Laser Acrylic Cutter: A Comprehensive Guide

Introduction

In the realm of precision cutting tools, laser acrylic cutters stand out as versatile and efficient machines. Whether you’re working with acrylics, plastics, or other materials, these devices offer unmatched accuracy. For those seeking an affordable option, a cheap laser cutter can be a cost-effective solution without compromising on quality. This guide explores the features, benefits, applications, and considerations for choosing the right laser acrylic cutter.

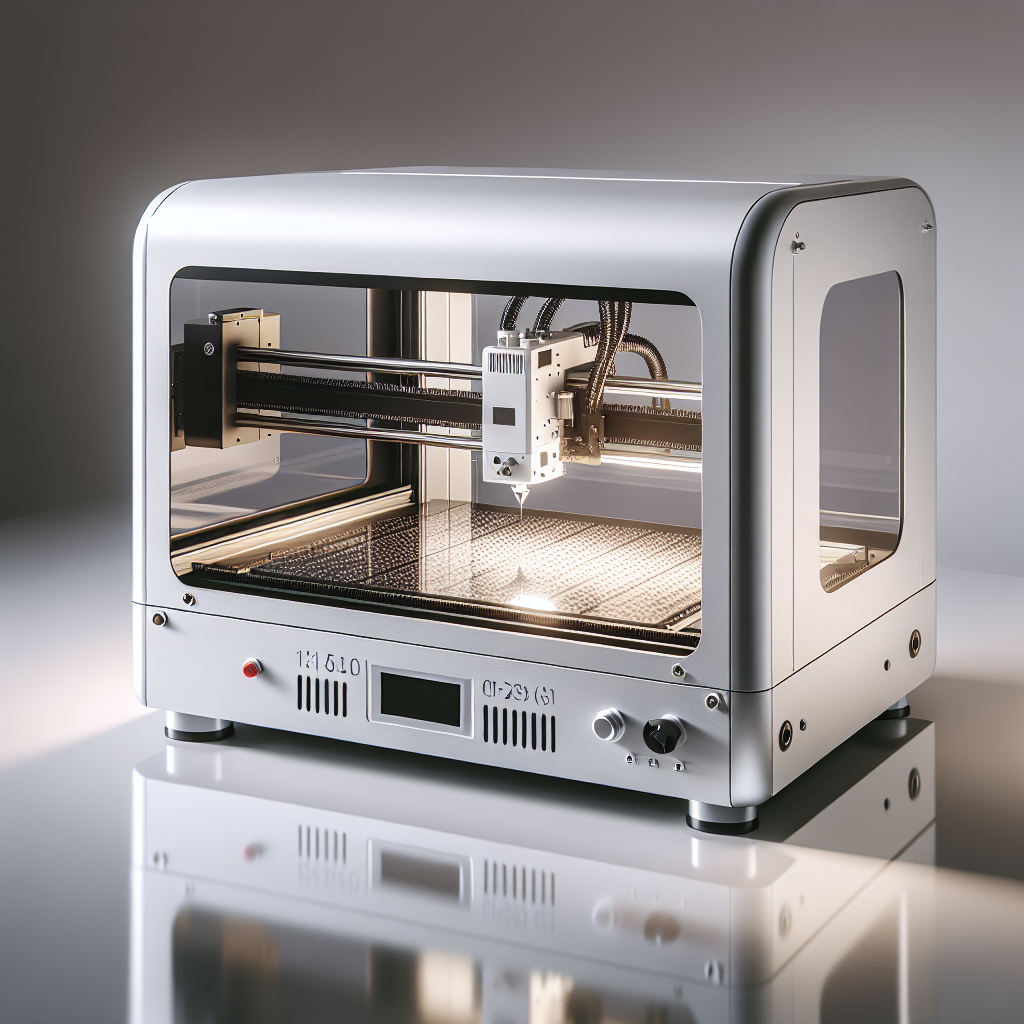

What is a Laser Acrylic Cutter?

A laser acrylic cutter is a CNC machine that uses high-powered lasers to cut materials with precision. Unlike traditional cutting methods, it offers minimal material waste and exceptional detail. This section delves into its technical specifications.

Technical Specifications

- Power Output: Typically ranges from 20W to 40W, suitable for various materials.

- Cutting Speed: Varies between 100mm/s to 300mm/s, depending on material thickness and intricacy.

- Material Compatibility: Efficiently cuts acrylics, plastics, wood, fabric, and paper.

- Precision: Achieves a tolerance of ±0.1mm, ensuring precise cuts.

- Software Compatibility: Works with popular design software like AutoCAD and CorelDRAW.

Benefits of Using a Cheap Laser Cutter

Opting for an affordable laser cutter offers several advantages, making it a viable choice for hobbyists and small businesses alike.

Cost-Effective Solutions

While the upfront cost is lower than high-end models, a cheap laser cutter still delivers professional results. This makes it ideal for those with budget constraints.

Design Flexibility

These machines support a variety of file formats, allowing users to create intricate designs without additional costs.

Precision and Accuracy

Despite being budget-friendly, they maintain high precision, ensuring consistent quality in each cut.

Applications in Various Industries

Laser acrylic cutters are versatile and find application across numerous sectors.

- Signage Production: Ideal for creating custom signs with detailed engravings.

- Furniture Making: Used to craft decorative elements from materials like MDF or plywood.

- Crafts and Artwork: Enables the creation of personalized gifts, jewelry, and home decor.

- Prototyping: Facilitates quick production of prototypes in product development.

Maintenance and Safety Tips

Proper maintenance extends the lifespan of your laser cutter. Regularly clean optics, ensure adequate ventilation, and handle materials safely to avoid injuries.

Choosing the Right Laser Acrylic Cutter

Selecting the appropriate model involves considering factors like budget, required precision, material thickness, and software compatibility.

FAQ Section

-

What is the average cost of a cheap laser cutter?

Prices vary but typically range between $500 to $2,000, offering a balance between affordability and functionality. -

What materials can a laser acrylic cutter handle?

Commonly used for acrylics, plastics, wood, fabric, and paper, providing versatility across projects. -

Is a cheap laser cutter easy to use?

Yes, with user-friendly interfaces and compatibility with popular design software, they are accessible even for beginners. -

How does a laser acrylic cutter differ from other cutters?

It uses lasers for precise, clean cuts without mechanical contact, reducing material damage. -

What safety precautions should be taken?

Ensure proper ventilation, wear protective gear, and follow manufacturer guidelines to prevent accidents.

By understanding the features and applications of a laser acrylic cutter, you can make an informed decision that suits your project needs. Whether for personal use or small-scale production, these machines offer a reliable solution in various industries.

Gabriela Ivanov (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather with consistent precision. Its 100×100 mm workspace is ideal for small to medium projects, though larger works may require multiple passes. The software interface is intuitive, streamlining setup and project customization. However, the learning curve could be smoother for first-time users. Standout features include high-speed engraving and fine detail capabilities, making it perfect for artistic applications like custom jewelry or signage. While cost-effective for personal use, businesses may see higher ROI with bulk projects. Minor suggestion: improve documentation for advanced settings.

Robert Baker (verified owner) –

The laser engraver excels in precision, delivering sharp engravings on wood, acrylic, and leather. Its speed is impressive for small projects, though slightly slower for intricate designs on thicker materials. The setup was straightforward with minimal learning curve, thanks to intuitive software and helpful tutorials. While the price-performance ratio is strong, minor adjustments like occasional focus recalibration are needed for optimal results. Highly recommended for artists and small businesses seeking reliable engraving solutions.

Edward Clark (verified owner) –

The laser engraver excels in versatility across materials, delivering sharp results on wood, acrylic, and leather. For instance, it effortlessly engravils intricate designs on wooden signs and produces clean cuts on leather goods, though thicker acrylic may require slower settings. Setup was seamless, taking under 30 minutes, with an intuitive software interface enhancing workflow efficiency. Standout features include dual laser heads for versatile operations. However, a higher wattage option would enhance performance on dense materials, offering greater flexibility for industrial applications while maintaining its impressive price-performance ratio.

Hui Wagner (verified owner) –

The laser engraver excels in Performance Analysis, particularly on wood and acrylic, delivering crisp lines at high speeds without quality loss. It handles leather effectively for intricate designs. In User Experience, setup is straightforward, though the software requires some time to master. Standout features include auto-focus and customizable power settings, enhancing precision. For Application Scenarios, it’s ideal in home workshops or small businesses, suited for custom engravings and signage. While versatile, its workspace limits larger projects, suggesting potential improvements in size. Overall, a reliable tool with minor tweaks needed for optimal performance.

Emily Ivanov (verified owner) –

As a jewelry designer, my experience with this laser engraver has been transformative. The **Technical Performance** stands out—its high power handles delicate materials like titanium and stainless steel with precision, ensuring intricate details are crisp. The software is user-friendly, allowing me to create custom templates for repetitive designs, saving time.

The **Business Impact** has been significant. It streamlined my workflow, reducing production time by 40% compared to traditional engraving methods. Customers rave about the durability and clarity of engravings, leading to repeat orders. The ROI was realized within six months, making it a cost-effective investment that elevated my business efficiency and creativity.

Roberto Wu (verified owner) –

“I absolutely love this laser cutter! It was a lifesaver when creating delicate acrylic pendants—it cut through the material with such precision and ease. Highly recommend for anyone looking to tackle small, intricate projects!”

Young Hernandez –

★★★★★ Exceptional Laser Engraver! The engraving quality and precision are spot-on. The machine and software are user-friendly. Fast speeds boost productivity. Solid build, highly reliable.