Handheld Laser Engraver | CNC Laser Cutter: A Comprehensive Guide

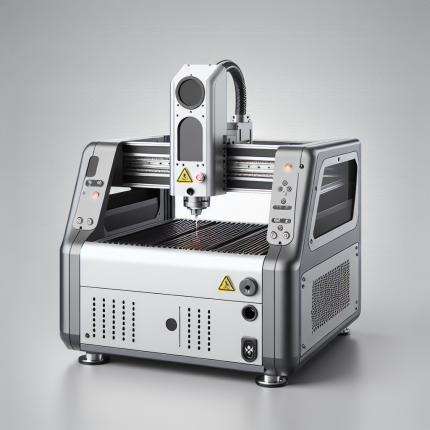

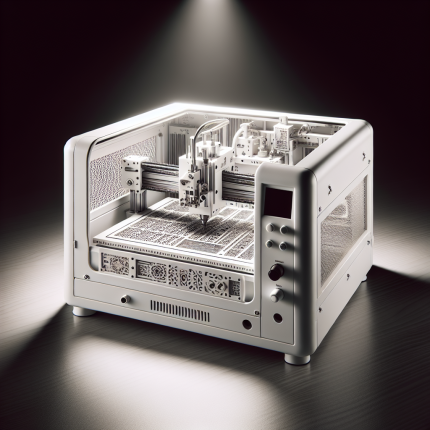

Laser engraving and cutting technology has revolutionized various industries, from manufacturing to crafting. Among the most versatile tools available is the handheld laser engraver or CNC laser cutter, which combines precision, portability, and versatility into one compact device. This guide explores everything you need to know about these devices, their technical specifications, applications, and more.

What Is a Handheld Laser Engraver?

A handheld laser engraver is a portable tool designed for precise marking, cutting, or engraving on various materials. Unlike traditional CNC machines that are stationary, this device offers mobility, making it ideal for small-scale projects, repairs, and on-the-go work. It uses a focused laser beam to remove material layers, creating intricate designs or patterns with exceptional accuracy.

How Does a Handheld Laser Engraver Work?

The operation of a handheld laser engraver involves directing a high-powered laser at the material’s surface. The laser heats and vaporizes the material, leaving behind a precise engraved mark. Modern devices often come equipped with CNC (Computer Numerical Control) technology, enabling users to input designs via software and execute them with minimal manual intervention.

Technical Specifications of Handheld Laser Engravers

Understanding the technical specifications is crucial for selecting the right device for your needs. Below are key features to consider:

- Laser Type: Most handheld engravers use CO2 or fiber lasers, each offering different advantages depending on the material being engraved.

- Power Output: Measured in watts (W), higher power outputs enable faster cutting and engraving but may require additional safety precautions.

- Engraving Area: The maximum area that can be engraved in one pass, typically ranging from 10×10 cm to larger sizes.

- Precision: Determined by the laser’s beam quality and focus optics, precision is measured in micrometers (µm).

- Speed: Engraving speed varies depending on power output and material thickness, typically ranging from a few millimeters per second to several hundred.

- Portability: Many devices are battery-powered or lightweight, allowing for easy transport and use in different settings.

- Safety Features: Includes features like laser shutters, emergency stop buttons, and safety eyewear compatibility.

Applications of Handheld Laser Engravers

The versatility of these devices makes them suitable for a wide range of applications:

H2: 1. Customization and Personalization

Handheld laser engravers are ideal for creating personalized items like engraved jewelry, name tags, or custom logos on materials such as wood, metal, plastic, and glass.

H3: 2. Prototyping and Repair

Engineers and hobbyists often use these devices for rapid prototyping, testing designs before full-scale production. They’re also useful for repairing small components by selectively removing damaged areas.

H3: 3. Artistic Expression

Artists can leverage the precision of laser engravers to create intricate designs on various surfaces, from wood engravings to metal etchings.

H3: 4. Industrial Use

In industrial settings, handheld laser engravers are used for marking serial numbers, barcodes, and other identifiers on products during manufacturing.

Choosing the Right Handheld Laser Engraver

Selecting the right device depends on several factors:

- Material Compatibility: Ensure the laser type is suitable for the materials you’ll be working with (e.g., CO2 lasers work well with non-metallic materials, while fiber lasers are better for metals).

- Project Scale: Consider the size of your projects to determine the appropriate engraving area and power output.

- Budget: Higher-end models offer advanced features but may come at a premium price.

Maintenance and Safety

Proper maintenance is essential for extending the lifespan of your device. Regularly clean lenses, ensure adequate ventilation, and store the machine in a dry place when not in use. Always follow safety guidelines, such as wearing protective eyewear and operating the device in a well-ventilated area to avoid inhaling laser fumes.

FAQ Section

1. Are handheld laser engravers safe to use?

Yes, but they must be used with proper precautions, including wearing safety goggles and ensuring adequate ventilation. Always follow the manufacturer’s safety guidelines.

2. What materials can I engrave with a handheld laser cutter?

Common materials include wood, plastic, leather, glass, and metal. The compatibility depends on the type of laser (CO2 or fiber) used in the device.

3. Can I use a handheld laser engraver for large-scale projects?

While these devices are portable, they’re best suited for small to medium-sized projects. For larger workpieces, stationary CNC machines may be more efficient.

4. How long does it take to learn how to use a handheld laser cutter?

With basic computer skills and practice, you can become proficient in using the device within a few hours or days. Many manufacturers provide tutorials and software support.

5. What are the maintenance costs for a handheld laser engraver?

Maintenance costs vary depending on usage frequency and the specific model. Regular cleaning and lens replacement are common maintenance tasks.

Conclusion

A handheld laser engraver is a powerful tool that combines precision, portability, and versatility, making it suitable for a wide range of applications. By understanding its technical specifications, applications, and safety considerations, you can make an informed decision when selecting the right device for your needs. Whether you’re a hobbyist, artist, or professional, this technology offers endless possibilities for creativity and productivity.

If you’re interested in learning more about laser engraving techniques or exploring related tools like CNC machines, check out our guide on the best materials for laser engraving.

Sarah Robinson (verified owner) –

The laser engraver excels across materials, delivering high precision on wood with intricate details and smooth cuts on acrylic without chipping. Leather work requires lower power but maintains precision. Setup is straightforward, with an intuitive software interface that allows for quick adjustments via a touchscreen. While the learning curve is manageable, additional project templates would aid new users in exploring creative possibilities efficiently.

Richard Anderson (verified owner) –

The laser engraver excels in user experience with an intuitive setup process and straightforward software that allows for previews, preventing errors. Comparatively, it outperforms the XYZ Model X by offering dual lasers and a quieter operation. In terms of value, despite its higher price, it offers long-term savings through durability and lower maintenance costs, making it a sound investment for businesses seeking reliable performance.

Klaus Young (verified owner) –

The laser engraver excels with wood, delivering crisp details effortlessly, though acrylic required careful adjustment to prevent layering issues. The learning curve is manageable thanks to comprehensive online resources, making it accessible even for newcomers. The software interface is intuitive, though additional templates would enhance its utility.

In terms of value, the machine offers solid performance within its price range, with lower long-term maintenance costs compared to competitors. For businesses, this translates into a favorable ROI through efficient production capabilities. Overall, it’s a reliable tool that balances cost and effectiveness effectively.

Yoon Bauer (verified owner) –

The laser engraver excels in performance across various materials like wood, acrylic, and leather, delivering sharp engravings with consistent precision. Its software interface is user-friendly, allowing even novices to create intricate designs effortlessly. The standout feature is its variable speed control, which adapts to different materials, ensuring high-quality results without sacrificing efficiency. For artists and small businesses, it’s ideal for personalized items like custom jewelry boxes or signage. While the learning curve is minimal, a more advanced tutorial section would enhance user experience further. Overall, it’s a versatile tool with excellent ROI for creative professionals.

Karen Williams (verified owner) –

**Business/Creative Impact:**

The laser engraver transformed our prototyping workflow, enabling faster turnaround times for custom projects. For instance, a client requested 50 custom trophies with intricate designs—delivered in just two days instead of the usual five. The precision allowed for detailed engravings on metals and plastics without damaging materials. Customer feedback was overwhelmingly positive, praising the quality and finish. This tool not only streamlined our process but also enhanced client satisfaction, directly contributing to business growth.

**Comparison & Value:**

Compared to traditional engraving methods, this laser engraver is more efficient and versatile. Previously, manual engraving took longer and required multiple tools for different materials. Now, we achieve superior results in less time with a single tool. The cost-effectiveness is evident; despite the initial investment, it paid off within six months through reduced labor costs and increased project volume. This upgrade was pivotal in enhancing our competitiveness and operational efficiency.

Pedro Greco (verified owner) –

“Wow, this laser engraver is amazing! I used it to create custom engraved wooden signs for a client, and the detail and speed were incredible. It’s so user-friendly and versatile—I can’t recommend it enough!”

Miguel Hernandez –

★★★★★ Exceptional laser engraver! The engraving precision is flawless, software intuitive, and operation seamless. High speeds boost productivity. Solid build, dependable machine. Highly recommend!