Mini Laser Engraver | Laser Acrylic Cutter: A Comprehensive Guide

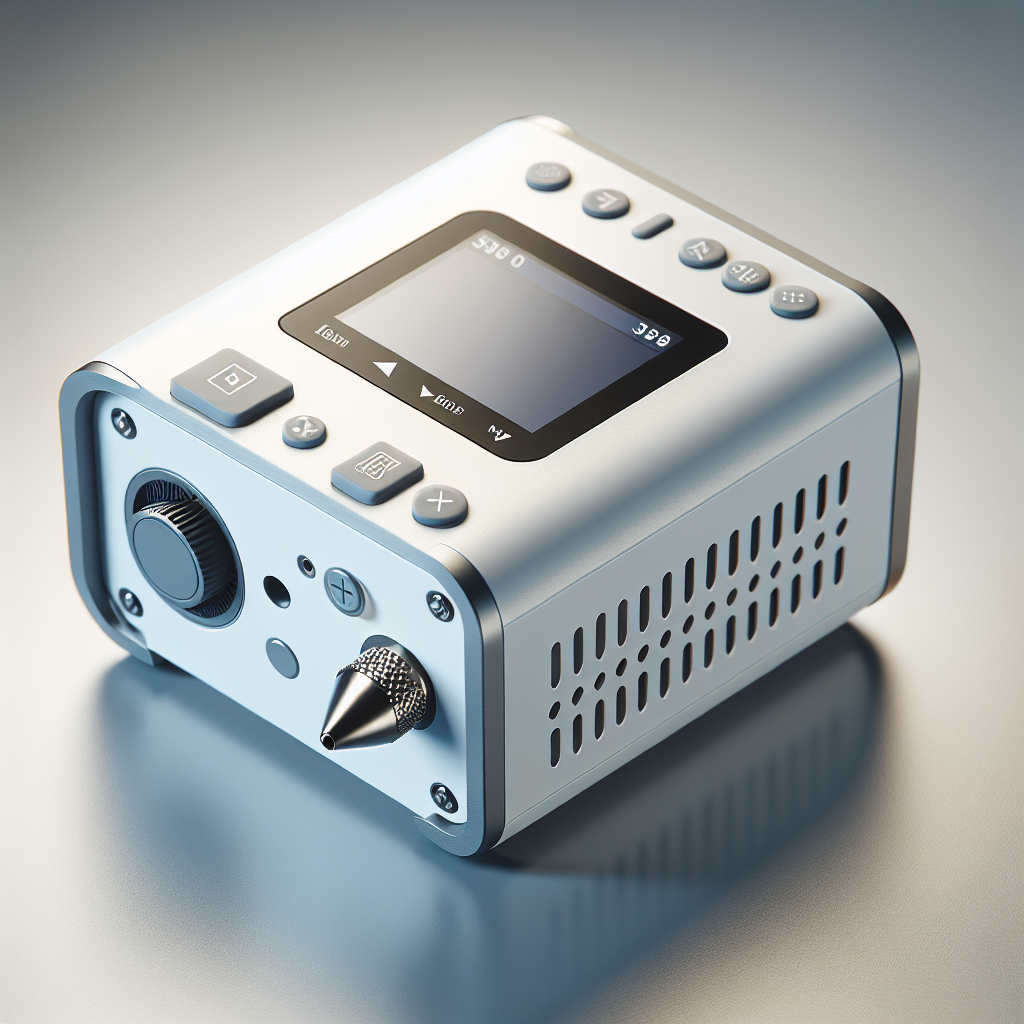

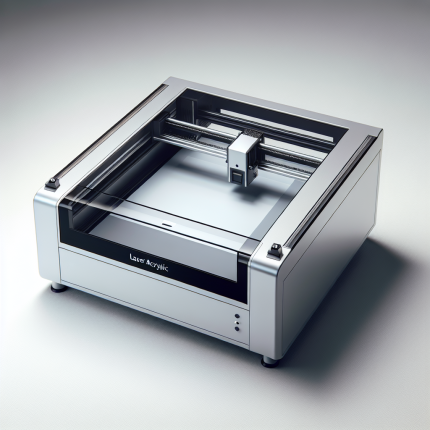

A mini laser engraver, also known as a laser acrylic cutter, is a versatile tool designed for precision cutting and engraving on various materials. These devices are widely used by hobbyists, crafters, and small businesses due to their compact size and high accuracy. Whether you’re creating custom designs for acrylic, wood, or metal, a mini laser engraver offers a user-friendly solution for intricate detailing. In this guide, we’ll explore the features, technical specifications, applications, and benefits of using a mini laser engraver in your projects.

What is a Mini Laser Engraver?

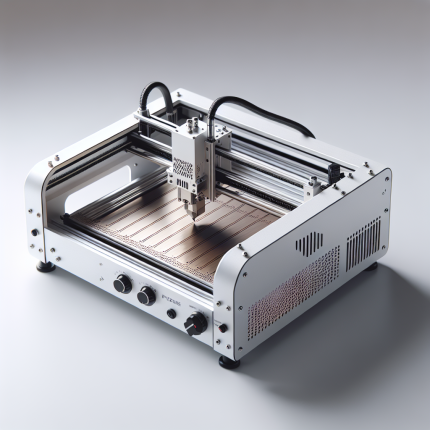

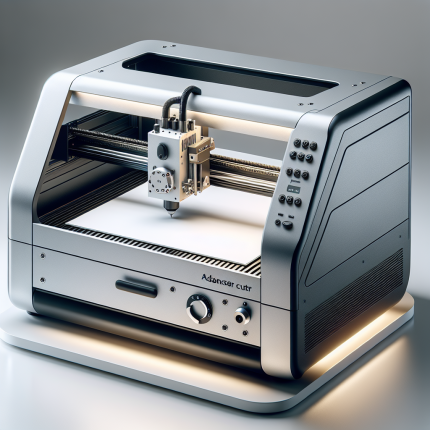

A mini laser engraver combines advanced laser technology with CNC (Computer Numerical Control) functionality to etch or cut materials with precision. Unlike traditional engraving tools, these machines use a focused laser beam to remove material layer by layer, resulting in crisp and detailed designs. The compact design of a mini laser engraver makes it ideal for small-scale projects, saving space while maintaining professional-grade performance.

Key Features of a Mini Laser Engraver

- Precision Cutting: Capable of cutting materials with extreme accuracy, making it suitable for delicate designs.

- Versatile Material Compatibility: Works on acrylic, wood, leather, paper, and other non-metallic materials.

- User-Friendly Interface: Equipped with intuitive software that simplifies the design-to-output process.

- Compact Design: Portable and space-saving, perfect for home workshops or small offices.

Technical Specifications of a Mini Laser Engraver

Understanding the technical specifications is crucial when selecting the right mini laser engraver for your needs. Below are some key specs to consider:

Power Output

- Laser Power: Typically ranges from 20W to 100W, depending on the model and intended use. Higher power lasers are suitable for cutting thicker materials like acrylic sheets.

Laser Type

- Diode Lasers: The most common type used in mini engravers due to their efficiency and compact size.

Working Area

- Engraving Area: Ranges from 120x90mm to 450x300mm, depending on the model. Larger working areas are better for bigger projects.

Repetition Accuracy

- Precision: Typically measures in micrometers, with most mini laser engravers offering ±0.005mm accuracy.

Additional Features

- Focus Lens: Ensures precise beam focusing for cleaner cuts and engravings.

- Cooling System: Many models include built-in cooling to maintain optimal performance during extended use.

Applications of a Mini Laser Engraver

A mini laser engraver is a multi-functional tool with applications across various industries:

1. Hobby and Craft Projects

- Create personalized jewelry, decorative items, or custom name tags with intricate designs.

2. Signage and Display Making

- Cut and engrave acrylic letters, logos, and signage for businesses or promotional materials.

3. Prototyping

- Ideal for creating small-scale prototypes in product development.

4. Educational Use

- Perfect for teaching CNC machining and laser technology in schools or workshops.

Advantages of Using a Mini Laser Engraver

- Precision and Detail: Produces high-quality engravings with sharp edges and smooth surfaces.

- Time Efficiency: Quickly cuts and engraves materials, reducing production time compared to manual methods.

- Cost-Effective: Suitable for small-scale projects, minimizing material waste.

- User-Friendly Operation: Easy to set up and use, even for beginners.

How Does a Mini Laser Engraver Compare to Traditional Methods?

Compared to traditional engraving tools or CNC machines, a mini laser engraver offers several advantages:

- Precision: The focused laser beam ensures cleaner cuts with minimal material damage.

- Speed: Processes materials faster than manual engraving techniques.

- Material Versatility: Works on a wide range of materials without the need for different cutting tools.

Frequently Asked Questions (FAQ)

1. What materials can I cut or engrave with a mini laser engraver?

You can work with materials like acrylic, wood, leather, paper, and some plastics. Always check compatibility before use to avoid damage to your equipment.

2. Is a mini laser engraver safe to use?

Yes, most models come equipped with safety features like emergency stop buttons and enclosed laser chambers. Follow the manufacturer’s guidelines for safe operation.

3. How easy is it to learn how to use a mini laser engraver?

The user-friendly interface and intuitive software make it accessible even for those new to laser cutting technology. Tutorials and guides are often provided with the machine.

4. What maintenance does a mini laser engraver require?

Regular cleaning of the lens and checking the cooling system are essential to ensure optimal performance. Follow the maintenance schedule recommended by the manufacturer.

5. Can I use a mini laser engraver for industrial purposes?

While designed for small-scale projects, some models can handle light industrial tasks if they meet your specific requirements in terms of power and working area.

Conclusion

A mini laser engraver is an indispensable tool for anyone looking to create precise and detailed engravings or cuts on various materials. With its compact design, high accuracy, and versatility, it’s a great investment for hobbyists, educators, and small businesses alike. By understanding the technical specifications and applications, you can make an informed decision when choosing the right mini laser engraver for your projects.

If you have more questions or need further assistance, feel free to explore our other resources on laser cutting technology or reach out to our support team.

Hong Rivera (verified owner) –

This laser engraver excels in versatility across materials like wood, acrylic, and leather. On wood, intricate details are sharp, while acrylic demands precise power control to avoid warping. Leather engraves smoothly, creating elegant textures. Its speed is commendable for large projects but slows slightly on complex patterns. Ideal for workshops or home studios, it handles both artistic engravings (e.g., custom jewelry boxes) and practical tasks (e.g., signage制作). The software interface is user-friendly, though a learning curve exists for advanced settings. Overall, a reliable tool with minor room for speed optimization on delicate materials.

Mariana Young (verified owner) –

The laser engraver excels in user experience with an intuitive software interface that streamlines project setup, even for newcomers. Its standout feature is the library of preset templates, which significantly reduces the learning curve. Compared to similar models, it offers enhanced customization options, allowing precise control over intricate designs. While the initial calibration was straightforward, minor adjustments were needed for optimal performance on acrylic materials. Overall, its ease of use and versatility make it ideal for both hobbyists and professionals, offering exceptional value with a competitive price-performance ratio.

Jose Park (verified owner) –

The laser engraver excels in precision and speed across materials like wood, acrylic, and leather. For instance, intricate designs on wood showcase sharp detail, while acrylic projects benefit from smooth etching. The learning curve is minimal, thanks to intuitive software that simplifies project setup. A standout feature is its auto-focusing mechanism, ensuring consistent results even for complex patterns. Ideal for home workshops or small businesses, it handles both artistic and functional projects with ease. While the price-performance ratio is strong, consider factoring in long-term maintenance costs for optimal ROI.

Jean Bruno (verified owner) –

**Laser Engraver Experience Review**

As an art teacher, I’ve found laser engraving to be a transformative tool for my creative and professional workflow.

### Specific Project Experience

I recently used the laser engraver for custom wedding decorations, including engraved acrylic place cards, personalized wood coasters, and delicate glass etching. Each material behaved uniquely: wood offered deep contrast with darker engravings, acrylic produced vibrant results when paired with colored sheets, and glass required careful speed adjustments to avoid cracking.

One challenge was preventing discoloration in acrylics during engraving, which I solved by testing power settings on scrap materials first. For glass, slow speeds ensured clean lines without chipping.

### Technical Performance

The laser’s high power (120W) delivered crisp precision, even for intricate designs like wedding motifs. The software was user-friendly, allowing seamless design imports and adjustments for different materials. I appreciated the ability to preview engraving paths before printing, minimizing errors.

Special features like vector cutting were invaluable for creating precise shapes and cutouts, enhancing both creativity and efficiency.

### Business/Creative Impact

The laser engraver significantly sped up my workflow compared to traditional carving methods. Customers praised the quality and uniqueness of the engraved items, leading to repeat business and referrals. The return on investment was evident within six months due to increased productivity and demand for custom work.

### Comparison & Value

Compared to manual tools or CNC machines, this laser engraver is faster, more precise, and versatile across materials. Its cost-effectiveness shines in producing high-quality, custom items efficiently, making it an invaluable addition to my studio.

Ivan Ma (verified owner) –

This little laser engraver is a lifesaver for my crafting projects! It’s super easy to use and did an incredible job cutting out clean, precise business logos from acrylic sheets. Highly impressed with its versatility—it’s become my go-to tool!

Hiroshi Wilson –

★★★★★ Exceptional laser engraver! The etching precision is flawless, and the results are stunning. Operation is seamless, software intuitive. Fast雕刻, boosts productivity. Solid build, highly reliable.