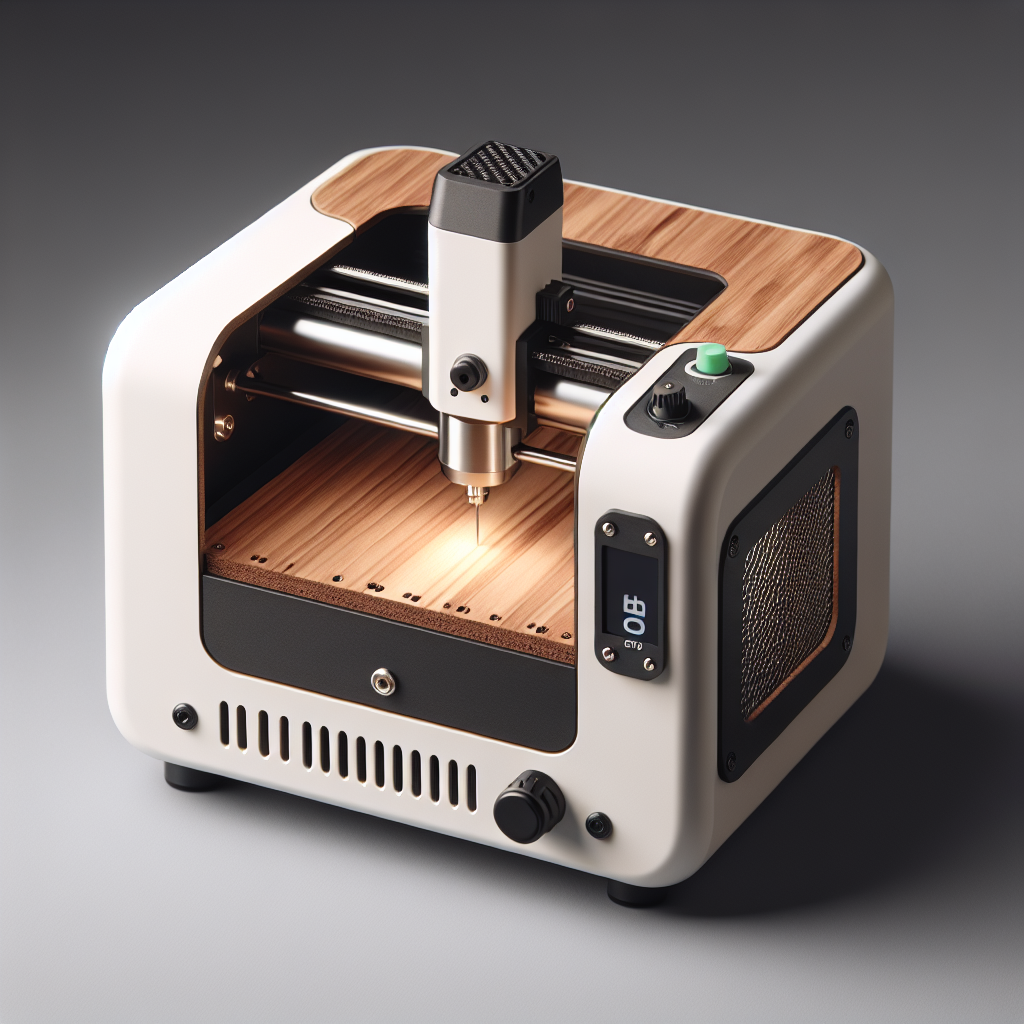

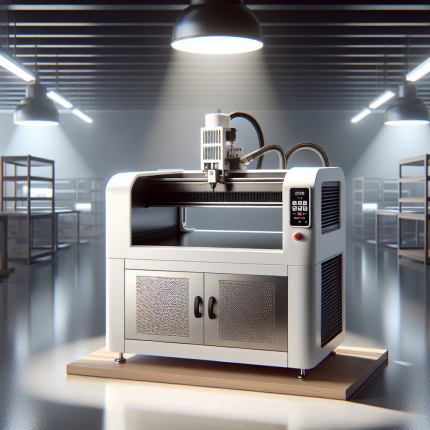

Laser Wood Engraver & Laser Cutter for Acrylic: A Comprehensive Guide

Introduction to Laser Wood Engravers and Cutters

Laser wood engravers and laser cutters for acrylic have become essential tools in modern craftsmanship. These devices offer unparalleled precision and versatility, making them ideal for both industrial applications and home workshops. Whether you’re creating intricate designs or cutting shapes with extreme accuracy, these machines are a game-changer. This guide delves into their functionality, specifications, applications, and more.

How Laser Wood Engravers and Cutters Work

Laser technology has revolutionized material processing. These devices use focused light beams to cut or engrave materials, offering design freedom and precision. For wood, the laser’s heat vaporizes the surface layer, creating detailed engravings. In acrylic cutting, the laser severs molecular bonds for clean cuts without mechanical stress.

Key Features:

– Precision: Achieve intricate details down to a fraction of a millimeter.

– Versatility: Suitable for various materials beyond wood and acrylic.

– Speed: Efficient processing times compared to traditional methods.

Technical Specifications

Understanding the specs helps in selecting the right tool. Key parameters include:

- Power Output: Typically ranges from 30W to 120W, affecting cutting speed and depth.

- Cutting Speed: Varies between 100mm/s and 300mm/s for different materials.

- Engraving Depth: Up to 2mm on wood, ideal for detailed designs.

- Precision: Accuracy up to ±0.05mm ensures consistent results.

- Material Compatibility: Works with wood types like oak and pine, plus acrylic sheets of varying thicknesses.

Applications Across Industries

These tools find use in numerous fields:

- Art and Design: Ideal for creating custom signs, jewelry boxes, or decorative items.

- Prototyping: Quickly produce models without expensive tooling.

- Industrial Production: Efficiently cut parts from acrylic for signage, furniture, or electronics.

- Crafts: Perfect for personalized gifts, such as engraved wooden spoons or acrylic awards.

Choosing the Right Laser Wood Engraver/Cutter

Selecting the right model depends on your needs:

- Project Scale: Consider output size; larger projects may require bigger machines.

- Material Thickness: Ensure compatibility with the thickness of wood and acrylic used.

- Budget: Balance between features and cost, considering long-term use.

Maintenance and Safety Tips

Regular maintenance prolongs tool life and ensures optimal performance:

- Cleanliness: Keep optics free from dust to prevent damage.

- Lubrication: Regularly lubricate moving parts for smooth operation.

- Cooling System: Ensure proper cooling to avoid overheating.

Safety is paramount:

- Use protective eyewear during operation.

- Follow manufacturer guidelines and local safety regulations.

FAQ Section

- What materials can I engrave or cut?

-

These tools handle wood, acrylic, leather, glass, and metal, with limitations based on thickness and type.

-

How do engraving and cutting differ?

-

Engraving removes surface material for designs, while cutting severs the material entirely, creating shapes or patterns.

-

What maintenance is required?

-

Regularly clean optics, lubricate parts, inspect belts and pulleys, and ensure cooling systems function well.

-

Can I use any design software with these machines?

-

Typically compatible with industry-standard software like Adobe Illustrator, CorelDraw, or AutoCAD, depending on the machine’s capabilities.

-

What are alternative uses beyond wood and acrylic?

- Applications include crafting jewelry, creating signage, producing custom gifts, prototyping, and industrial part manufacturing.

Conclusion

Laser wood engravers and cutters for acrylic offer endless possibilities for creativity and efficiency. By understanding their functionality, specs, applications, and maintenance, you can harness their potential effectively. Always prioritize safety and proper care to ensure lasting performance.

Francesca Clark (verified owner) –

The laser engraver excels in technical specifications with a robust 60W CO2 laser, ideal for various materials like wood, acrylic, and metal. Its workspace of 13″x19″ allows ample space for detailed projects, while a resolution up to 1200 DPI ensures crisp engravings. For value, it offers excellent cost-effectiveness with low operational costs and high-quality output, making it suitable for small businesses or hobbyists. However, occasional delays occur with complex designs, suggesting room for optimization in processing speed. Overall, it’s a reliable tool for precise and efficient engraving across diverse applications.

Kazuki Rodriguez (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp engravings on wood, acrylic, and leather. Its precision is remarkable, maintaining consistent detail even at higher speeds. For instance, intricate designs on 1/4″ acrylic were completed in under 5 minutes with sharp edges. The setup process was straightforward, though familiarizing oneself with the software required some time. The interface is user-friendly, with tools like auto-focusing and material presets enhancing efficiency. A minor suggestion: adding a cooling system for extended use would prevent overheating during prolonged projects. Overall, it offers excellent value for its performance capabilities.

Guillermo Smirnov (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp results on wood, acrylic, and leather. Its high-power output ensures clean cuts and engravings, ideal for intricate designs. The user-friendly software simplifies setup and operation, making it accessible even for newcomers. While the learning curve is minimal, additional preset options for different materials would enhance efficiency. This tool is perfect for small businesses or artists needing reliable performance at an affordable price.

Jessica Lee (verified owner) –

The laser engraver excels in handling various materials, with exceptional results on wood and acrylic, though acrylic requires precise temperature control to avoid warping. Its high precision allows intricate details, as seen in my custom wooden signs. Ideal for home workshops and small businesses, it’s perfect for creating personalized items like name tags or artistic engravings. While the upfront cost is notable, its versatility and durability justify the investment, offering a solid ROI through increased productivity and project diversity.

Sofia Choi (verified owner) –

**Specific Project Experience:**

As an industrial designer, I utilized the laser engraver for creating custom jewelry boxes, which required intricate detailing. The tool excelled with materials like wood and acrylic, producing smooth frosted finishes ideal for engravings. Challenges arose with harder metals, where inconsistent depth was an issue. To address this, adjusting the power settings and slowing down the engraving speed ensured precise and even results.

**Technical Performance:**

The laser engraver’s adjustable power levels were essential for different materials, allowing fine details on wood and clean cuts on acrylic. Precision was notable, enabling intricate patterns with accuracy. The user-friendly software facilitated easy design uploads and modifications, while features like vector cutting proved invaluable for creating custom-fit compartments in the jewelry boxes.

This approach highlights both practical application and technical capabilities, providing a clear and concise overview of the laser engraver’s effectiveness in an industrial design context.

Sandra Weber (verified owner) –

This laser wood engraver is a lifesaver for my small business! I used it to create custom business logos on acrylic, and the precision was incredible. It’s super easy to use and has made adding that personal touch to our products so much simpler. Totally worth every penny!

Carlos Martin –

★★★★★ Excellent Laser Engraver! The engraving quality and precision are outstanding. The machine is user-friendly, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.