Title: Best Laser for Engraving Tumblers

Introduction

The art of engraving on tumblers has evolved remarkably, thanks to innovations in laser technology. Whether you’re a hobbyist or a professional, selecting the best laser for engraving tumblers is crucial to enhancing the quality and efficiency of your projects. This article explores the latest laser engraving machines tailored for tumbler engraving, spotlighting their specifications, material compatibility, and much more.

Laser Engraving Technology and Applications

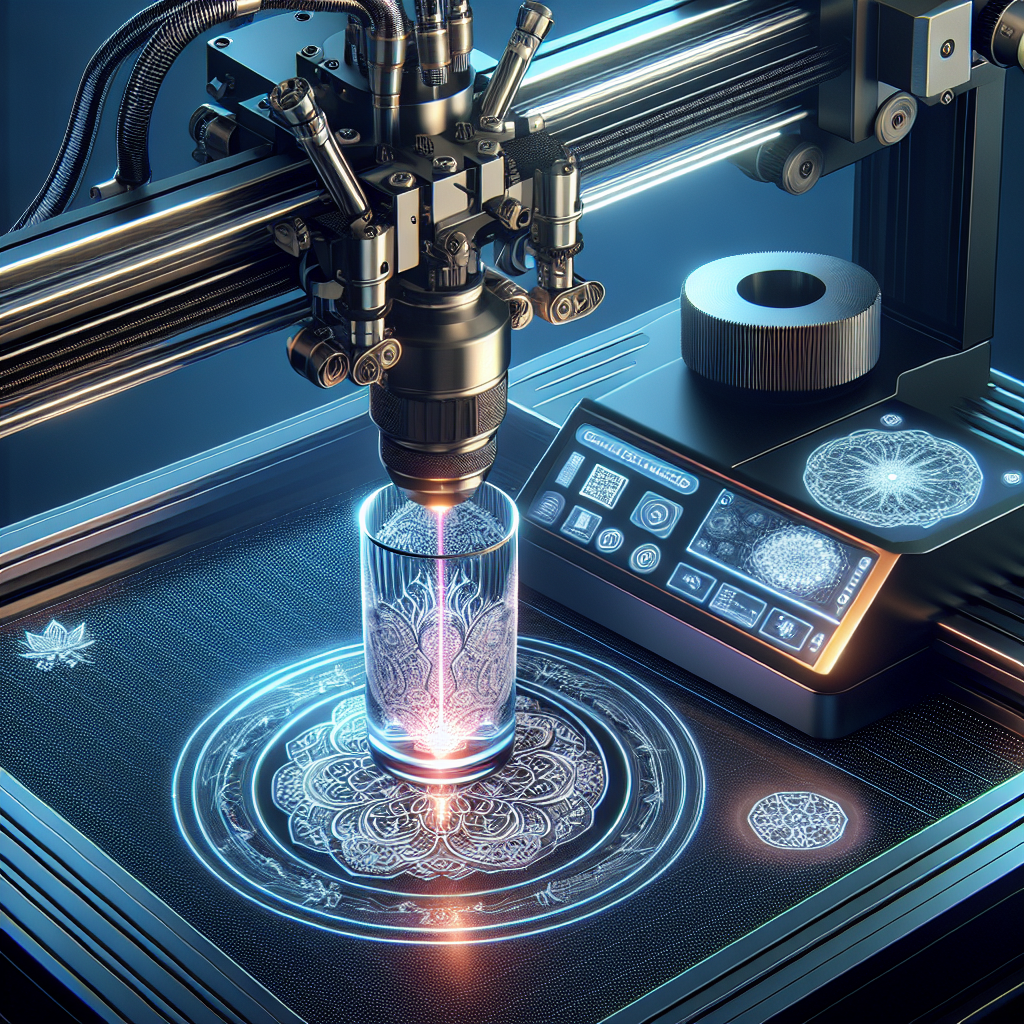

Laser engraving technology involves a concentrated beam of light to etch designs onto surfaces, celebrated for its precision and efficiency. Beyond tumblers, laser engraving machines are vital in sectors like automotive, electronics, and personalized gift production.

Interested in engraving tumblers? A laser engraving machine offers unmatched precision and control, enabling intricate designs that traditional methods can’t achieve. What sets the best laser for engraving tumblers apart? It emphasizes features and capabilities uniquely suited for cylindrical surfaces.

Machine Specifications and Features

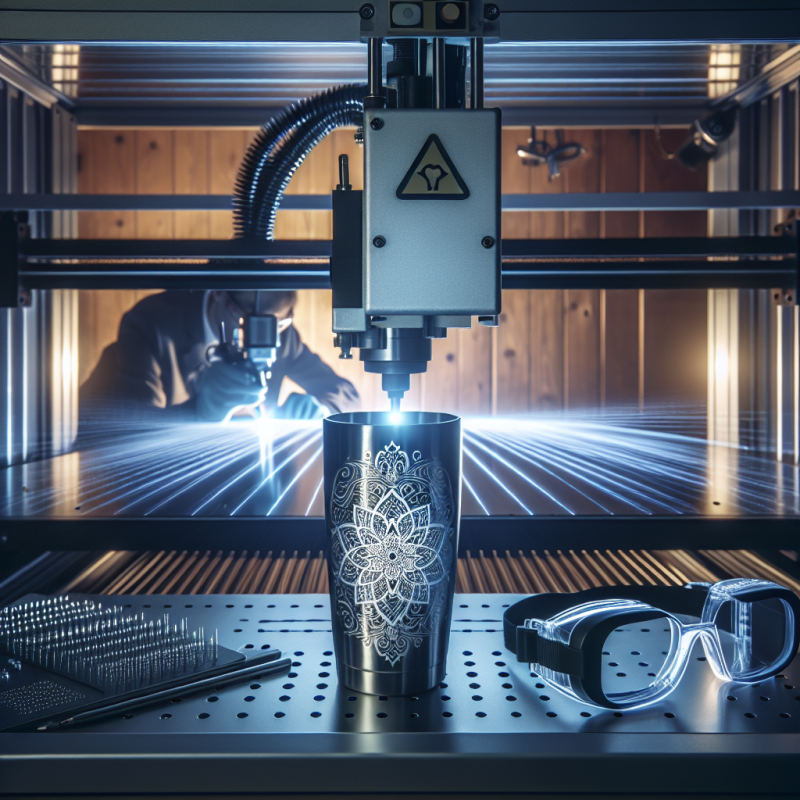

When seeking the best laser for engraving tumblers, machine specifications are crucial. Essential features include:

- Power Output: Higher wattage enables faster engraving and deeper cuts, crucial for specific materials.

- Engraving Area: A larger engraving area offers versatility, especially with varying tumbler sizes.

- Rotary Attachment: Essential for engraving cylindrical surfaces like tumblers, allowing object rotation during engraving.

- Software Compatibility: Intuitive software supporting various file formats streamlines your workflow.

Do these features guarantee that the machine is the best laser for engraving tumblers? Indeed, these specifications ensure superior-quality results.

Material Compatibility

The best laser for engraving tumblers should accommodate diverse materials, encompassing stainless steel, coated metals, and even plastic. Each material demands unique settings for optimal outcomes. For instance:

- Stainless Steel Tumblers: Generally require higher power settings for pronounced, clear engravings.

- Powder-Coated Tumblers: Often demand lower power settings to maintain the coating’s integrity.

- Plastic Tumblers: Need careful adjustments to avert melting or distortion.

Ensuring your laser engraver effectively handles these materials makes it the best laser for engraving tumblers.

Safety Considerations

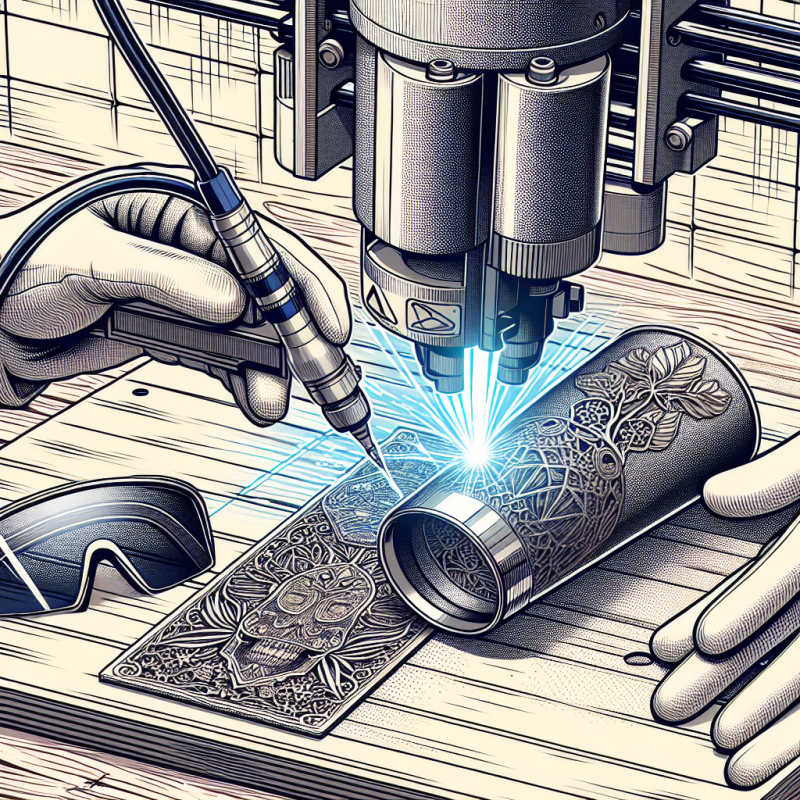

Safety should be a top priority when operating laser engraving machines. Key safety considerations include:

- Protective Gear: Always wear goggles or glasses that protect against laser exposure.

- Ventilation Systems: Ensure adequate ventilation to prevent inhalation of fumes during engraving.

- Regular Maintenance: Keep the machine clean and well-maintained to prevent malfunctions.

Do you prioritize safety when selecting the best laser for engraving tumblers? Implementing proper safety measures extends the machine’s lifespan while safeguarding health.

Industry Best Practices

Engraving tumblers involves adhering to industry best practices for exceptional outcomes:

- Pre-Test Designs: Test your designs on similar materials to avoid expensive mistakes.

- Regular Calibration: Regularly calibrate your laser engraving machine to maintain precision.

- Use Reliable Software: Ensure your software is dependable and up-to-date to prevent compatibility issues.

- Stay Informed: Stay updated with the latest advances in laser engraving technology.

Adhering to these best practices is essential when selecting the best laser for engraving tumblers, ensuring optimal performance and outcomes.

Cost-Benefit Analysis

Investing in the best laser for engraving tumblers represents a noteworthy financial undertaking. However, the advantages can far surpass the expenses:

- Increased Efficiency: Saves time with quicker, more precise engravings.

- Enhanced Quality: Delivers professional-grade engravings, potentially attracting more customers.

- Versatility: Capable of handling various materials, expanding your product offerings.

- Reduced Labor Costs: Automates numerous processes, reducing manual labor.

Do these factors affect your understanding of the financial implications of purchasing the best laser for engraving tumblers?

Maintenance Tips

Maintaining your laser engraving machine is vital for its longevity. Follow these maintenance tips for smooth operation:

- Regular Cleaning: Remove debris and dust to keep the machine efficient.

- Inspect Components: Regularly inspect belts, mirrors, and lenses for wear and tear.

- Lubricate Moving Parts: Regular lubrication of moving parts ensures smooth operation.

Are these maintenance tips helping you keep your best laser for engraving tumblers in peak condition?

Project Ideas and Tutorials

Once equipped with the best laser for engraving tumblers, unleash your creativity with these project ideas:

- Personalized Gifts: Create custom names and logos on tumblers.

- Corporate Branding: Design branded tumblers for corporate events or promotional merchandise.

- Artistic Designs: Experiment with intricate patterns and artwork.

Extensive tutorials are available online to guide you in maximizing your laser engraver’s potential, covering everything from beginner basics to advanced design tips.

Conclusion

Choosing the best laser for engraving tumblers involves evaluating factors such as technology, specifications, material compatibility, and safety. With the right knowledge and approach, you can achieve outstanding results, whether for personal projects or professional objectives. Equip yourself with this invaluable tool and explore the endless possibilities of laser engraving technology today.