The Ultimate Guide to Choosing a CO2 Laser Cutter for Home Use

Are you looking for a versatile tool that can transform your DIY projects or small-scale manufacturing? A CO2 laser cutter might be the perfect solution! This article will guide you through everything you need to know about these machines, their features, applications, and how to choose the best one for your needs. Whether you’re a hobbyist, artist, or small business owner, this comprehensive guide has got you covered.

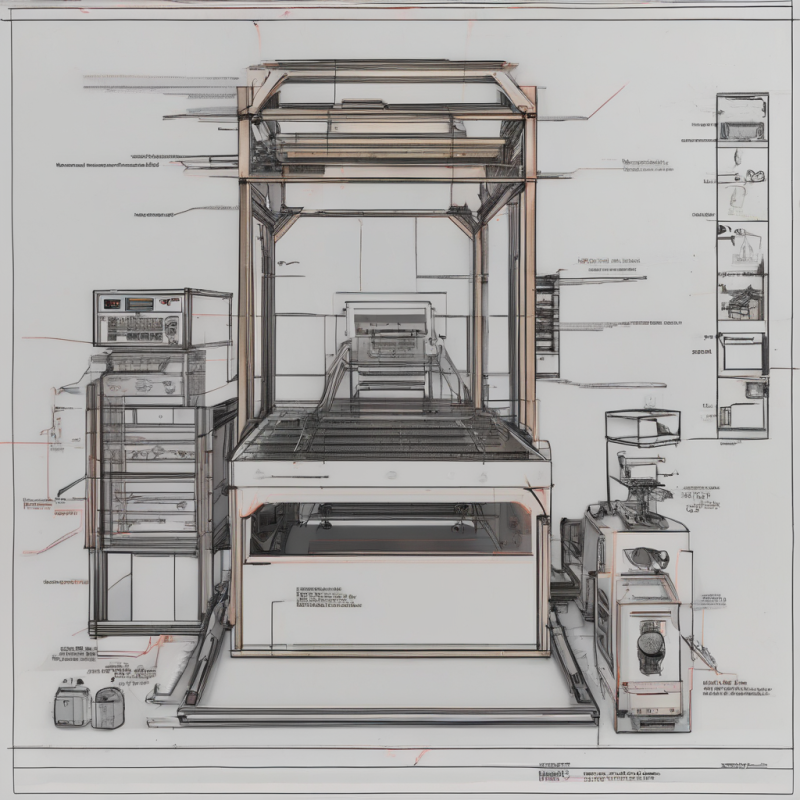

What is a CO2 Laser Cutter?

A CO2 laser cutter is a machine that uses a focused beam of light to cut, engrave, or etch materials such as wood, metal, plastic, and more. The term “CO2” refers to the gas used within the laser tube to generate the laser beam. These machines are highly precise and efficient, making them ideal for both industrial and home use.

One of the most significant advantages of a CO2 laser cutter is its ability to handle a wide range of materials. For example, wood can be cut with ease, while metal requires higher power settings. The versatility of these machines makes them a valuable addition to any workshop or creative space.

But how does it work? Let’s break it down. The laser beam is generated by passing an electric current through a mixture of carbon dioxide, nitrogen, and helium gases. This process creates a highly concentrated beam of light that can be directed with extreme precision. By adjusting the power and speed settings, you can control the depth and finish of your cuts or engravings.

Key Features to Look For

When choosing a CO2 laser cutter, there are several features to consider:

- Laser Power: Higher power lasers can cut through thicker materials, but they may also require more advanced safety precautions. A 40W to 60W laser is typically sufficient for home use.

- Cutting Precision: Look for machines with high-resolution optics to ensure clean and accurate cuts.

- Speed: Faster cutting speeds can save time, especially if you’re working on large projects. However, speed should never compromise precision.

- Safety Features: Ensure the machine has built-in safety measures like emergency stop buttons and protective covers to prevent accidents.

- Portability: Some models are designed for home use and can be easily moved or stored when not in use.

If you’re unsure which features are most important, consider your primary use case. For example, if you plan to work with delicate materials like paper or fabric, precision will be key. On the other hand, if you’re focusing on metalwork, a higher-powered machine may be necessary.

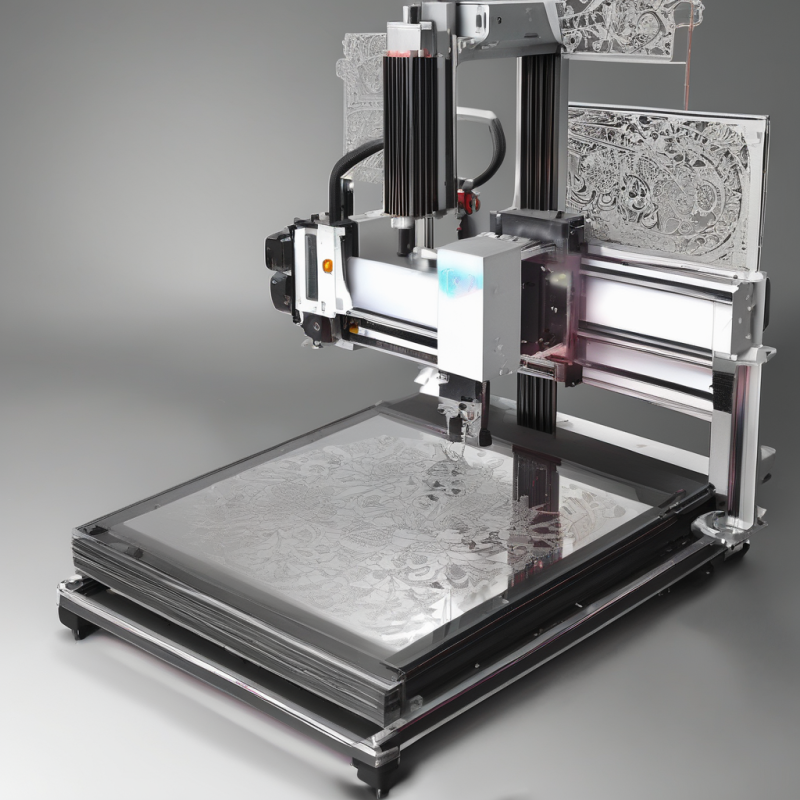

Applications of a CO2 Laser Cutter

The applications of a CO2 laser cutter are nearly endless! Here are some popular uses:

- Cutting Wood: Perfect for creating custom furniture, decorative items, or intricate designs.

- Engraving Metal: Ideal for personalized jewelry, signs, or tools.

- Fabric Etching: Great for creating unique patterns or logos on textiles.

- Plastic Prototyping: Quickly produce custom parts or models without the need for expensive molds.

If you’re thinking about purchasing a CO2 laser cutter, ask yourself: What materials will I be working with most frequently? This will help narrow down your options and ensure you choose the right machine for your needs.

Why Choose a CO2 Laser Cutter Over Other Options?

Compared to traditional cutting tools, a CO2 laser cutter offers several advantages:

- Precision: The focused beam allows for extremely detailed and accurate cuts, which is especially useful for complex designs.

- Versatility: It can handle a wide range of materials, making it a multi-functional tool for your workshop.

- Speed: Once programmed, the machine can complete tasks much faster than manual cutting methods.

- Cost-Effective: Over time, a CO2 laser cutter can save you money by reducing material waste and minimizing the need for expensive tools or labor.

For small businesses or hobbyists, the ability to create custom designs on-demand is a game-changer. You no longer have to rely on external manufacturers, giving you complete control over your projects.

Maintenance and Safety Tips

While CO2 laser cutters are powerful tools, they do require proper maintenance and safety precautions:

- Cleanliness: Regularly clean the lens to ensure optimal performance. Dust or debris can obstruct the laser beam.

- Protective Gear: Always wear safety goggles when operating the machine, and ensure your workspace is well-ventilated to avoid inhaling fumes from cutting materials.

- Software Updates: Keep the machine’s software up-to-date to access new features and improvements.

Remember, a well-maintained CO2 laser cutter can last for years, providing you with reliable service for all your projects. Always follow the manufacturer’s guidelines for operation and maintenance to maximize its lifespan.

How to Choose the Best CO2 Laser Cutter

If you’re ready to invest in a CO2 laser cutter, here are some tips to help you make the right choice:

- Budget: Determine how much you can spend. Entry-level models start at around $500, while high-end industrial machines can cost tens of thousands.

- Material Types: Consider the types of materials you’ll be working with most often. Some machines are better suited for certain materials than others.

- Cutting Area: Choose a machine with a cutting area that matches your project needs. Larger areas may require more space and power.

- Software Compatibility: Ensure the machine is compatible with your computer’s operating system and any design software you plan to use.

If you’re still unsure, do some research or read reviews from other users who have similar needs. This can provide valuable insights into which models perform best in real-world applications.

Conclusion

A CO2 laser cutter is a fantastic tool for anyone looking to take their DIY projects, art, or small-scale manufacturing to the next level. With its precision, versatility, and speed, it’s no wonder these machines are becoming increasingly popular among hobbyists and professionals alike.

If you’re ready to take the plunge, consider checking out our recommended models, such as the , which offers excellent performance for home use. Don’t forget to prioritize safety and maintenance to get the most out of your investment!

Now that you have a better understanding of how these machines work and what they can do, it’s time to start brainstorming your next project! Whether you’re creating custom furniture, personalized jewelry, or intricate artwork, a CO2 laser cutter will give you the freedom to bring your ideas to life.