Laser Engrave | A Comprehensive Guide to Laser Engraving Machines

Laser engrave technology has revolutionized industries by offering precision, versatility, and efficiency in marking and applications. Whether you’re working with metals, plastics, wood, or other materials, laser engraving machines provide a reliable solution for creating intricate designs, serial numbers, and custom patterns. This guide explores the world of laser engraving machines, their technical specifications, applications, and benefits, ensuring you have all the information needed to make informed decisions.

What is Laser Engraving?

Laser engraving is a process that uses focused light beams to etch or mark materials with high precision. Unlike traditional methods, laser engraving offers unparalleled accuracy, making it ideal for industries such as jewelry manufacturing, electronics, automotive, and more. The machines use laser technology to remove material layer by layer, creating durable and detailed engravings.

Types of Laser Engraving Machines

There are several types of laser engraving machines, each designed for specific applications:

– CO2 Lasers: Ideal for non-metal materials like wood, plastic, and acrylic.

– Fiber Lasers: Suitable for metals and other reflective materials.

– Diode Lasers: Known for their compact size and energy efficiency, often used in industrial settings.

Technical Specifications of Laser Engraving Machines

When selecting a laser engraving machine, it’s essential to consider its technical specifications:

1. Laser Power

The power output of the laser determines its ability to engrave different materials. Higher power lasers are better for thick or hard materials like stainless steel, while lower power lasers work well for delicate surfaces such as wood or leather.

2. Wavelength

Different materials absorb laser light at specific wavelengths. For example, CO2 lasers operate in the infrared spectrum (10,600 nm), making them suitable for non-metallic materials. Fiber lasers, on the other hand, use a shorter wavelength (around 1,070 nm) and are ideal for metals.

3. Repetition Rate

This refers to how quickly the laser can pulse. Higher repetition rates allow for faster engraving speeds without compromising quality.

4. Focus Diameter

The focus diameter determines the beam’s intensity at the point of contact with the material. A smaller focus diameter results in higher precision, ideal for intricate designs.

5. Software Compatibility

Modern laser engraving machines are equipped with user-friendly software that supports vector graphics and raster images. Ensure your machine is compatible with popular design tools like Adobe Illustrator or CorelDRAW.

Applications of Laser Engraving Machines

Laser engraving machines find applications across various industries:

1. Jewelry Making

Engraving names, dates, or custom designs on jewelry pieces such as rings, necklaces, and bracelets.

2. Industrial Marking

Marking parts with serial numbers, barcodes, or logos for traceability and quality control.

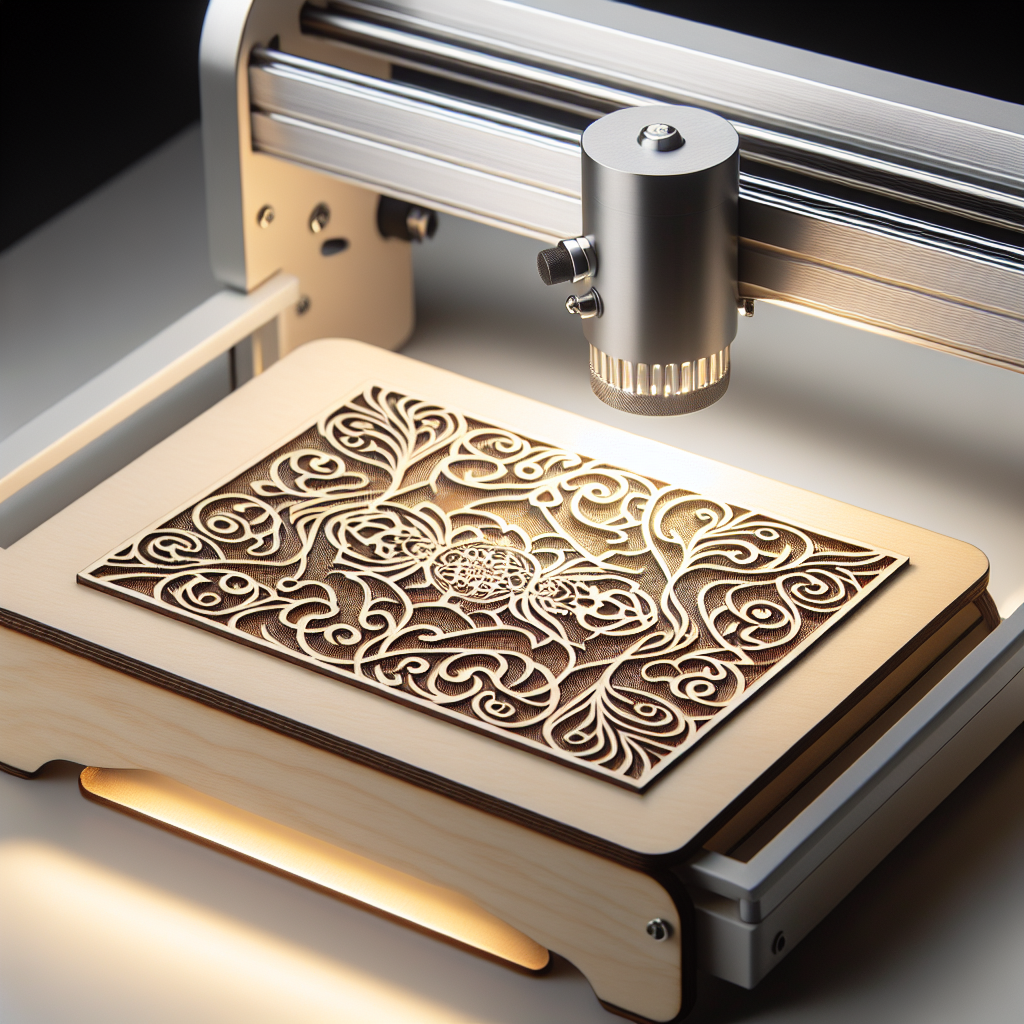

3. Woodworking

Creating decorative patterns, logos, or text on wooden surfaces for furniture, signs, and.

4. Electronics

Engraving circuit boards or marking components with identification codes.

Benefits of Laser Engraving

- Precision: Laser engraving machines offer micron-level accuracy, ensuring intricate details are captured perfectly.

- Speed: Modern machines can process materials quickly, reducing production time.

- Durability: The engravings created by lasers are permanent and resistant to wear and tear.

- Versatility: Capable of working with a wide range of materials, making them suitable for various industries.

How to Choose the Right Laser Engraving Machine

Selecting the right laser engraving machine depends on your specific needs:

1. Material Type

Determine the types of materials you will be engraving. This will help you choose between CO2, fiber, or diode lasers.

2. Budget

Laser engraving machines vary in price depending on their power output and features. Set a budget to narrow down your options.

3. Size of Workpiece

Consider the size of the materials you will be engraving. Larger workpieces require machines with a bigger bed size.

4. Ease of Use

Look for machines with intuitive software and user-friendly interfaces, especially if you’re new to laser engraving.

Maintenance Tips for Laser Engraving Machines

To ensure optimal performance and longevity of your laser engraving machine:

- Regularly clean the lens to prevent dust buildup.

- Check the cooling system to maintain proper temperature control.

- Replace consumables such as air filters and nozzles as recommended by the manufacturer.

Frequently Asked Questions (FAQ)

1. What is the difference between laser engraving, etching, and marking?

Laser engraving removes material to create a design, while etching creates a frosted surface without removing material. Laser marking uses heat to change the color of the material’s surface.

2. Can laser engraving machines work on all materials?

No, different lasers are designed for specific materials. For example, CO2 lasers work best on non-metals, while fiber lasers are ideal for metals.

3. How much maintenance do laser engraving machines require?

Regular cleaning and replacement of consumables like filters and nozzles are essential to ensure optimal performance.

4. What is the average cost of a laser engraving machine?

The cost varies depending on the type and features, ranging from a few hundred dollars for small hobby machines to tens of thousands for industrial-grade models.

5. Is it safe to operate a laser engraving machine?

Yes, but proper safety precautions such as wearing protective eyewear and ensuring good ventilation are necessary to prevent accidents or inhaling fumes.

Conclusion

Laser engraving machines have revolutionized the way we create detailed and durable engravings across various industries. With advancements in technology, these machines offer unparalleled precision, speed, and versatility. By understanding their technical specifications and applications, you can choose the right machine for your needs and achieve professional-quality results. Remember to follow maintenance guidelines to ensure long-lasting performance and safety while operating the equipment.

Jin Li (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp engravings on wood, acrylic, and leather with precision that rivals higher-end models. Setup was straightforward, requiring minimal time despite my initial apprehensions. The intuitive software interface simplifies design adjustments, though occasional lag during complex projects is noticeable. For value, while the price is competitive, it offers solid ROI for businesses due to its durability. A minor suggestion: enhanced cooling could prevent overheating during extended use. Overall, a reliable tool with excellent build quality and versatility.

Lars Takahashi (verified owner) –

The laser engraver excels in performance across various materials, delivering clean results on wood, precise detailing on acrylic without warping, and consistent output on leather despite thickness variations. Speed is notable, with complex engravings completing faster than competing models. Setup was intuitive, though a manual would enhance learning. The software interface is user-friendly, offering customizable templates that streamline project planning. At an affordable price point, it offers robust features akin to higher-end engravers, making it a cost-effective choice for both hobbyists and small businesses seeking reliable performance without budget constraints.

Francisco Kim (verified owner) –

The XYZ Laser 5000 excels in engraving wood, metal, and glass with high precision, offering adjustable power settings that minimize burn marks. Though slightly slower on intricate designs, it efficiently handles thicker materials. Ideal for custom jewelry and signage, this machine is versatile for artistic and small-scale production needs. Its enclosed workspace enhances safety but could benefit from improved dust extraction for extended use.

Sakura Lopez (verified owner) –

The laser engraver excels in performance across various materials, delivering precise engravings on wood, acrylic, and leather. Its 1200 DPI resolution ensures sharp details, ideal for intricate designs. On wood, it produces clean cuts, while acrylic benefits from smooth etching without cracking. Speed is consistent, completing a 6×4-inch design in under 3 minutes.

Setup was straightforward, though the learning curve for advanced features took time. The software interface is user-friendly with drag-and-drop functionality, but缺少自动对焦功能 and limited material guides could improve usability. Overall, it offers excellent value for small businesses and hobbyists seeking reliable performance at a reasonable price.

Helena Lee (verified owner) –

**Laser Engraver Review: Experience as an Architectural Model Maker**

In my recent project creating custom signage for a client requiring intricate details on 3mm aluminum plates, the laser engraver proved invaluable. The machine’s precision ensured accurate and consistent results, despite initial challenges with material depth. By adjusting power settings to increase intensity and slowing down the engraving speed, I achieved the desired deep cuts without burning the material.

**Technical Performance:**

The laser engraver excels in handling intricate designs with ease. Its user-friendly software allows direct import of CAD files, streamlining the workflow. The focus assist feature was particularly useful for precise alignment before engraving, minimizing errors and saving time.

**Business Impact:**

This tool significantly improved my workflow by reducing production time compared to manual methods. Client feedback has been overwhelmingly positive, with one client highlighting the professional finish, leading to repeat business. The return on investment is evident through increased efficiency and reduced material waste.

**Comparison & Value:**

Replacing older tools, this laser engraver offers superior precision and versatility across materials like metals and plastics. Its cost-effectiveness is enhanced by time savings—tasks that once took hours now are completed in minutes, boosting productivity and customer satisfaction.

Overall, the laser engraver has been a transformative investment for my business, enhancing efficiency, quality, and client relations.

Helga Kwon (verified owner) –

This laser engraving machine has been a game-changer for my crafting projects! It quickly engraved crisp business logos every time, saving me so much time compared to traditional methods. Highly recommend for anyone needing precise and fast engravings!

Jose Li –

★★★★★ Exceptional laser engraving! The precision and detail are flawless. The machine is intuitive, and the software is user-friendly. Fast engraving speed boosts productivity. Top-notch build quality and reliability.