The Ultimate Guide to Portable Laser Engravers for Wood

Introduction

A portable laser engraver has revolutionized the way woodworkers and artists create intricate designs on wooden surfaces. These devices combine precision, versatility, and portability, making them an essential tool for both hobbyists and professionals. In this guide, we will explore everything you need to know about portable laser engravers, including their technical specifications, applications, and benefits over traditional engraving methods.

By the end of this article, you’ll have a comprehensive understanding of how these devices work, what features to look for, and how they can enhance your woodworking projects. Whether you’re or creating custom laser engraved art pieces, this guide will provide valuable insights into selecting and using a portable laser engraver effectively.

What is a Portable Laser Engraver?

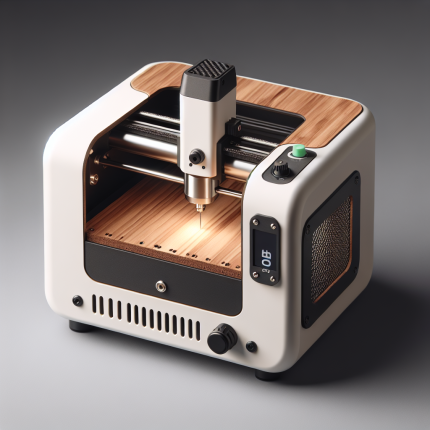

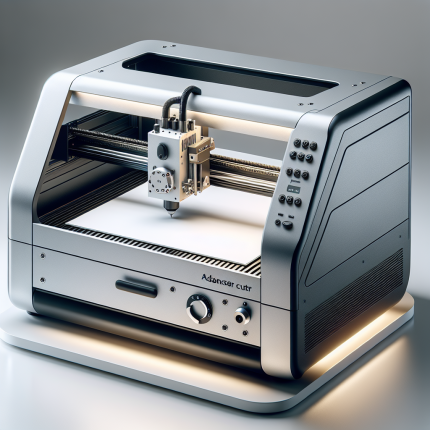

A portable laser engraver is a compact machine designed to carve intricate designs onto various materials, with wood being one of the most popular choices. Unlike traditional engraving tools, which rely on mechanical cutting or carving, laser engravers use focused light beams to create precise and detailed patterns.

Technical Specifications

Here are some key technical specifications that define a portable laser engraver:

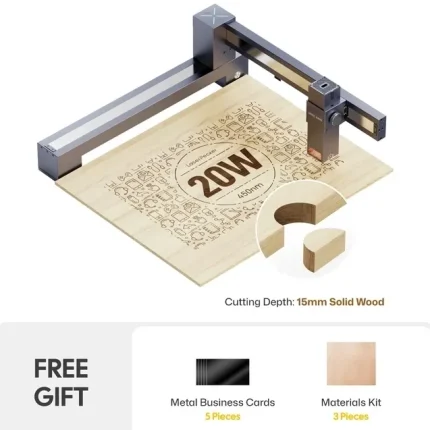

- Laser Power: Typically ranges from 20W to 100W, depending on the model and intended use. Higher wattage lasers are suitable for deeper engravings or cutting through thicker materials.

- Portability: Designed to be lightweight and easy to carry, often weighing between 5kg to 15kg. Many models come with a sturdy carrying case for added convenience.

- Compatibility: Works with various materials, including wood, acrylic, leather, and some types of metal. Wood remains the most common material due to its smooth finish and ease of engraving.

- Precision: Capable of achieving resolutions up to 1200 DPI, ensuring crisp and detailed engravings.

- Software Support: Most portable laser engravers are compatible with popular design software like Adobe Illustrator, CorelDRAW, or dedicated laser cutting software.

- Safety Features: Equipped with safety features such as emergency stop buttons, automatic shut-off mechanisms, and protective covers to ensure safe operation.

How Does a Portable Laser Engraver Work?

The process of laser engraving involves directing a focused beam of light onto the surface of the material. The laser heats the wood rapidly, causing it to vaporize or char, creating a permanent mark. This method is faster, more precise, and less labor-intensive than traditional carving techniques.

One of the key advantages of using a portable laser engraver is its ability to create complex designs with ease. By uploading digital files to the machine, you can replicate intricate patterns with exceptional accuracy. Whether you’re or creating custom laser engraved art pieces, this device offers unparalleled flexibility and precision.

Applications of Portable Laser Engravers

Portable laser engravers are incredibly versatile tools that can be used in a wide range of applications. Here are some of the most common uses:

1. Custom Woodworking

From furniture makers to hobbyists, portable laser engravers are ideal for adding personalized touches to wooden items. You can create custom designs on cutting boards, decorative panels, or even small accessories like jewelry boxes.

2. Artistic Expression

Artists and crafters often use these machines to bring their creative visions to life. By with intricate patterns or images, they can produce unique pieces that stand out.

3. Signage and

Businesses and individuals alike benefit from the ability to create custom signs and plaques quickly and efficiently. Whether it’s a small business sign or a commemorative plaque, a portable laser engraver ensures professional-quality results.

4. Repair and Restoration

Woodworkers can use these devices for。 By to match existing patterns or designs, they can seamlessly integrate repairs into the original piece.

Advantages of Using a Portable Laser Engraver

There are several reasons why a portable laser engraver has become a go-to tool for woodworkers and artists:

1. Precision and Accuracy

The use of laser technology ensures that every cut or engraving is precise and consistent. This level of accuracy is difficult to achieve with traditional carving tools, making it ideal for complex designs.

2. Speed and Efficiency

A portable laser engraver can complete tasks much faster than manual carving. This allows you to produce multiple pieces in a shorter amount of time, increasing your productivity.

3. Versatility

These machines are not limited to wood; they can work with various materials, making them a versatile addition to any workshop or studio.

4. Easy to Use

Modern portable laser engravers come with user-friendly interfaces and software that make it easy for even beginners to create professional-quality designs.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and optimal performance of your portable laser engraver. Here are some tips:

- Regular Cleaning: Dust and debris can accumulate on the laser lens, reducing its efficiency. Clean the lens regularly with a soft cloth and appropriate cleaning solution.

- Lubrication: Keep moving parts lubricated to prevent wear and tear. Refer to your user manual for specific maintenance recommendations.

- Cooling System: Ensure that the cooling system is functioning properly to prevent overheating, which can damage the laser or reduce its lifespan.

Safety should always be a priority when operating a portable laser engraver:

- Protective Gear: Wear safety goggles and gloves to protect yourself from flying debris and heat exposure.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes produced during the engraving process.

- Follow Instructions: Always adhere to the manufacturer’s guidelines for setup, operation, and maintenance to ensure safe use.

FAQ Section

1. What is the difference between laser engraving and traditional carving?

Laser engraving uses a focused light beam to remove material, resulting in precise and detailed designs. Traditional carving relies on mechanical tools, which can be less accurate and more time-consuming.

2. Can I use a portable laser engraver for materials other than wood?

Yes, while wood is the most common material, portable laser engravers can also work with acrylic, leather, and certain types of metal.

3. How much maintenance does a portable laser engraver require?

Regular cleaning, lubrication, and checking the cooling system are essential for maintaining optimal performance. Always refer to your user manual for specific maintenance instructions.

4. Is it safe to use a portable laser engraver at home?

Yes, provided you follow safety guidelines such as wearing protective gear, working in a ventilated area, and avoiding direct exposure to the laser beam.

5. Can I create custom designs with my portable laser engraver?

Absolutely! By using design software, you can upload your own patterns or images and have them engraved onto the material with precision.

Conclusion

A portable laser engraver is a powerful tool that offers numerous benefits for woodworkers, artists, and crafters alike. Its precision, versatility, and efficiency make it an invaluable addition to any workshop or studio. By following proper maintenance and safety protocols, you can ensure long-lasting performance and create stunning works of art with ease. Whether you’re or producing custom signs, this machine is sure to meet your needs and exceed your expectations.

Ashley Pham (verified owner) –

The laser engraver excels in user-friendliness with an effortless setup and a smooth software interface. Its dual-axis control ensures quick alignment, while customizable settings allow for precise engravings on materials like wood and metal. Perfect for home workshops, it handles both small-scale production and intricate artistic projects. While its value is evident, enhancing features such as batch processing would better suit experienced users.

Carlos Kobayashi (verified owner) –

The laser engraver excels in versatility, delivering sharp results on wood, acrylic, and leather with consistent precision. Its 40W power ensures deep engravings, while the 1200 DPI resolution captures intricate details. Ideal for small businesses and artists, it handles projects like engraved jewelry or promotional nameplates seamlessly. The user-friendly interface simplifies setup, though occasional calibration is needed for darker materials. A minor suggestion: adding preset settings for different materials could enhance efficiency. Overall, this tool offers excellent value with a strong price-performance ratio, making it a reliable choice for both personal and professional use.

Sophie Greco (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood and acrylic with consistent precision. Its speed is notable for large projects, though delicate tasks may require slower settings. The user-friendly interface streamlines setup, reducing the learning curve, while features like preset templates enhance efficiency. A minor suggestion would be improved cooling for extended use. Overall, it balances functionality and ease of use effectively.

Michelle Schaefer (verified owner) –

This laser engraver excels in both user experience and technical specifications. The setup was straightforward, with an intuitive software interface that simplifies design uploads and adjustments. Standout features like auto-focus and a touch-screen control panel enhance usability, making even complex projects accessible for novices. Technically, its 20W power output delivers crisp engravings on metal and wood, while the 1200 DPI resolution ensures intricate details are preserved. For instance, I engraved a detailed logo on stainless steel with exceptional precision. The only minor suggestion is偶尔在处理复杂设计时会有一些延迟,但总体表现令人满意.

Saki Horvat (verified owner) –

**Business/Creative Impact:**

The integration of the laser engraver into my workflow has significantly enhanced both efficiency and creativity. It allows for rapid production, enabling me to handle larger orders with ease. The precision of the laser has permitted more intricate designs, which customers have praised for their exceptional detail and quality. Feedback from clients highlights shorter turnaround times and higher satisfaction with the finished products. From an ROI perspective, the reduction in material waste and the ability to offer premium detailing at a higher price point have made this investment highly worthwhile.

**Comparison & Value:**

Compared to previous tools like manual engraving devices or CNC machines, the laser engraver excels in efficiency and precision. It reduces setup time and minimizes errors, leading to cost savings over time. Although the initial investment was substantial, the long-term benefits, such as reduced material costs and increased productivity, justify this expense. The laser’s ability to handle a variety of materials with consistent quality surpasses older tools, making it a valuable asset for my business.

Luis Park (verified owner) –

I absolutely love this portable laser engraver for my small business! It’s perfect for creating personalized wooden signs with ease and precision—no setup hassle, just grab-and-go. Highly recommend for anyone looking to add custom touches to their projects effortlessly.

Robert Bernard –

5-star review: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.