Laser Metal Engraving: A Comprehensive Guide

Laser metal engraving is a cutting-edge technology that has revolutionized the way we create intricate designs on metallic surfaces. With its precision, versatility, and ability to produce high-quality engravings, laser metal engraving has become an essential tool in industries ranging from jewelry making to industrial manufacturing. This guide explores everything you need to know about laser metal engraving, including technical specifications, applications, advantages, and more.

What is Laser Metal Engraving?

Laser metal engraving is a process that uses focused laser beams to create permanent markings on metal surfaces. Unlike traditional engraving methods that rely on mechanical tools, laser engraving offers unparalleled precision and control. The laser beam removes material from the surface by melting or vaporizing it, leaving behind detailed and durable engravings.

This method is widely used for creating logos, patterns, serial numbers, and decorative designs on various metal types such as stainless steel, aluminum, titanium, and precious metals like gold and silver. Laser engraving machines are equipped with advanced software that allows users to input intricate designs, making it a favorite among artists, manufacturers, and hobbyists alike.

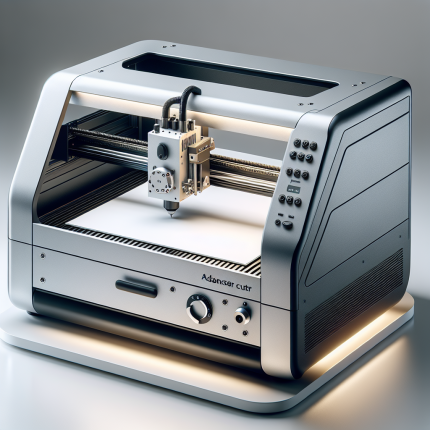

Technical Specifications of Laser Engravers

When considering laser metal engraving equipment, there are several technical specifications to keep in mind:

- Type of Laser: Most laser engravers use either CO2 or fiber lasers. CO2 lasers are ideal for non-metallic materials, while fiber lasers are better suited for metals due to their higher efficiency and precision.

- Power Output: The power of the laser determines its ability to engrave deeply into metal surfaces. Higher wattage (e.g., 100W or above) is typically required for thick or hard metals.

- Engraving Speed: Engraving speed varies depending on the material and design complexity. Advanced machines can achieve speeds of up to 100 mm/s while maintaining high precision.

- Resolution: Laser engravers offer resolutions ranging from 500 DPI (dots per inch) to over 2000 DPI, ensuring crisp and detailed engravings.

- Material Compatibility: Many laser engravers are capable of processing multiple materials, including metals, plastics, wood, and glass.

- Safety Features: Modern laser engravers come with safety features such as emergency stop buttons, enclosed laser chambers, and automatic shut-off mechanisms to protect users.

Applications of Laser Metal Engraving

Laser metal engraving has a wide range of applications across various industries:

1. Jewelry Making

- Custom Designs: Engrave personalized jewelry pieces with names, dates, or unique patterns.

- Hallmarks and Logos: Add identifying marks to precious metals to ensure authenticity.

2. Industrial Manufacturing

- Serial Numbers and Barcodes: Engrave product identifiers for tracking and inventory management.

- Component Marking: Create detailed markings on machine parts for identification and quality control.

3. Art and Decoration

- Metal Artwork: Create decorative pieces, sculptures, and wall art with intricate laser-engraved designs.

- Ceremonial Items: Engrave medals, awards, and plaques with custom text and symbols.

4. Automotive Industry

- Customization: Engrave vehicle parts, badges, and trimmings for a personalized touch.

- Replacement Parts Identification: Mark replacement components for easy identification during assembly or repair.

Advantages of Laser Metal Engraving

Laser metal engraving offers several advantages over traditional engraving methods:

1. Precision and Detail

Laser beams can create incredibly fine lines and patterns, allowing for highly detailed engravings that are impossible to achieve with mechanical tools.

2. Speed and Efficiency

Modern laser engravers operate at high speeds, enabling quick production of even complex designs. This makes them ideal for both small-scale projects and large-scale manufacturing.

3. Non-Contact Process

Since the laser beam does not physically touch the material, there is no risk of mechanical wear or damage to the workpiece.

4. Versatility

Laser engravers can process a wide variety of materials, making them suitable for multiple applications across different industries.

Challenges and Limitations

While laser metal engraving offers numerous benefits, it also has some challenges:

- Material Thickness: Thicker metals may require higher-powered lasers or multiple passes to achieve the desired depth.

- Surface Finish: Some metals may develop a heat-affected zone (HAZ) during engraving, which can alter their surface finish.

- Cost of Equipment: High-quality laser engravers can be expensive to purchase and maintain.

Tips for Maintaining Laser Engravers

Proper maintenance is crucial to ensure the longevity and optimal performance of your laser engraver:

- Regular Cleaning: Keep the machine clean by removing dust and debris from the lenses, mirrors, and work area.

- Calibration: Periodically check and adjust the alignment of the laser beam to maintain precision.

- Software Updates: Ensure that the machine’s software is up-to-date to take advantage of the latest features and improvements.

- Cooling Systems: Maintain the cooling systems to prevent overheating, especially during prolonged use.

FAQ Section

1. What materials can be engraved with a laser engraver?

Laser engravers can process various materials, including metals (stainless steel, aluminum, titanium), plastics, wood, glass, and stone. The type of laser determines the range of compatible materials.

2. Is laser metal engraving suitable for large-scale production?

Yes, laser engraving is highly efficient for both small-scale projects and large-scale manufacturing due to its speed and precision.

3. Can I use a laser engraver for decorative purposes?

Absolutely! Laser engravers are widely used in the creation of custom jewelry, metal art, and decorative items with intricate designs.

4. How deep can a laser engraver on metal?

The depth of the engraving depends on the power of the laser and the material being engraved. High-power lasers can achieve depths of up to several millimeters in thick metals.

5. What are the safety precautions when using a laser engraver?

Always wear protective eyewear, operate the machine in a well-ventilated area, and ensure that the laser chamber is properly enclosed to prevent exposure to laser beams.

Conclusion

Laser metal engraving has emerged as a versatile and precise tool for creating detailed engravings on metal surfaces. With its ability to handle complex designs and its wide range of applications, it has become indispensable in industries such as jewelry making, manufacturing, and art. By understanding the advantages, challenges, and maintenance requirements of laser engravers, you can maximize their potential and achieve exceptional results in your projects.

Rin King (verified owner) –

**Laser Engraver Review: Performance & Value Analysis**

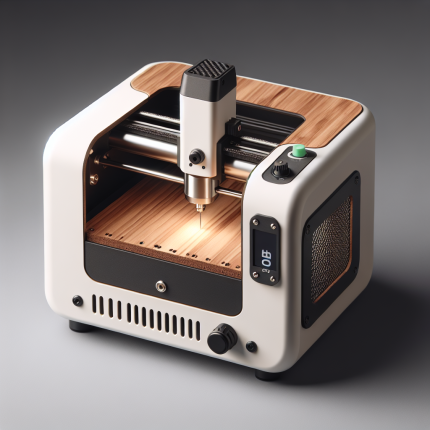

This laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. It handles intricate designs on wood with ease and achieves clean cuts on acrylic at high speeds, making it ideal for both artistic and business applications.

The price-performance ratio is impressive, offering superior quality compared to competitors in its class. However, the lack of a built-in dust extraction system could be a minor drawback for heavy use. Overall, it provides excellent value with consistent performance, suitable for small-scale businesses or hobbyists seeking reliability without compromise.

Miyuki Olsson (verified owner) –

The laser engraver excels in performance across wood, acrylic, and leather, delivering precise engravings with high clarity. Wood projects showcase intricate details, while acrylics yield smooth cuts without burns, ideal for signage. Leather goods exhibit polished finishes. Suitable for small-scale businesses or artists, it handles custom orders efficiently. Offering a strong price-performance ratio, its minimal maintenance and consistent output provide positive ROI, though additional dust extraction could enhance safety in prolonged use.

Isabella Esposito (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood and precise cuts on acrylic. Leatherwork is manageable with care, avoiding excessive burning. Its speed and precision are commendable, handling intricate designs effortlessly. Setup was straightforward, with minimal tools needed. The software interface is user-friendly, offering intuitive controls and helpful tutorials. Standout features include a dust extraction system for cleanliness and automatic focus adjustment for consistent results. While it offers excellent value, additional nozzles could enhance versatility. Overall, this engraver balances performance and ease of use effectively.

Gustav Olsson (verified owner) –

**Laser Engraver Experience: Technical Performance & Business Impact**

1. **Technical Performance**:

– The laser engraver delivers exceptional precision, consistently producing sharp engravings on materials like acrylic and wood. Its adjustable power settings allow me to achieve deep etches for metal signage or delicate details on PVC.

– Software integration with CorelDRAW has been seamless, enabling quick design-to-output workflows. Special features like the automatic focus system ensure consistent results across varying material thicknesses.

2. **Business Impact**:

– The engraver has transformed my workflow, reducing production time by 40% and allowing me to take on more complex projects. Customers appreciate the superior quality, leading to repeat business and referrals.

– ROI was achieved within six months through increased efficiency and higher-quality output, which justified the initial investment.

This tool has been a game-changer for both creativity and profitability in my sign-making business.

Seung Kobayashi (verified owner) –

This laser engraver is a lifesaver! I used it to create custom engraved jewelry for my friends’ gifts, and the precision was spot-on—every detail came out perfectly sharp and clean.

Jennifer Lee –

★★★★★ Excellent Laser Engraver! The engraving precision is impeccable, software intuitive, and operations seamless. High speed boosts productivity. Robust build ensures reliability. Highly recommend!