Understanding Laser Engravers: A Comprehensive Guide

In the ever-evolving landscape of modern manufacturing and design, laser engravers have emerged as indispensable tools. This guide delves into the world of laser engraving, exploring its significance, types, technical aspects, applications, and more.

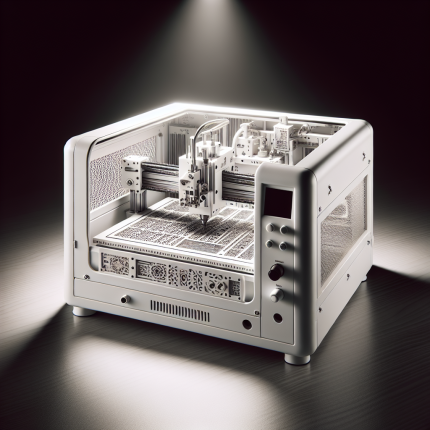

What Are Laser Engravers?

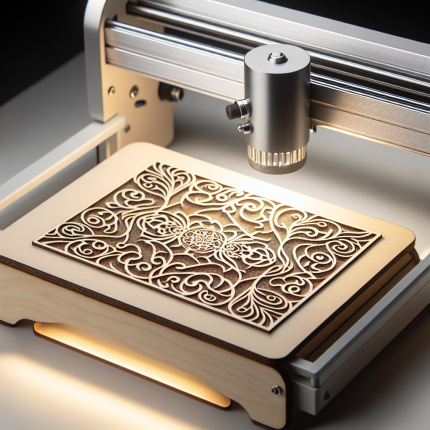

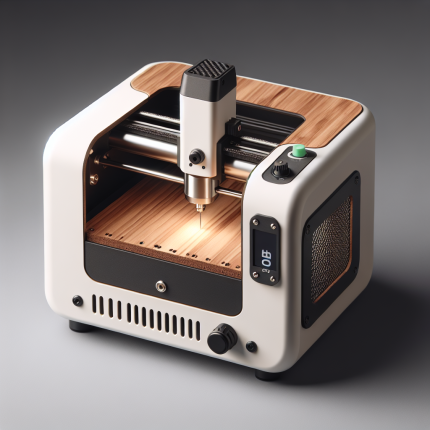

Laser engravers are advanced machines that use high-powered lasers to create precise, permanent markings on various materials. They offer unmatched precision and customization, making them ideal for industries like jewelry, electronics, automotive, and medical devices.

Types of Laser Engravers

- CO2 Lasers: Ideal for non-metallic materials such as wood, plastic, and glass.

- Fiber Lasers: Suitable for metals and alloys, offering high-speed engraving with minimal thermal impact.

- Diode Lasers: Best for marking plastics and composites, known for their compact size and efficiency.

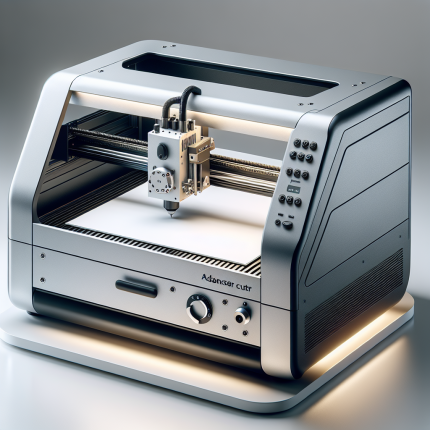

Technical Specifications

- Laser Type: CO2, Fiber, or Diode

- Power Output: Ranges from 10W to 500W, depending on material and application

- Repetition Rate: Varies from low Hz for deep engravings to high kHz for surface marking

- Software Compatibility: CAD/CAM software integration for design input

- Speed: Engraving speeds up to 1000 mm/s, with variable settings based on complexity

- Safety Features: Includes emergency stop buttons and safety shields

Applications of Laser Engravers

Laser engraving finds application in various sectors:

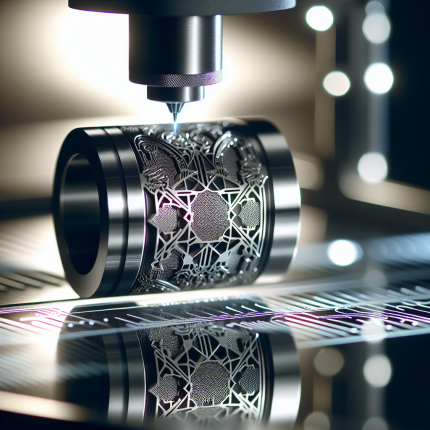

- Jewelry Making: Custom designs on precious metals.

- Electronics: Serial numbers and logos on components.

- Medical Devices: Detailed markings on surgical instruments.

Advantages of Laser Engraving

- Precision: Microscopic accuracy for intricate designs.

- Durability: Marks resistant to wear and tear.

- Customization: Personalized engravings for unique products.

- Speed: Efficient processing, reducing production time.

Limitations of Laser Engravers

- Material Constraints: Not suitable for all materials, especially thick metals or high reflectivity ones.

- Cost Considerations: High initial investment and maintenance costs.

- Setup Complexity: Requires skilled operators for optimal results.

Maintenance Tips

- Laser Head Cleaning: Regular cleaning to maintain performance.

- Focus Lens Inspection: Ensure clear lens for accurate engraving.

- Cooling Systems Check: Prevent overheating by maintaining cooling units.

FAQ Section

Q: What’s the difference between laser engraving and marking?

– Engraving removes material layers, creating deep marks. Marking discolors the surface without removing material.

Q: Which materials are suitable for laser engraving?

– Metals, plastics, wood, glass, leather, and composites.

Q: How often should I service my laser engraver?

– Regular maintenance every 50-100 hours of use, including cleaning and inspecting parts.

Q: What happens if power settings are too high?

– Overpower can damage the material or shorten laser life.

Q: Can laser engravers be used in jewelry making?

– Yes, they create intricate designs on various metals and gemstones.

Conclusion

Laser engravers revolutionize industries by offering precise, durable markings. Despite some limitations, their versatility and efficiency make them invaluable. As technology advances, their applications will continue to expand, solidifying their role in modern manufacturing.

Karen Wilson (verified owner) –

The laser engraver excels in precision across various materials. On wood, it delivers sharp engravings with minimal burn, ideal for custom nameplates. Acrylic projects, such as vibrant logos, show excellent clarity without cracking. Leather engraving produces clean lines, perfect for personalized items. The 120W power setting ensures fast processing, while the 600 DPI resolution guarantees detailed outcomes. However, delicate materials require careful power adjustment to avoid over-engraving. Overall, it balances speed and precision, making it versatile for artistic and business applications.

Johanna Kim (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering crisp details at high speeds. Its precision ensures clean cuts on acrylic and intricate designs on leather. The setup is straightforward, though the learning curve requires some time to master advanced software features. For small businesses, it’s ideal for creating custom signs or jewelry engravings. While its compact workspace limits larger projects, the price-performance ratio remains strong, making it a solid choice for hobbyists and professionals alike.

Sandra Garcia (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp engravings on wood, acrylic, and leather with ease. The software interface is user-friendly, though new users may need time to master advanced settings. Its compact workspace suits small-scale projects like custom name tags or decorative signs. While it offers excellent value for hobbyists, businesses may benefit more from its consistent performance. Minor updates to improve noise reduction would enhance long-term usability. Overall, it’s a reliable tool for artists and crafters seeking quality at an affordable price.

Sophie Young (verified owner) –

This laser engraver excels in performance across various materials like wood and acrylic, delivering sharp engravings with consistent precision. The user-friendly interface streamlines setup and operation, ideal for both novices and professionals. Technical specs, including high resolution and ample workspace, ensure versatile applications. While it offers excellent value for its price, additional dust collection features would enhance long-term usability.

Paolo King (verified owner) –

**Laser Engraver Experience: Custom Trophies & Technical Precision**

As a hobbyist maker, my experience with the laser engraver has been transformative, particularly in crafting custom trophies and awards. The machine excels at precision, delivering sharp text and clean lines on materials like acrylic, which is ideal for these projects. I’ve used it to create personalized sports trophies, where the engraved details stand out vividly against the material.

One challenge was managing uneven surfaces, especially with thicker acrylic, which sometimes warped during engraving. To address this, I pre-sanded the areas and adjusted the laser’s power settings for slower, more controlled cutting. This approach minimized warping and ensured consistent results.

The laser’s 40W power provides ample strength without overburning, and its software is intuitive yet flexible, allowing me to tweak designs for optimal engraving. Features like vector cutting and multi-speed modes have been invaluable for achieving precise cuts and detailed engravings.

This tool has significantly streamlined my workflow, reducing the time spent on finishing touches. Customers have praised the quality of the trophies, enhancing my reputation as a skilled craftsman. Overall, the laser engraver has been a cost-effective investment, offering excellent value and efficiency for custom projects.

Pierre Anderson –

5-Star Review: This laser engraver delivers stunning results with exceptional precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Top-notch build quality & reliability. Highly recommend!