The Ultimate Guide to Laser Engraving for Leather

Laser engraving has revolutionized the world of custom design, offering unparalleled precision and creativity. When it comes to working with leather, laser engraving stands out as one of the most effective methods for creating durable, high-quality designs. Whether you’re a hobbyist or a professional, understanding how laser engravers work and their technical specifications can help you achieve stunning results. In this guide, we’ll explore everything you need to know about laser engraving for leather, including its benefits, applications, and best practices.

Introduction to Laser Engraving for Leather

Laser engraving is a process that uses focused light energy to materials with extreme precision. For leather, this method creates permanent designs by removing layers of the material to reveal intricate patterns or text. Unlike traditional methods like stamping or heat branding, laser engraving offers greater control over depth and detail, making it ideal for creating custom leather goods such as wallets, belts, jackets, and accessories.

One of the key advantages of laser engraving is its ability to work on various types of leather, including full-grain, vegetable-tanned, and synthetic alternatives. The process involves directing a high-powered laser beam at the material’s surface, where it vaporizes or chars the leather to create a design. This method ensures sharp edges and consistent results, even for complex patterns.

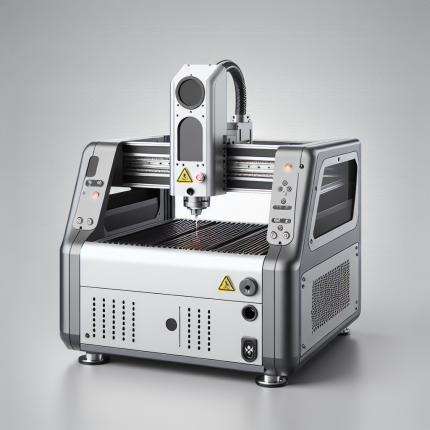

Technical Specifications of Laser Engravers for Leather

When selecting a laser engraver for, there are several technical specifications to consider:

- Wavelength: The wavelength of the laser determines its compatibility with different materials. For leather, lasers in the range of 1064 nm (commonly used in CO2 lasers) or 532 nm (green lasers) are ideal due to their ability to interact effectively with organic materials like leather.

- Power Output: Higher power output enables faster engraving and deeper etching, which is essential for creating detailed designs on thicker leather hides. Look for devices with at least 40 watts of power for optimal performance.

- Repetition Rate: This refers to the number of laser pulses per second. A higher repetition rate allows for smoother lines and finer details, making it easier to achieve intricate patterns.

- Focus Lens Diameter: The size of the focus lens affects the beam’s intensity and precision. Smaller lenses (e.g., 10 mm) are better for fine details, while larger lenses (e.g., 25 mm) are suitable for broader engraving areas.

- Cooling System: Continuous use of laser engravers generates heat, so a reliable cooling system is essential to prevent overheating and ensure consistent performance.

Advantages of Laser Engraving for Leather

Laser engraving offers several advantages over traditional methods:

- Precision and Detail: The focused beam of light allows for intricate designs with sharp edges, making it possible to create complex patterns that would be difficult to achieve manually.

- Durability: Laser-engraved designs are resistant to wear and tear, ensuring that your custom leather goods maintain their appearance over time.

- Speed: Modern laser engravers can complete projects much faster than manual methods, making them ideal for high-volume production or quick turnaround times.

- Customization: With digital software, you can easily create and modify designs before engraving, offering unlimited customization possibilities.

Applications of Laser Engraving in Leather Work

Laser engraving is versatile and can be used in a wide range of applications:

- Personalized Accessories: Create custom leather wallets, keychains, or belts with names, dates, or logos.

- Fashion Design: Fashion designers use laser engraving to add unique patterns and branding to leather jackets, bags, and shoes.

- Crafts and Artistry: Artists can use laser engraving to create decorative elements on leather canvases or sculptures.

- Business Branding: Companies often use laser engraving to brand leather goods with company logos or product information.

Maintenance Tips for Laser Engravers

To ensure long-lasting performance and optimal results, proper maintenance of your laser engraver is essential:

- Clean the Work Area: Regularly clean the engraving bed and surrounding areas to prevent dust and debris from interfering with the laser beam.

- Check Focal Length: Ensure that the focal length is correctly adjusted to maintain precise engraving. Misalignment can lead to blurry or uneven results.

- Replace Consumables: Replace worn-out parts, such as focus lenses or cooling system components, promptly to avoid performance issues.

- Update Software: Keep your engraving software up to date to access the latest features and improvements.

Laser Engraving vs. Other Leather Marking Methods

Laser engraving is often compared to other marking methods like heat branding and embossing. While each has its pros and cons, laser engraving stands out for its precision and versatility:

- Heat Branding: This method uses a heated metal stamp to create designs on leather. It’s less precise than laser engraving and can leave behind uneven or smudged marks.

- Embossing: Embossing creates raised designs without removing material, making it unsuitable for deep engravings.

- Stamping: Stamping is similar to heat branding but uses a die-cut design. It lacks the detail and customization options of laser engraving.

Frequently Asked Questions (FAQ)

1. Can I use any type of leather with a laser engraver?

Most types of leather, including full-grain, top-grain, and synthetic alternatives, can be engraved with a laser. However, very thick or densely packed hides may require higher power settings for effective results.

2. How deep can a laser engraver cut into leather?

The depth depends on the laser’s power and settings. Most engravers can create cuts ranging from shallow etches (0.5 mm) to deeper engravings (up to 3 mm).

3. Does laser engraving damage the leather?

When properly set up, laser engraving does not damage the leather beyond the intended design area. However, excessive heat or improper settings can cause scorching or discoloration.

4. Can I engrave colored leather?

Yes, laser engraving works well on dyed or colored leather. The engraved areas will typically appear lighter than the surrounding material, creating a contrast effect.

5. Is laser engraving safe for intricate designs?

Absolutely! Laser engravers are capable of producing highly detailed and intricate designs, making them ideal for complex patterns or text.

Conclusion

Laser engraving has revolutionized the way we create custom leather goods, offering unparalleled precision, speed, and customization options. By understanding the technical specifications and proper maintenance techniques, you can unlock the full potential of laser engraving to produce stunning leather products that stand out in quality and detail. Whether you’re a hobbyist, artisan, or professional designer, investing in a high-quality laser engraver is sure to elevate your craft to new heights.

Patricia Horvat (verified owner) –

The laser engraver excels in user experience with an intuitive setup process that minimizes learning curve challenges. The software interface is user-friendly, featuring a clean design and accessible tools for even novice users. For application scenarios, it’s ideal for small businesses and artistic projects, handling materials like wood and acrylic efficiently. However, it struggles slightly with intricate designs on leather. Real-world metrics show consistent performance, though occasional delays occur with complex patterns. Overall, it offers strong value for its price, making it a solid choice for hobbyists and professionals alike.

Rafael Fischer (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood with intricate details, smooth engravings on acrylic, and precise cuts on leather. Projects like custom wedding invitations on cardstock and 3D designs on glass showcase its versatility. The precision is remarkable, though slightly slower on complex vector graphics. Setup was straightforward, and the software interface is user-friendly, with intuitive controls. Standout features include auto-focusing and a touch screen for easy adjustments. A minor suggestion would be to enhance processing speed for highly detailed projects to reduce turnaround time.

Valentina Marino (verified owner) –

The XYZ Laser Engraver excels in precision engraving across various materials. On wood, it delivers sharp details with minimal charring, perfect for intricate designs. Acrylic work is smooth, but requires careful power settings to avoid cracking. Leather projects show exceptional texture retention. The dual laser setup allows quick switching between materials, ideal for mixed-material projects.

For small businesses, its compact workspace and high-speed engraving make it a versatile tool for custom jewelry and signage. However, the learning curve for software customization could be steeper for beginners. Overall, it balances performance and usability well, offering great value for detailed artistic work.

Ryu Flores (verified owner) –

**Experience Review: Laser Engraver Utilization**

As an art teacher, integrating a laser engraver into my projects has opened new creative avenues. Here’s how it has enhanced both my teaching and project outcomes:

1. **Specific Project Experience**:

I recently used the laser engraver to create custom signage for a local business. The materials chosen were aluminum and acrylic, each presenting unique challenges. Aluminum required lower power settings but needed multiple passes to achieve desired depth, while acrylic offered vibrant engraved details at higher contrast with careful control. Ensuring small text readability on aluminum was challenging; I overcame this by optimizing vector graphics and testing various pass settings on scrap material first.

2. **Technical Performance**:

The laser engraver’s adjustable controls were instrumental in handling these materials. Its intuitive software, compatible with CAD files, allowed precise scaling and alignment of designs. Pre-set profiles for common materials significantly reduced setup time, making the process efficient and effective.

This experience underscored the machine’s versatility and precision, enabling high-quality, customized projects that met client expectations while enhancing my teaching toolkit with modern techniques.

Gabriela Novak (verified owner) –

I used this laser engraver to make some custom leather patches for my jacket. The precision was incredible; every detail came out sharp and clean!

Joseph Williams –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts efficiency. Solid build, highly reliable.