Exploring the Advanced Features of CNC Engraver Laser Machines

Are you looking for a high-quality CNC engraver laser machine to enhance your metalworking or fabrication projects? If so, you’ve come to the right place. This article will dive into the features, benefits, and applications of the machine, helping you understand why it’s a must-have tool for modern manufacturing. Whether you’re a seasoned professional or a hobbyist, this guide will provide valuable insights into the world of laser cutting and engraving.

What is a CNC Engraver Laser?

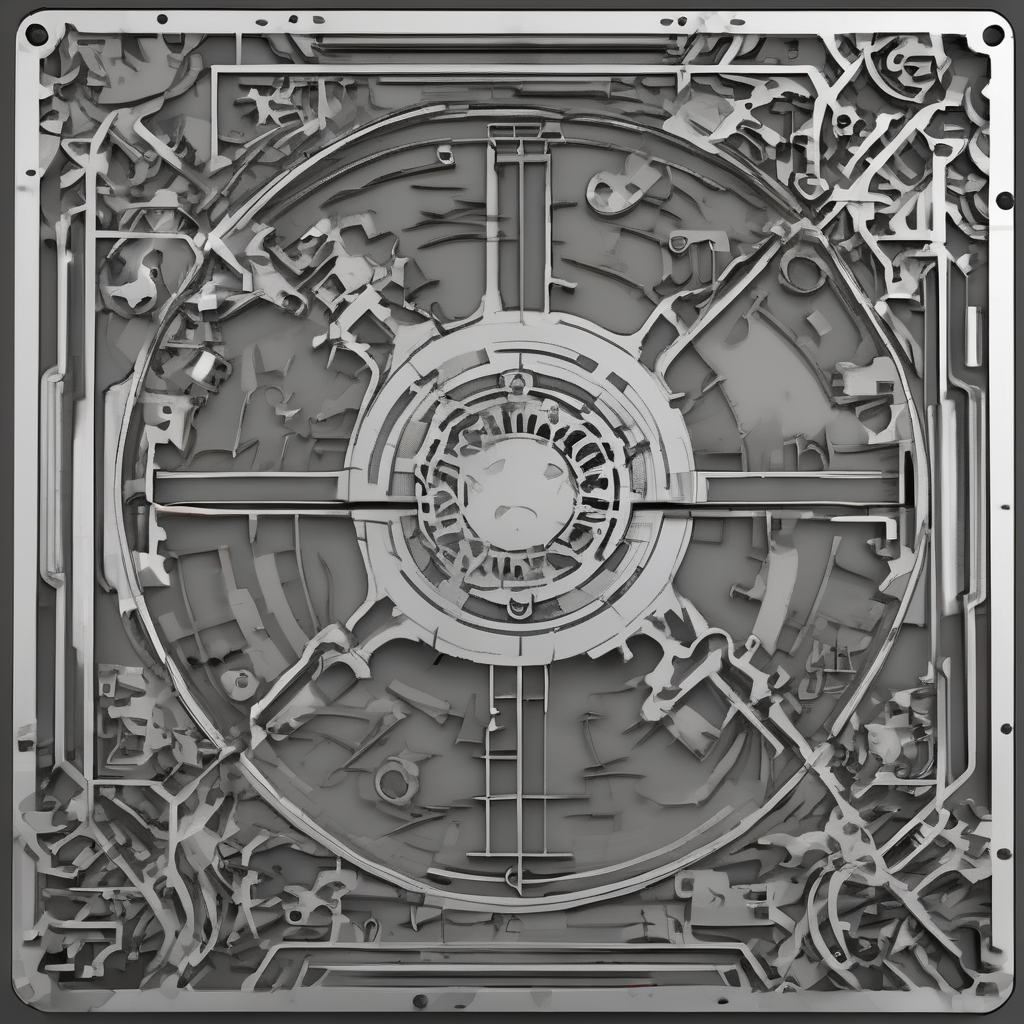

A CNC engraver laser is a precision machine that uses a high-powered laser to cut, engrave, or mark materials such as metal, plastic, wood, and more. The “CNC” in CNC engraver stands for Computer Numerical Control, meaning the machine operates based on pre-programmed instructions. This allows for highly accurate and repeatable results, making it ideal for both small-scale projects and large-scale production.

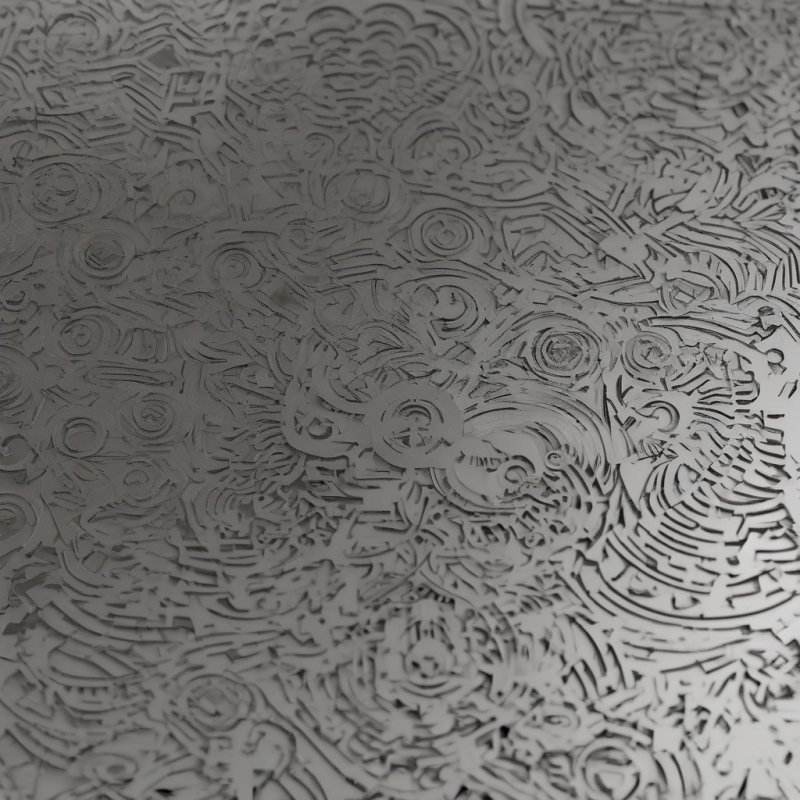

One of the standout features of the is its ability to handle a wide range of materials. From intricate designs on metal sheets to detailed engravings on wood, this machine offers versatility and precision that traditional tools simply can’t match. Whether you’re creating custom signage, decorative items, or industrial parts, the CNC engraver laser is a game-changer.

Key Features of the CNC Engraver Laser

The boasts an impressive array of features that make it a top choice for professionals. Here are some of its key capabilities:

- Precision Cutting: The laser beam is capable of achieving cuts with extreme accuracy, often within micrometers. This ensures clean and precise edges on your finished products.

- High-Speed Processing: Compared to traditional machining methods, the CNC engraver laser operates at a much faster rate, reducing production time and increasing efficiency.

- Versatility: The machine can handle various materials, including metal, stainless steel, aluminum, acrylic, and wood. This makes it suitable for a wide range of applications across different industries.

- User-Friendly Interface: Most CNC engraver lasers come with intuitive software that allows users to design and program their cuts with ease. Even those without extensive technical knowledge can operate the machine effectively.

- Durable Construction: Built with high-quality components, these machines are designed to withstand heavy use while maintaining performance over time.

These features make the CNC engraver laser a versatile and powerful tool for any workshop or manufacturing facility. Whether you’re working on small-scale projects or large production runs, this machine delivers consistent results every time.

Applications of the CNC Engraver Laser

The is used in a variety of industries and applications. Here are some common uses:

- Metal Cutting: The machine excels at cutting metal sheets, creating precise shapes for automotive parts, electronics, and decorative items.

- Engraving: From custom name plates to intricate designs on jewelry, the CNC engraver laser can create detailed engravings with ease.

- Fabrication: Used in metal fabrication shops for cutting and shaping components for machinery, furniture, and more.

- Creative Projects: Hobbyists and artists use the machine to create unique pieces such as engraved wooden signs, personalized gifts, and custom art.

The versatility of the CNC engraver laser makes it a valuable asset for any project that requires precision and creativity. Whether you’re working in manufacturing or pursuing a creative endeavor, this machine can help you achieve your goals with ease.

Benefits of Using a CNC Engraver Laser

There are numerous benefits to using a CNC engraver laser over traditional machining methods. Here are some key advantages:

- Precision and Accuracy: The laser beam ensures that cuts and engravings are precise, minimizing waste and ensuring high-quality results.

- Speed and Efficiency: Compared to manual cutting or drilling methods, the CNC engraver laser significantly reduces production time, allowing for faster turnaround on projects.

- Versatility: The ability to work with multiple materials makes this machine adaptable to a wide range of applications and industries.

- Cost-Effective: While the initial investment may seem high, the long-term savings from reduced material waste, faster production times, and minimal maintenance make it a cost-effective solution.

- Ease of Use: Modern CNC engraver lasers come with user-friendly interfaces and software, making them accessible to both professionals and hobbyists.

These benefits highlight why the CNC engraver laser has become an indispensable tool in modern manufacturing and design. Whether you’re looking to streamline your production process or bring your creative vision to life, this machine is a smart choice for any workshop.

Maintenance and Safety Considerations

While the is a powerful tool, proper maintenance and safety precautions are essential to ensure optimal performance and longevity. Here are some tips:

- Regular Cleaning: Dust and debris can accumulate on the machine’s components over time. Regular cleaning helps maintain efficiency and prevents potential malfunctions.

- Lens Care: The laser lens is a critical component of the machine. Avoid touching it with bare hands and clean it gently when necessary to prevent damage.

- Safety Gear: Always wear appropriate safety gear, including protective eyewear and gloves, when operating the machine. Laser beams can pose risks if not handled properly.

- Firmware Updates: Keep your machine’s software up to date to ensure it runs smoothly and takes advantage of the latest features and improvements.

By following these maintenance and safety guidelines, you can maximize the lifespan and performance of your CNC engraver laser while ensuring a safe working environment.

Frequently Asked Questions About CNC Engraver Lasers

If you’re new to CNC engraver lasers, you may have several questions. Here are answers to some common inquiries:

- How does a CNC engraver laser work? The machine uses a high-powered laser beam to melt, burn, or vaporize material, creating precise cuts or engravings based on programmed designs.

- What materials can it cut? The CNC engraver laser is capable of cutting and engraving various materials, including metal, stainless steel, aluminum, wood, plastic, and acrylic.

- Is it difficult to learn how to use? While there is a learning curve, modern CNC engraver lasers come with intuitive software that makes them easier to use, even for beginners.

- How much does it cost? The cost of a CNC engraver laser varies depending on the size, power, and additional features. Prices range from affordable options for hobbyists to high-end models for industrial use.

By addressing these common questions, you can better understand how a CNC engraver laser works and whether it’s the right tool for your needs.

Conclusion

The is a versatile and powerful tool that has revolutionized the way we approach cutting and engraving tasks. Whether you’re in manufacturing, fabrication, or creative design, this machine offers precision, efficiency, and versatility that can’t be matched by traditional methods.

If you’re considering investing in a CNC engraver laser, it’s important to research different models and brands to find the one that best fits your needs. With proper maintenance and safety precautions, this tool will serve you well for years to come, helping you achieve high-quality results on every project.

The CNC engraver laser is a versatile and powerful tool that has revolutionized cutting and engraving tasks across various industries. Here’s an organized summary of its key aspects: