs efficiently without sacrificing quality. The software interface is intuitive, making setup straightforward even for novices. Standout features include dual-axis control and variable power settings, which adapt well to different projects. While the price is competitive, long-term maintenance costs could be a consideration. It’s ideal for artistic crafts and small-scale business operations, offering excellent value for its performance capabilities.

Deborah Larsson (verified owner) –

As a hobbyist maker, I’ve found the laser engraver indispensable for creating custom wooden puzzles. The precision of the laser allowed for intricate designs with minimal sanding time, enhancing both efficiency and design complexity. Initially, achieving consistent depth across different wood types was challenging, but testing various settings resolved this issue.

The impact on my workflow has been significant; projects are completed faster, enabling me to take on more orders. Customer feedback has been overwhelmingly positive, praising the puzzles’ durability and aesthetic appeal. Within six months of purchasing the engraver, I saw a noticeable increase in earnings, making it a worthwhile investment that quickly paid for itself through boosted productivity and customer satisfaction.

Friedrich Wang (verified owner) –

“I used the LaserHawk LH3 to create custom metal wall art for my home. It’s so precise and easy, I can’t believe how quickly I got perfect results every time!”

Carlos Wagner –

★★★★★ Excellent Laser Engraver! The engraving quality and precision are top-notch. The machine is intuitive to operate, software user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.