Exploring the Laser Wood Cutter and Engraver: Precision and Creativity

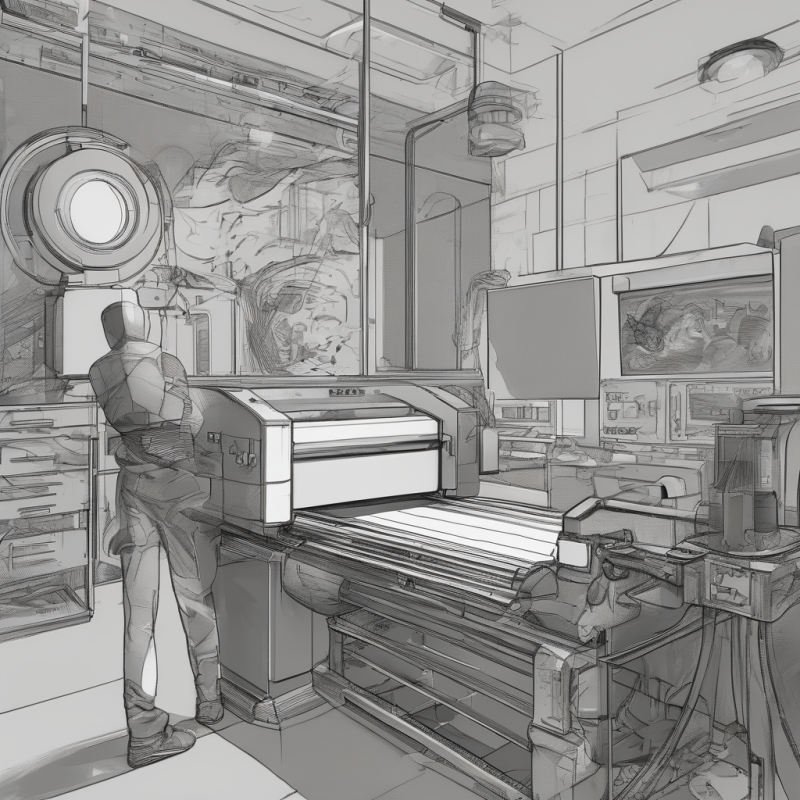

Are you searching for a versatile tool that combines precision, creativity, and efficiency? Look no further than the laser wood cutter and engraver. This innovative machine is revolutionizing industries by offering unparalleled capabilities in cutting and engraving materials like wood, metal, and more. Whether you’re a hobbyist, an artist, or a professional, this article will guide you through the features, benefits, and applications of the laser wood cutter and engraver, helping you determine if it’s the right choice for your projects.

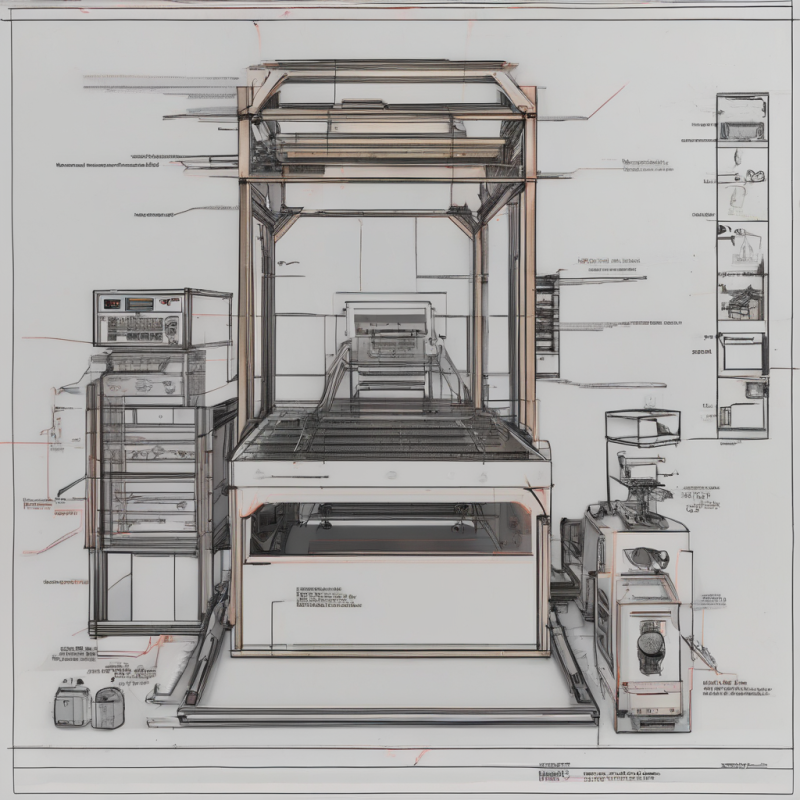

What is a Laser Wood Cutter and Engraver?

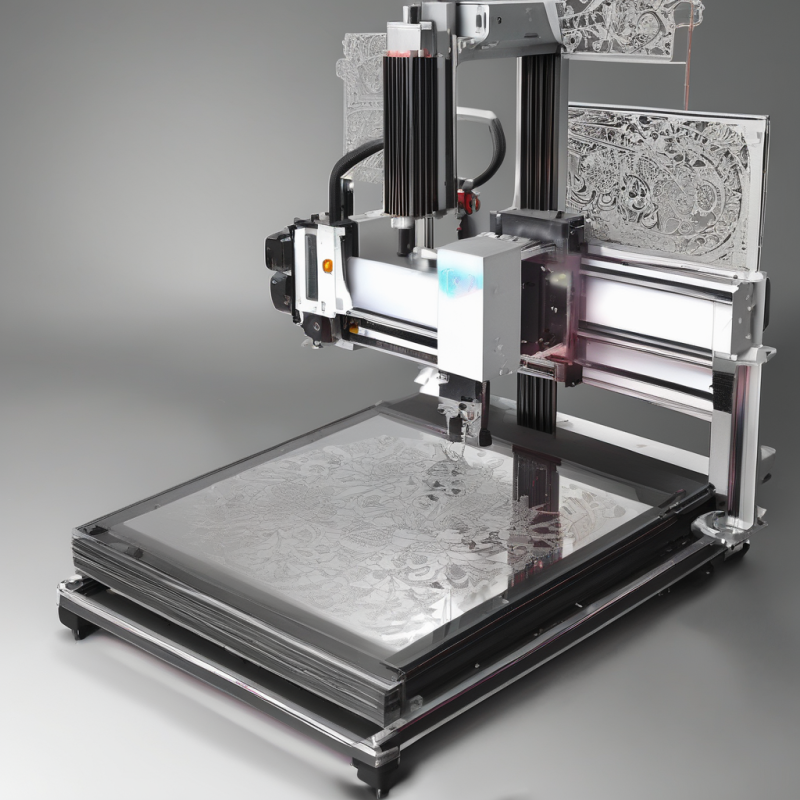

A laser wood cutter and engraver is a cutting-edge machine designed to perform precise cuts and engravings on various materials. Unlike traditional tools, this machine uses a laser beam to create intricate designs, patterns, and text with exceptional accuracy. The laser’s focused energy allows for non-contact processing, minimizing material deformation and ensuring clean, polished results.

The laser wood cutter and engraver is highly versatile, capable of handling materials such as wood, metal, plastic, leather, and even glass. Its ability to work with multiple materials makes it an invaluable tool for industries like woodworking, jewelry-making, signage production, and custom craft creation. Whether you’re crafting a one-of-a-kind piece or producing large-scale designs, this machine delivers consistent quality and performance.

Key Features of the Laser Wood Cutter and Engraver

The laser wood cutter and engraver boasts an array of features that set it apart from conventional tools. Here are some of its standout attributes:

- Precise Laser Cutting: The machine uses a high-powered laser to make clean, accurate cuts with minimal material waste.

- Advanced Engraving Capabilities: Create detailed designs and text on various surfaces, perfect for custom branding or artistic expressions.

- Versatile Material Compatibility: Works seamlessly with wood, metal, plastic, leather, and other materials, offering flexibility for diverse projects.

- User-Friendly Interface: Intuitive controls and software make it easy to operate, even for beginners.

- High-Speed Processing: Quickly complete tasks, reducing production time while maintaining quality.

These features ensure that the laser wood cutter and engraver is a reliable and efficient tool for both small-scale projects and large-scale production runs.

Applications of the Laser Wood Cutter and Engraver

The applications of the laser wood cutter and engraver are vast and varied, making it a valuable asset in numerous industries. Here are some common uses:

- Woodworking: Cut intricate designs, joints, and patterns for furniture, decorative items, and custom woodwork.

- Jewelry-Making: Engrave delicate details on metal and create unique pieces with precision.

- Signage Production: Create eye-catching signs with cut-out letters and detailed graphics.

- Custom Crafts: Personalize gifts, home decor, and other items with custom engravings and designs.

- Prototyping: Quickly produce prototypes for product development, ensuring accuracy and reducing costs.

No matter your project, the laser wood cutter and engraver provides the precision and versatility needed to bring your ideas to life.

Benefits of Using a Laser Wood Cutter and Engraver

Investing in a laser wood cutter and engraver offers numerous benefits that can elevate your projects and streamline your workflow. Some key advantages include:

- Enhanced Precision: The laser’s focused beam ensures clean, accurate cuts and engravings, eliminating the risk of human error.

- Time Efficiency: High-speed processing capabilities allow you to complete tasks quickly, reducing production time and increasing output.

- Clean Results: Non-contact processing minimizes material deformation and eliminates the need for additional finishing steps.

- Versatility: Capable of working with multiple materials, this machine is ideal for diverse projects and industries.

- Cost-Effective: Reduce waste and lower production costs by achieving precise cuts and engravings every time.

By incorporating a laser wood cutter and engraver into your toolkit, you can unlock new creative possibilities while improving efficiency and productivity.

How Does the Laser Wood Cutter and Engraver Work?

To understand how the laser wood cutter and engraver operates, let’s break down its basic principles:

The machine uses a laser beam, which is generated by a laser source and focused through optics. The laser’s energy is directed at the material being cut or engraved, creating precise incisions or markings. The process is controlled by software that translates your design into instructions for the machine, ensuring accurate execution of even the most complex patterns.

The key to its effectiveness lies in the laser’s ability to deliver concentrated energy without physically contacting the material. This non-contact method reduces the risk of damage and ensures clean, polished results. Whether you’re cutting through wood or engraving metal, the laser wood cutter and engraver adapts to your needs with ease.

Selecting the Right Laser Wood Cutter and Engraver

If you’re considering purchasing a laser wood cutter and engraver, it’s essential to evaluate your specific needs and choose a machine that aligns with them. Here are some factors to consider:

- Material Compatibility: Ensure the machine can handle the materials you’ll be working with, such as wood, metal, or plastic.

- Laser Power: Higher power lasers are better suited for thicker materials and more intricate designs.

- Software Integration: Look for machines that support popular design software to simplify the workflow.

- User-Friendliness: Opt for a machine with an intuitive interface, especially if you’re new to laser cutting and engraving.

- Budget: Determine your budget and select a machine that offers the best value for your needs.

Taking these factors into account will help you choose the right laser wood cutter and engraver to meet your project requirements.

Maintenance and Safety Tips

To ensure optimal performance and longevity of your laser wood cutter and engraver, it’s crucial to follow proper maintenance and safety protocols. Here are some tips:

- Regular Cleaning: Keep the machine clean by removing dust, debris, and residue after each use.

- Lens Care: Protect the laser optics from contamination by using lens cleaning solutions and covers when not in use.

- Software Updates: Regularly update the machine’s software to ensure it operates at peak efficiency.

- Operator Training: Provide proper training for anyone operating the machine to prevent accidents and ensure safe usage.

- Safety Gear: Always wear appropriate safety gear, including goggles and gloves, when working with the machine.

By following these guidelines, you can extend the life of your laser wood cutter and engraver while maintaining a safe work environment.

Frequently Asked Questions (FAQs)

Q: Can I use the laser wood cutter and engraver for both cutting and engraving?

A: Yes, most machines are designed to handle both cutting and engraving tasks. Simply adjust the settings based on your project’s requirements.

Q: Is it difficult to learn how to use a laser wood cutter and engraver?

A: While there is a learning curve, many machines come with user-friendly interfaces and software that make operation straightforward, even for beginners.

Q: Can I cut metal with a laser wood cutter and engraver?

A: Yes, as long as the machine has sufficient power and the appropriate settings are used. Always consult the manufacturer’s guidelines for specific materials.

Q: How often do I need to replace the laser tube?

A: Laser tubes typically last several thousand hours before needing replacement. Proper maintenance can extend their lifespan significantly.

Q: Is it safe to use a laser wood cutter and engraver at home?

A: Yes, but always follow safety guidelines, such as using protective gear and ensuring adequate ventilation to avoid inhaling fumes from materials being cut or engraved.

Conclusion

A laser wood cutter and engraver is a powerful tool that can revolutionize your woodworking, crafting, and prototyping projects. With its precision, versatility, and time-saving capabilities, it’s no wonder this technology has become increasingly popular among hobbyists and professionals alike.

If you’re looking to take your projects to the next level, investing in a laser wood cutter and engraver is a wise decision. By selecting the right machine and following proper maintenance and safety protocols, you can unlock new creative possibilities and achieve professional-quality results every time.

Whether you’re crafting custom furniture, creating unique jewelry, or producing signage, this versatile tool has the power to bring your ideas to life with unmatched precision and efficiency. So why wait? Start exploring the world of laser cutting and engraving today and see how it can transform your projects!

A laser wood cutter and engraver is a powerful tool that offers numerous benefits for various applications, from woodworking to crafting and prototyping. This guide provides an in-depth overview of its features, uses, and advantages, along with practical tips for selection and maintenance.