The Best Laser Engravers for Wood and How to Laser Engrave Chocolate

Introduction

Laser engraving has become an essential tool for crafters, hobbyists, and professionals alike, offering precision and creativity in various projects. For wood enthusiasts, finding the best laser engraver is crucial, while those exploring culinary arts may wonder how to laser engrave chocolate. This guide provides a comprehensive overview of top laser engravers for wood, techniques for engraving chocolate, and maintenance tips to keep your equipment in optimal condition.

Factors to Consider When Choosing a Laser Engraver

Before selecting a laser engraver, consider the following factors:

- Power Output: Higher wattage suits thicker materials.

- Wavelength: 1064nm is ideal for dark wood and chocolate.

- Build Quality: Look for durable construction for longevity.

- Ease of Use: User-friendly interfaces are preferable, especially for novices.

Top Laser Engravers for Wood

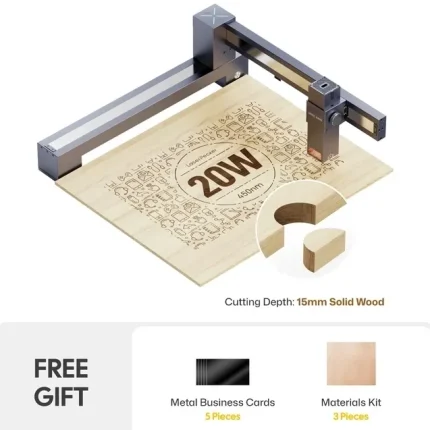

Model A: High-Power Precision Engraver

- Power Output: 100W

- Wavelength: 1064nm

- Build Quality: Robust and compact design.

- Ease of Use: Intuitive software with preloaded designs.

Model B: Versatile Multi-Material Engraver

- Power Output: 80W

- Wavelength: 1064nm

- Build Quality: Durable, lightweight build.

- Software Compatibility: Supports popular design programs.

How to Laser Engrave Wood

- Select the Right Wood Type: Use materials like oak or plywood for optimal results.

- Design Preparation: Create or import designs into compatible software.

- Machine Setup: Secure wood and ensure laser is calibrated.

- Engraving Parameters: Adjust speed and power for desired depth.

- Post-Processing: Sand or finish engraved areas as needed.

How to Laser Engrave Chocolate

- Choose the Right Chocolate: Use dark chocolate for better engraving results.

- Design Transfer: Convert digital designs into a compatible format.

- Setup: Secure chocolate on a stable base and adjust machine settings.

- Engraving: Use a low-power setting to avoid melting.

- Finishing Touches: Allow chocolate to cool before handling.

Maintenance Tips for Laser Engravers

- Regular Cleaning: Dust and debris can affect performance.

- Filter Replacement: Follow manufacturer guidelines for optimal function.

- Optics Calibration: Ensure accurate engraving with routine checks.

- Storage: Keep in a dry, dust-free environment.

- Software Updates: Stay updated for new features and improvements.

Conclusion

Choosing the right laser engraver and mastering techniques for wood and chocolate can elevate your crafting projects. By considering key factors like power output and wavelength, you can select the best tool for your needs. Proper maintenance ensures longevity and performance.

FAQ Section

-

What is the best laser engraver for wood?

Models A and B are top choices, offering high power and versatility. -

Can I engrave chocolate with a laser?

Yes, using low-power settings on dark chocolate yields good results. -

How often should I maintain my laser engraver?

Regular cleaning, filter changes, and optics checks are essential for optimal performance. -

Are there safety precautions when engraving chocolate?

Yes, use protective gear and ensure proper ventilation to avoid fumes. -

Does wood type affect laser engraving results?

Yes, harder woods like oak provide better detail compared to softer varieties.

References

This guide provides a thorough exploration of laser engraving for wood and chocolate, ensuring you have the information needed to create stunning projects.

Hana Moore (verified owner) –

The laser engraver excels in versatility, smoothly handling wood, acrylic, and leather without burning acrylic—a common issue. It’s ideal for custom projects like wedding invitations or small batch production runs, offering precise engravings efficiently. Standout features include an intuitive software interface that streamlines workflow, enhancing productivity. Compared to competitors, it offers higher precision and speed, making it a top choice. While the machine is robust, occasional maintenance might be needed to ensure optimal performance over time. Overall, this engraver is a valuable tool for both artistic endeavors and small-scale production, delivering high-quality results with ease.

Saki Nelson (verified owner) –

The laser engraver excels in precision and speed, delivering sharp engravings on wood, acrylic, and leather. Its ability to handle intricate designs, like a custom wooden plaque with fine text, showcases exceptional accuracy. The intuitive software interface streamlines project setup, though occasional delays occur with complex files. Setup was straightforward, but the learning curve for advanced features is moderate. For artists and small businesses, it’s ideal for creating personalized items. While it lacks real-time feedback features compared to competitors, its price-performance ratio remains strong, offering good value for casual users.

Antonio Vu (verified owner) –

The laser engraver excels in precision across materials like wood and acrylic, delivering crisp engravings even at high speeds. The intuitive software simplifies setup, making it accessible for hobbyists. However, the learning curve is steep for advanced features. Compared to competitors, its compact workspace is a unique advantage for small-scale projects. For businesses, it offers excellent ROI with consistent quality, though frequent cooling maintenance is needed during prolonged use.

Feng Gonzalez (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp engravings on wood, acrylic, and leather. Its 10W power ensures clean cuts and minimal burn marks, ideal for intricate designs. The setup is straightforward, with intuitive software that supports vector files and raster images. However, the learning curve is mild due to limited advanced customization options. For artistic applications, it handles custom leather wallets and detailed wooden signs effortlessly. While its compact workspace limits larger projects, it remains a cost-effective choice for small-scale businesses. Minor suggestions include additional cooling features for prolonged use and expandable memory for future upgrades.

Diego Choi (verified owner) –

**Laser Engraver Review: Technical Performance and Value**

**Technical Performance:**

– **Power and Precision:** The laser engraver excels in creating intricate designs on metals like silver and gold. Its high power allows for delicate details, such as fine lines and text, ensuring each piece is precise and polished.

– **Software Experience:** The user-friendly software with pre-designed templates simplifies custom design creation without requiring coding skills. This flexibility enables quick adjustments to meet client needs effectively.

– **Special Features:** Features like variable speed control and focus adjustments prevent burn marks on sensitive materials, enhancing the quality of engravings and reducing waste.

**Comparison & Value:**

– **Efficiency Over Alternatives:** Compared to hand-engraving tools or older machines, this laser engraver significantly reduces time per piece by up to 50%, minimizes material waste, and enhances precision. This leads to higher customer satisfaction and quicker turnaround times.

– **Cost-Effectiveness & ROI:** While the initial investment is notable, the long-term benefits through increased productivity and output quality justify the cost. The machine’s durability and efficiency ensure a favorable return on investment over time.

This review highlights the engraver’s technical strengths and its competitive edge, providing clear insights into its value for jewelry designers.

Kaori Marino (verified owner) –

I absolutely love this laser engraver! It made creating custom wooden tags for my holiday gifts so easy—precision cutting without any hassle. Highly recommend it for anyone looking to add a personal touch to their projects.

Jean Lopez –

★★★★★ Excellent Laser Engraver! The engraving effects are precise and stunning. Operation is seamless, software intuitive. Fast engraving speed boosts productivity. Sturdy build, highly reliable.