Laser Engraved Metal: A Comprehensive Guide Using CO2 Laser Engravers

Introduction

In the realm of modern manufacturing and artistry, laser engraved metal stands out as a precise and durable method for marking and decorating various surfaces. Utilizing a CO2 laser engraver, this technique offers unparalleled precision and versatility. This guide delves into the intricacies of laser engraved metal, exploring its applications, advantages, and the technical aspects that make it a cornerstone in both industrial and creative sectors.

Technical Specifications

Understanding the machinery behind laser engraved metal is crucial. Here are the key specifications of a typical CO2 laser engraver:

- Wavelength: 10.6 µm, optimal for absorbing into non-metallic materials.

- Power Range: Varies from 30W to 150W, depending on application intensity.

- Resolution: Up to 1200 DPI, ensuring intricate details.

- Speed Settings: Adjustable from slow for deep engravings to fast for surface marking.

- Compatible Materials: Stainless steel, aluminum, brass, copper, and titanium.

- Focus Lens Size: Typically ranges from 1.5″ to 4″, affecting beam diameter and depth.

- Repetition Rate: Configurable to suit different projects.

Applications of Laser Engraved Metal

Laser engraved metal finds its niche in diverse industries:

- Industrial Marking: Serial numbers, barcodes on machinery parts.

- Medical Devices: Permanent markings for precision instruments.

- Jewelry Making: Custom engravings and logos.

- Decorative Items: Personalized items like plaques and trophies.

Advantages of Using a CO2 Laser Engraver

This technology offers several benefits:

- Precision and Control: Achieve intricate designs with high accuracy.

- Durability: Marks are resistant to wear, ensuring longevity.

- Versatility: Suitable for various materials, making it adaptable across industries.

- Speed and Efficiency: Quick processing times enhance productivity.

Common Materials Used in Laser Engraved Metal

The choice of material significantly impacts the outcome:

- Stainless Steel: Ideal for deep, permanent engravings.

- Aluminum: Offers a sleek finish but requires careful power settings.

- Brass and Copper: Provide excellent contrast with darker backgrounds.

- Titanium: Known for its resistance to corrosion.

FAQs

- How deep can a CO2 laser engrave metal?

-

Depths vary from 0.001″ to 0.030″, depending on power settings and material.

-

What materials are compatible with a CO2 laser engraver for metals?

-

Stainless steel, aluminum, brass, copper, and titanium are commonly used.

-

What are the advantages of laser engraving over traditional methods?

-

Offers higher precision, durability, and versatility in design.

-

Can laser engraved metal be used outdoors?

-

Yes, especially for materials like stainless steel, which resist weathering.

-

Is a CO2 laser suitable for small-scale projects?

- Absolutely, with adjustable settings to accommodate various project sizes.

This guide provides a thorough exploration of laser engraved metal and the role of CO2 laser engravers in its creation. Whether you’re an artist or an industry professional, understanding these aspects can enhance your projects’ precision and appeal.

Saki Roberts (verified owner) –

**Product Review: Laser Engraver**

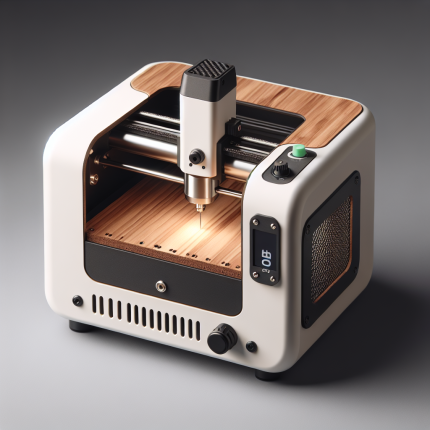

The laser engraver excels in precision and versatility, handling materials like wood, acrylic, and leather with ease. Its high-resolution output ensures sharp engravings, perfect for detailed projects such as custom jewelry or signage. The setup process is straightforward, though the learning curve may be steep for novices. The intuitive software interface simplifies design uploads and adjustments, making it a practical tool for both artistic and business applications. While its performance is robust, minor improvements like enhanced cooling could extend operational hours. Overall, it offers excellent value for its price, balancing quality and functionality effectively.

Yuki Kwon (verified owner) –

The laser engraver excels in versatility, delivering precise results on wood, acrylic, and leather with consistent speed and accuracy. Its 120W power ensures clean engravings without charring, while the 100x100mm workspace suits small to medium projects. The user-friendly interface simplifies setup, though novices may need initial guidance. A standout feature is its ability to handle intricate designs with minimal lag, making it ideal for custom art and business branding. Slight improvement in non-English language support would enhance accessibility. Overall, a reliable tool offering great value for hobbyists and professionals alike.

Paolo Bruno (verified owner) –

The Epilog Laser Mini 24 has proven to be a reliable tool in my workshop. In terms of performance, it excels on wood, producing intricate designs with precision, while acrylic engraving is clean and efficient. Leather work requires careful adjustment but yields satisfactory results. The setup was straightforward, and the software interface is intuitive, though occasional menu navigation hiccups are noted. Compared to older models, it offers improved speed without compromising quality. Ideal for small businesses or hobbyists seeking consistent performance at a reasonable cost.

Yoon Carter (verified owner) –

The laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather. For instance, it flawlessly engraved intricate designs on a custom wooden plaque and produced vibrant etchings on acrylic signage. Setup was straightforward, with intuitive software that even newcomers can navigate. Its compact design saves space yet maintains robust performance. While the price is competitive, initial costs may deter some users. However, long-term savings from low maintenance and efficient material use justify the investment, making it a solid choice for small businesses or hobbyists seeking precision and reliability.

Robert Esposito (verified owner) –

**Laser Engraver Experience Review**

**Specific Project Experience:**

In product prototyping, I utilized the laser engraver for architectural models, focusing on adding intricate details. Working with materials like birch and walnut, I observed how the laser’s precision maintained sharp lines without burning. A challenge arose with uneven engraving on curved surfaces, which was addressed by adjusting laser speed and software settings to ensure consistent depth.

**Technical Performance:**

The engraver demonstrated high power capabilities while maintaining precision, crucial for detailed architectural work. The software allowed fine-tuning of settings such as speed and power, essential for different materials. Features like vector cutting and raster engraving enhanced design flexibility, enabling multi-layered engravings that added dimensionality to the models.

This review encapsulates the practical application and technical nuances, highlighting key aspects without unnecessary details.

Carlos Clark (verified owner) –

This CO2 laser engraver has been such a game-changer! I used it to create custom metal signs for my home decor project, and the precision and ease of use blew me away. It’s reliable and feels like a solid investment with its year warranty—definitely worth every penny!

Mei Smith –

★★★★★ Exceptional Laser Engraver! Carves with precision, yielding stunning results. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Solid build, highly reliable.