Laser Acrylic Cutter & Metal Laser Engraving Machine: A Comprehensive Guide

Laser technology has revolutionized the manufacturing and design industries, offering precision and efficiency that traditional methods simply cannot match. Among the most versatile tools in this field are laser acrylic cutters and metal laser engraving machines. These devices are designed to handle a wide range of materials with ease, from delicate acrylic sheets to durable metals like stainless steel and aluminum. Whether you’re working on small-scale projects or large industrial applications, these machines provide unparalleled accuracy and adaptability.

This guide will explore the features, benefits, and technical specifications of laser acrylic cutters and metal laser engraving machines. We’ll also discuss their applications across various industries and address common questions to help you make an informed decision. Let’s dive in.

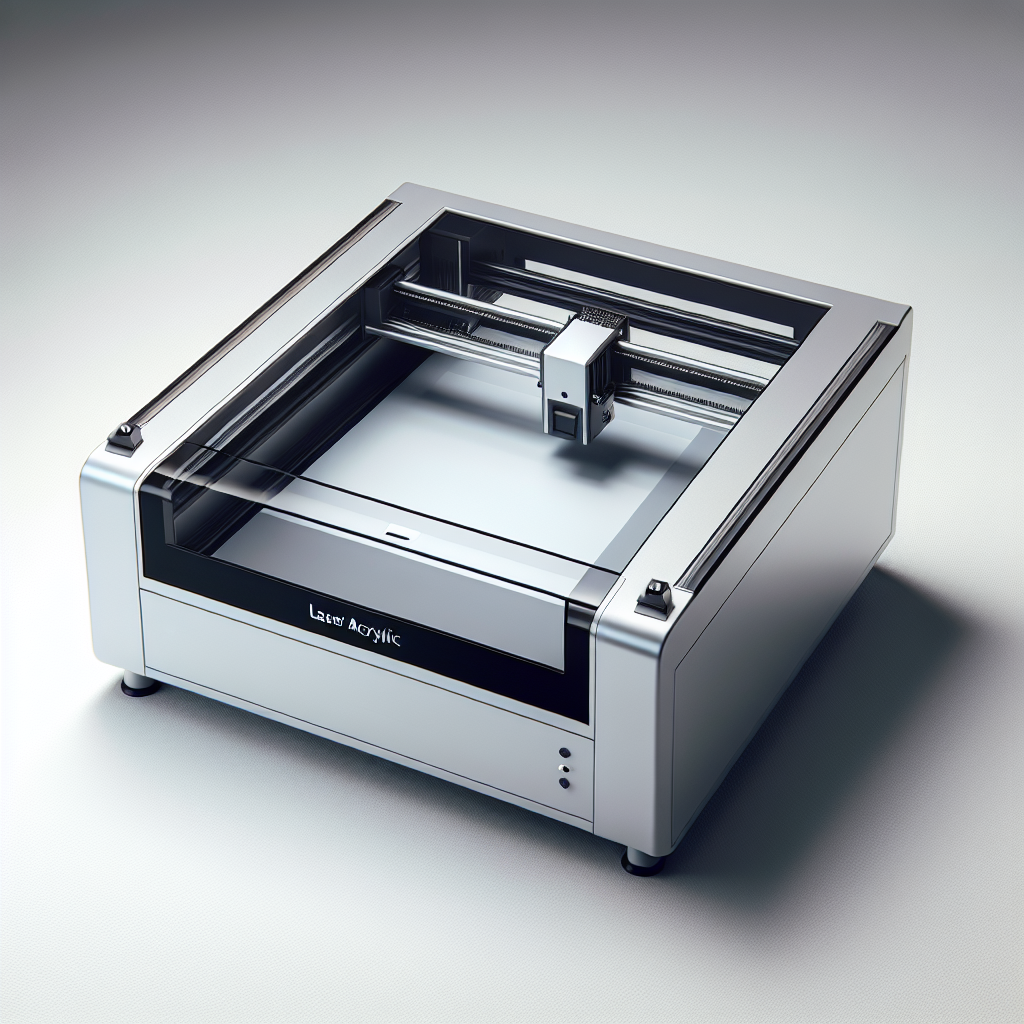

Overview of Laser Acrylic Cutters

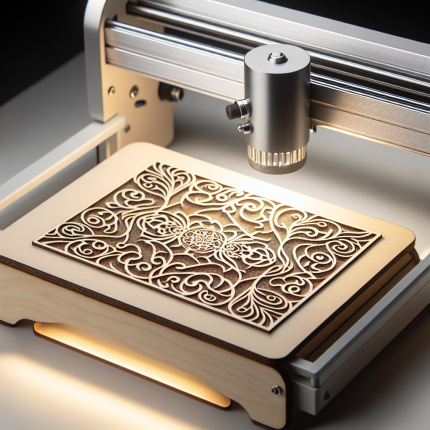

A laser acrylic cutter is a specialized machine designed for cutting and intricate designs on acrylic materials. Unlike traditional cutting methods, which often require physical contact with the material, laser cutters use focused light beams to achieve precise cuts without causing damage or warping. This makes them ideal for creating detailed patterns, logos, and custom shapes in acrylic sheets.

Key Features of Laser Acrylic Cutters

- Precision Cutting: Capable of achieving tight tolerances, making it suitable for intricate designs.

- Versatility: Compatible with various thicknesses of acrylic, from thin sheets to thicker blocks.

- Speed: Efficient processing times, reducing production lead times.

- Minimal Material Waste: Laser cutting minimizes waste compared to traditional methods.

Technical Specifications of Laser Acrylic Cutters

Understanding the technical specifications is crucial when selecting a laser acrylic cutter. Below are some key parameters to consider:

- Laser Power Output: Typically ranges from 20W to 100W, depending on the intended use and material thickness. Higher power output allows for faster cutting of thicker materials.

- Cutting Speed: Varies based on laser power and material type but can reach up to several meters per minute.

- Maximum Material Thickness: Usually ranges from 3mm to 50mm, depending on the machine’s specifications.

- Work Area Size: Commonly available in sizes such as 1200mm x 600mm or larger, accommodating various project requirements.

- Resolution and Accuracy: High-resolution systems ensure precise cuts with minimal deviation from design specifications.

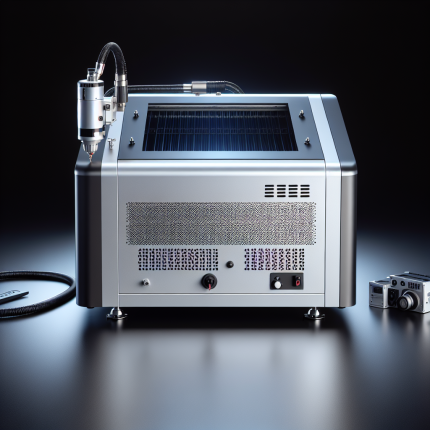

Overview of Metal Laser Engraving Machines

Metal laser engraving machines are designed for precision engraving on metal surfaces, creating permanent markings such as logos, serial numbers, or custom designs. These machines use a high-powered laser beam to etch the surface without causing warping or discoloration. They are widely used in industries like jewelry making, automotive manufacturing, and industrial signage production.

Key Features of Metal Laser Engraving Machines

- High Precision: Capable of engraving intricate details with exceptional accuracy.

- Material Compatibility: Suitable for a wide range of metals, including stainless steel, aluminum, brass, and titanium.

- Speed and Efficiency: Fast processing times, making them ideal for high-volume production environments.

- Durability: Built to withstand heavy use in industrial settings, ensuring long-term performance.

Technical Specifications of Metal Laser Engraving Machines

When choosing a metal laser engraving machine, it’s essential to evaluate its technical capabilities. Here are some critical specifications:

- Laser Wavelength: Typically operates at 1064nm for optimal engraving on metals.

- Repetition Rate: Higher repetition rates enable faster processing times.

- Engraving Speed: Ranges from a few hundred millimeters per second to several meters per second, depending on the machine’s power and configuration.

- Maximum Engraving Depth: Varies based on laser power but can reach up to 2mm for certain metals.

- Work Area Size: Available in various sizes, including compact models for small-scale projects and larger units for industrial use.

Applications of Laser Acrylic Cutters & Metal Laser Engraving Machines

Both laser acrylic cutters and metal laser engraving machines find applications across multiple industries due to their versatility and precision.

Applications of Laser Acrylic Cutters

- Signage Production: Creating custom signs, letters, and decorative elements for businesses and public spaces.

- Furniture Design: Adding intricate designs or patterns to acrylic furniture components.

- Model Making: Prototyping and creating scale models with precise details.

- Artistic Projects: Enabling artists to work with acrylic materials for sculptures, wall art, and other creative endeavors.

Applications of Metal Laser Engraving Machines

- Jewelry Making: Engraving names, symbols, or patterns on jewelry pieces.

- Automotive Industry: Marking parts with serial numbers, logos, or other identifiers.

- Medical Equipment: Engraving medical devices for traceability and identification purposes.

- Industrial Signage: Creating durable signs and plaques for industrial facilities.

Choosing the Right Machine: Key Considerations

When selecting a laser acrylic cutter or metal laser engraving machine, consider the following factors:

- Material Compatibility: Ensure the machine is designed to work with your specific materials.

- Project Requirements: Assess the scale and complexity of your projects to determine the appropriate power output and work area size.

- Budget: Compare prices and features to find a machine that offers the best value for your needs.

- Maintenance and Support: Look for machines with reliable customer support and easy maintenance options.

FAQ Section

1. Can laser acrylic cutters be used for other materials besides acrylic?

Yes, many laser acrylic cutters are capable of cutting other non-metallic materials such as wood, plastic, and fabric. However, their primary design is optimized for acrylic.

2. What is the difference between a laser acrylic cutter and a metal laser engraving machine?

Laser acrylic cutters are designed for cutting and on acrylic materials, while metal laser engraving machines specialize in engraving intricate designs on metal surfaces.

3. Do these machines require special training to operate?

While basic operation can be learned quickly, advanced features may require some training or familiarity with CAD software.

4. How much maintenance do these machines typically require?

Regular maintenance tasks include cleaning the laser optics and ensuring proper cooling systems are functioning. Frequent use may necessitate more frequent checks.

5. Can I switch between acrylic cutting and metal engraving on the same machine?

Generally, no. Most machines are designed for one specific task—either cutting acrylic or engraving metal. However, some advanced models may offer multi-functional capabilities.

Conclusion

Laser acrylic cutters and metal laser engraving machines are indispensable tools for modern manufacturing and design processes. Their precision, versatility, and efficiency make them ideal for a wide range of applications across various industries. By understanding their technical specifications and applications, you can choose the right machine to meet your project needs effectively.

Lisa Gonzalez (verified owner) –

The laser engraver excels in performance across materials, delivering precise engravings on wood with intricate details and handling large acrylic sheets efficiently, though slower on thicker acrylics. Setup was straightforward, with an intuitive software interface featuring drag-and-drop ease. Standout features include auto-focus and real-time preview, enhancing efficiency. Ideal for home workshops or small businesses, it suits custom projects like signs or leather goods. While versatile and user-friendly, a more robust cooling system and advanced documentation would be beneficial.

Daniel Martinez (verified owner) –

The laser engraver excels across various materials, offering crisp engravings on wood, precise cuts on acrylic without cracking, and clean lines on leather despite its texture. Its high precision allows intricate designs, such as custom jewelry, while maintaining speed for efficient large-scale projects like acrylic signs.

Ideal in small workshops or home studios with proper ventilation, it suits a range of applications from personalized items to artistic wood engravings. The value is strong, balancing cost with capability, though minor improvements like enhanced dust collection and more user tutorials could further enhance its appeal.

Hyun Thompson (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather, delivering crisp engravings with minimal setup. Its speed is impressive for intricate designs, completing projects efficiently without compromising quality. For instance, it flawlessly engraved a detailed nameplate on acrylic within minutes. The intuitive software interface simplifies design adjustments, making it accessible even to newcomers. However, occasional overheating during prolonged use could be addressed with improved cooling features. Overall, its versatility and ease of use make it ideal for both artistic and small-scale business applications, offering excellent value for its performance capabilities.

Kenji Nakamura (verified owner) –

The laser engraver excels in precision engraving on wood, acrylic, and leather, delivering crisp details even at high speeds. For instance,雕刻 a custom wooden nameplate required minimal adjustments for optimal depth control. The software interface is user-friendly, with intuitive tools that simplify project setup, though occasional delays occur during complex file uploads. Standout features include the automatic focus system, which ensures consistent engraving quality, and real-time preview capabilities that reduce trial-and-error waste. While it performs exceptionally well in artistic projects, a minor suggestion is to improve file import compatibility for broader design flexibility.

Margot Kobayashi (verified owner) –

**Art Teacher’s Experience with Laser Engraver**

**Specific Project Experience:**

As an art teacher, I utilized the laser engraver for a project involving intricate patterns on wooden bowls. The challenge was achieving deep engravings without burning the wood. By carefully adjusting power settings and using clamps to prevent warping, we managed to create detailed designs that enhanced the bowls’ aesthetic appeal.

**Technical Performance:**

The 40W laser provided sufficient power for precise engraving. Using Cricut Design Space, I uploaded vector files for clean outlines and raster engravings, ensuring detailed patterns without damage. The software’s user-friendly interface facilitated easy adjustments, allowing me to control heat distribution effectively.

This combination of careful project management and technical expertise allowed us to produce high-quality, artistic wooden bowls that were both durable and visually striking.

Rafael Nilsson (verified owner) –

“I absolutely love this laser cutter! Creating custom business logos for my clients is a breeze now—it’s precise, super easy to use, and has transformed my projects!”

Joseph Miller –

五星好评: This laser engraver delivers exceptional engraving precision and quality. The operation is smooth, software intuitive. Fast speeds boost productivity. Top-notch build quality & reliability!