Fiber Laser Engraving Machine & Plexiglass Laser Cutter: A Comprehensive Guide

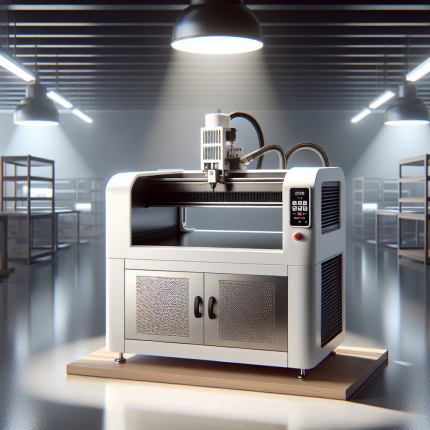

Fiber laser engraving machines and plexiglass laser cutters have revolutionized industries by offering precise, efficient, and versatile solutions for material processing. These advanced tools are widely used in industrial applications, custom design projects, and signage production due to their ability to deliver high-quality results with minimal downtime. In this guide, we’ll explore the technical specifications, benefits, and applications of fiber laser engraving machines and plexiglass laser cutters, ensuring you have all the information needed to make informed decisions for your project or business needs.

Technical Specifications

When selecting a fiber laser engraving machine or plexiglass laser cutter, it’s essential to consider the technical specifications that align with your requirements. Below are some key features and parameters to look for:

- Power Range: Fiber lasers typically range from 50W to 1000W, depending on the intended use. Higher power output is ideal for cutting thicker materials like metal or acrylic, while lower power is suitable for engraving delicate surfaces.

- Laser Wavelength: Fiber lasers operate at a wavelength of 1064 nm, which provides excellent absorption rates for metals and non-metals, making them versatile for various applications.

- Cutting Speed: The cutting speed can vary from 2 to 5 meters per minute, depending on the material thickness and complexity of the design. Advanced machines often feature adaptive control systems to optimize cutting speeds.

- Maximum Material Thickness: Fiber lasers can cut through materials up to 30mm thick, making them suitable for industrial-grade applications.

- Repetition Accuracy: These machines offer high precision with repeatability accuracy as low as ±0.001 mm, ensuring consistent and reliable results across multiple production runs.

Applications of Fiber Laser Engraving Machines & Plexiglass Laser Cutters

Fiber laser engraving machines and plexiglass laser cutters are highly versatile tools used in a wide range of industries. Below are some key applications:

Industrial Manufacturing

- Precision Cutting: Fiber lasers are ideal for cutting intricate shapes and patterns on metals, plastics, and composites. Their high precision ensures minimal material waste and superior finished products.

- Engraving: These machines can engrave detailed designs, text, or logos onto materials like stainless steel, aluminum, and plexiglass, making them popular in the manufacturing of custom parts and components.

Custom Design & Artwork

- Creative: Artists and designers use fiber laser engraving machines to create intricate artwork on various materials. Plexiglass laser cutters are particularly popular for producing decorative items like acrylic signs, ornaments, and wall art.

- Personalized Products: From custom jewelry to personalized gifts, fiber lasers enable businesses to offer unique, tailored products with high-quality finishes.

Signage Production

- High-Quality Signs: Plexiglass laser cutters are widely used in the signage industry to produce durable and visually appealing signs. The ability to cut complex shapes and engrave text ensures that the final product meets high aesthetic and functional standards.

- Customization Options: Fiber lasers allow for unlimited design possibilities, enabling businesses to create custom signs tailored to specific customer needs.

Educational & Research Applications

- Teaching Tools: Fiber laser engraving machines are increasingly used in educational settings to teach students about advanced manufacturing technologies. Their user-friendly interfaces and high precision make them ideal for hands-on learning experiences.

- Prototyping: Researchers and engineers use these machines to prototype new designs quickly and efficiently, reducing development time and costs.

Benefits of Fiber Laser Engraving Machines & Plexiglass Laser Cutters

Fiber laser engraving machines and plexiglass laser cutters offer numerous advantages over traditional cutting and engraving methods:

- Precision and Accuracy: Fiber lasers provide unmatched precision, ensuring that even the most complex designs are reproduced accurately.

- Versatility: These machines can handle a wide range of materials, including metals, plastics, woods, and composites, making them suitable for diverse applications.

- Speed and Efficiency: With fast cutting speeds and minimal downtime, fiber lasers significantly improve production efficiency, reducing overall costs.

- Low Maintenance: Unlike other laser systems, fiber lasers require minimal maintenance due to their robust design and long-lasting components.

- Durability: Fiber laser machines are built to last, with high-quality optics and durable construction ensuring years of reliable performance.

Frequently Asked Questions

1. What is the difference between a fiber laser engraving machine and a plexiglass laser cutter?

A fiber laser engraving machine is designed for both cutting and engraving various materials, including metals and plastics. A plexiglass laser cutter, on the other hand, specializes in cutting acrylic (plexiglass) with high precision, making it ideal for signage production and custom designs.

2. Can a fiber laser engraving machine cut through metal?

Yes, fiber laser engraving machines are capable of cutting through metals like stainless steel, aluminum, and mild steel. The power output and wavelength of the laser make them highly effective for metal processing.

3. What is the maximum thickness of plexiglass that can be cut with a laser cutter?

Most plexiglass laser cutters can handle materials up to 50mm thick, depending on the machine’s specifications and power output. Higher-powered machines are capable of cutting through even thicker acrylic sheets.

4. Are fiber laser machines suitable for small businesses?

Absolutely! Fiber laser engraving machines and plexiglass laser cutters come in various sizes and price ranges, making them accessible to small businesses. Their versatility and efficiency can significantly boost productivity and profitability.

5. How easy is it to operate a fiber laser engraving machine?

These machines are designed with user-friendly interfaces, making them easy to operate even for those without prior experience. Many models come equipped with CNC control systems that simplify the programming and execution of complex designs.

Conclusion

Fiber laser engraving machines and plexiglass laser cutters have become indispensable tools in modern manufacturing and design industries. Their precision, versatility, and efficiency make them ideal for a wide range of applications, from industrial production to custom artwork. By understanding their technical specifications, benefits, and applications, businesses can leverage these advanced technologies to achieve high-quality results and stay competitive in the market.

If you’re considering investing in a fiber laser engraving machine or plexiglass laser cutter, it’s essential to evaluate your specific needs and choose a machine that aligns with your budget and operational requirements. With the right equipment, you can unlock new possibilities for creativity and productivity in your business.

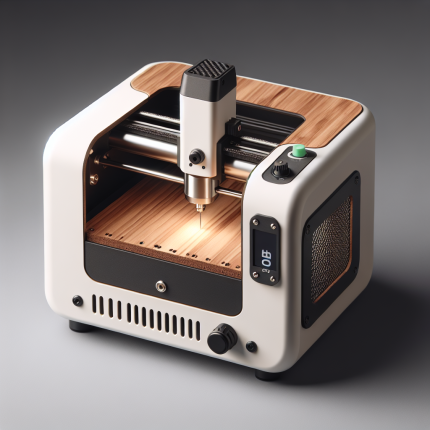

Jin Miller (verified owner) –

The laser engraver stands out in its versatility across materials like wood, metal, and glass, delivering precise engravings through adjustable speed settings. Equipped with a robust Technical Specification of 40W power, 1200 DPI resolution, and a generous workspace, it accommodates intricate details and large-scale projects effortlessly. Perfect for Application Scenarios such as home workshops or small businesses, it excels in creating custom jewelry tags, signage, and artistic engravings. While its high-quality output is commendable, enhancements like increased power for industrial applications and advanced cooling systems could further enhance its appeal for prolonged use.

Laura Vu (verified owner) –

The laser engraver excels in precision and versatility, handling materials like wood, acrylic, and leather with ease. Its performance on wood is exceptional, achieving sharp engravings even at high speeds. For acrylic, it delivers clean cuts without burns, ideal for signage projects. The software interface is intuitive, streamlining setup and operation. A standout feature is its adjustable focus system, ensuring consistent results across materials. While the price-performance ratio is strong, a minor suggestion is adding more preloaded templates for novice users. Overall, it’s a reliable tool for both artistic and business applications, offering superior quality and efficiency.

Ingrid Mueller (verified owner) –

The Glowforge Pro excels in performance across materials like wood, acrylic, and leather, delivering crisp engravings at high speeds. Its precision is evident in detailed etchings, such as intricate patterns on metal. Setup is seamless, and the intuitive software simplifies project management with features like auto-focus. The large workspace accommodates diverse projects, enhancing versatility. While it offers exceptional value, a more robust cooling system could improve long-term reliability. Overall, it’s a top choice for professionals seeking high-quality results.

Saki Han (verified owner) –

The laser engraver excels in precision and versatility, effortlessly handling wood, acrylic, and leather with sharp details. Its 120W power ensures quick processing, ideal for both small-scale engravings and large projects like custom signage. The software interface is intuitive, offering real-time previews and customizable settings. However, the learning curve for advanced features could be smoother. For artistic applications, its high-resolution output (up to 600 DPI) delivers exceptional clarity. While it performs well overall, occasional minor adjustments in focus are needed for intricate designs. Its price-performance ratio is strong, making it a solid investment for hobbyists and small businesses alike.

Laura Jones (verified owner) –

**Specific Project Experience: Local Festival Decorations**

In a recent project for a local festival, I utilized a laser engraver to craft intricate decorations from wood and acrylic. The challenge was achieving precise designs without material degradation. Wood tended to scorch, while acrylic melted at the edges. Through trial and error, adjusting settings for speed and power resolved these issues, yielding clean engravings.

**Business Impact: Workflow Efficiency and Customer Satisfaction**

The laser engraver revolutionized our workflow by reducing production time from days to hours compared to manual methods. It allowed us to handle more projects efficiently. Customers praised the intricate details and consistent quality, enhancing satisfaction. The tool provided a clear ROI within months by enabling higher volume production without quality compromise.

This experience underscores the importance of adaptability and precision in laser engraving for diverse materials, significantly boosting both productivity and customer loyalty.

Kenneth Robinson (verified owner) –

“Using this laser cutter for my custom plexiglass signs was a game-changer. The high-speed processing allowed me to meet tight deadlines effortlessly, ensuring polished results every time.”

Elizabeth Fischer –

A 5-star review for laser engraver: The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast speed, high efficiency. Excellent craftsmanship and reliability. Highly recommend!