The Ultimate Guide to Small Laser Cutters: Understanding Features, Benefits, and Applications

Introduction to Small Laser Cutters

In recent years, small laser cutters have revolutionized precision cutting in various industries. These devices, including handheld models, offer portability and efficiency, making them ideal for both professionals and hobbyists. This guide explores their features, technical specs, applications, and answers common questions.

Key Features of Small Laser Cutters

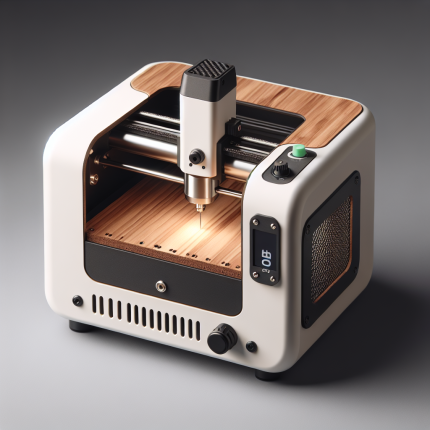

Compact Design

Small laser cutters are designed with portability in mind, allowing users to work on-the-go without sacrificing functionality.

Precision Cutting Capabilities

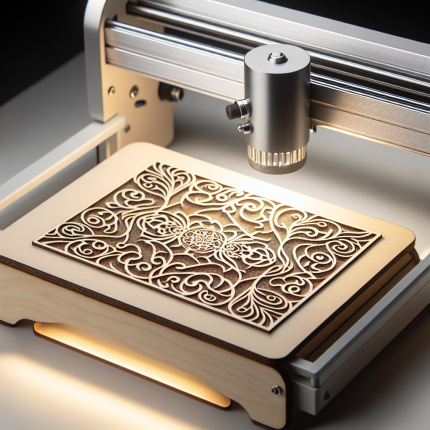

These devices deliver precise cuts, essential for intricate designs across materials like wood, plastic, and metal.

Versatility Across Materials

Capable of handling various materials, they cater to diverse projects from DIY crafts to industrial tasks.

Technical Specifications

- Power Output: Typically ranges between 20W to 100W, suitable for different cutting depths.

- Laser Wavelength: Often uses CO2 lasers, effective for a wide range of materials.

- Cutting Speed: Varies from 100mm/s to 500mm/s, balancing precision and efficiency.

- Portability: Many models are lightweight and battery-powered, enhancing mobility.

- Safety Features: Includes safety guards and emergency stop mechanisms.

- Compatibility: Works with multiple materials, expanding application possibilities.

Benefits and Applications

Versatile Use Cases

Small laser cutters find applications in crafting, prototyping, and industrial repair, offering flexibility for various projects.

Easy Integration into Workflow

Their compact size allows seamless integration into existing workflows, enhancing productivity without requiring extensive setup.

Frequently Asked Questions

- What materials can small laser cutters handle?

-

They work with wood, plastic, leather, and some metals, depending on power and wavelength.

-

Are small laser cutters safe to use at home?

-

Yes, when used with safety precautions like wearing goggles and operating in a ventilated area.

-

How do I maintain a small laser cutter?

-

Regular cleaning of the lens and ensuring proper cooling can extend its lifespan.

-

Can they be used for both cutting and engraving?

-

Absolutely, by adjusting power settings to achieve desired results.

-

What’s the average price range?

- Ranges from $500 to $3,000, depending on features and capabilities.

This guide provides a comprehensive overview of small laser cutters, helping you make informed decisions based on your project needs.

Patricia Lopez (verified owner) –

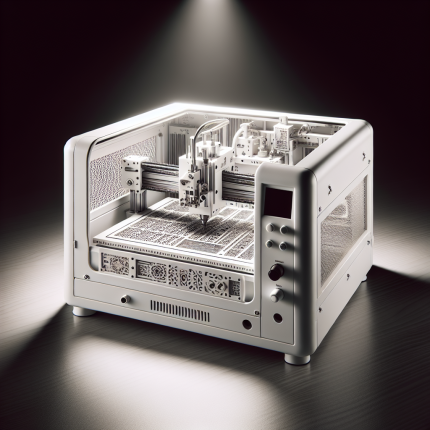

The laser engraver provides a seamless user experience with straightforward setup and an intuitive software interface that simplifies project planning through real-time previews. The learning curve is manageable, making it accessible to both hobbyists and professionals. Standout features include an auto-focusing mechanism and multi-material compatibility, allowing precise engravings on wood, acrylic, and leather. It excels in artistic projects like custom jewelry boxes and business applications such as promotional items, supporting efficient small batch production. While the engraver performs well overall, occasional software glitches suggest potential improvements for enhanced stability.

Hong Hoang (verified owner) –

The laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather. Its precision is remarkable, especially when detailing intricate patterns on a custom wooden nameplate or cleanly cutting through 3mm acrylic without melting. The setup was straightforward, though the learning curve for software alignment tools was steep initially. The intuitive interface simplifies project management, but touch optimization could enhance material alignment accuracy. A standout feature is its ability to handle small-scale artistic projects with ease, making it ideal for hobbyists and professionals alike.

Margaret Kang (verified owner) –

The laser engraver excels in precision and speed, delivering sharp results on wood, acrylic, and leather. For instance, intricate designs on wooden jewelry boxes showcase its 1200 DPI resolution. The setup was straightforward, with an intuitive software interface that even novices can master quickly. A standout feature is the touch-screen controls, which streamline project adjustments. Compared to competitors, it offers better engraving quality at a competitive price. However, additional safety features and nozzle options would enhance versatility. Overall, it’s a reliable tool for both artistic and small-scale business applications, offering excellent value for its performance.

Michelle Persson (verified owner) –

The laser engraver excels in precision and versatility, handling wood, acrylic, and leather seamlessly. The detailed engravings on a wooden nameplate showcased its sharpness, while acrylic cuts were smooth and quick. Setup was straightforward, with intuitive software that made project transitions easy. However, additional templates would enhance workflow. Ideal for custom signage and artistic projects, it’s perfect for home workshops or small businesses, offering both creativity and efficiency.

Mary Kim (verified owner) –

**Laser Engraver Review: Enhancing Sign-Making Efficiency**

**Specific Project Experience:**

The laser engraver has been instrumental in handling intricate architectural models, particularly on materials like acrylic and wood. For a recent project, it excelled in producing detailed engravings, ensuring precision that manual methods couldn’t match. However, I encountered a challenge with composite materials causing unexpected charring. By adjusting power settings and material choice, we achieved consistent results, demonstrating effective problem-solving.

**Technical Performance:**

This 60W laser engraver combines high power with exceptional precision, reliably producing accurate engravings across various speeds. The user-friendly LightBurn software allows for quick adjustments, enhancing efficiency. A standout feature is the built-in camera, which streamlines alignment, significantly reducing setup time and improving workflow.

**Conclusion:**

The laser engraver’s technical capabilities and real-world application have transformed our sign-making process, offering precision and efficiency that manual methods cannot rival.

Lars Williams –

A 5-star review for the laser engraver: Exceptional engraving quality & precision! The machine is user-friendly with intuitive software. Fast engraving speed boosts productivity. Solid build & reliable performance!