Best Laser for Engraving Tumblers: Features, Top Choices, and More

Introduction

In recent years, the demand for personalized items, such as tumblers, has surged. This trend has opened up exciting opportunities for customization through laser engraving technology. Choosing the best laser for engraving tumblers is crucial to achieving stellar results and operational efficiency. With a wide range of laser engraving machines available today, knowing their features, specifications, and best practices is essential to making an informed decision. In this article, we delve into everything you need to know about selecting the perfect laser engraving machine for tumblers, ensuring you can enhance your projects and satisfy diverse user needs.

Understanding Laser Engraving Technology

Laser engraving is a non-contact, subtractive manufacturing technology that uses a high-powered laser beam to remove material from the surface of an object. This technique relies on precise control over laser movement and intensity, allowing for highly detailed and customizable designs. Whether for personal use, gifts, or commercial purposes, the ability to engrave tumblers attracts attention due to its durability and reduced risk of wearing off over time.

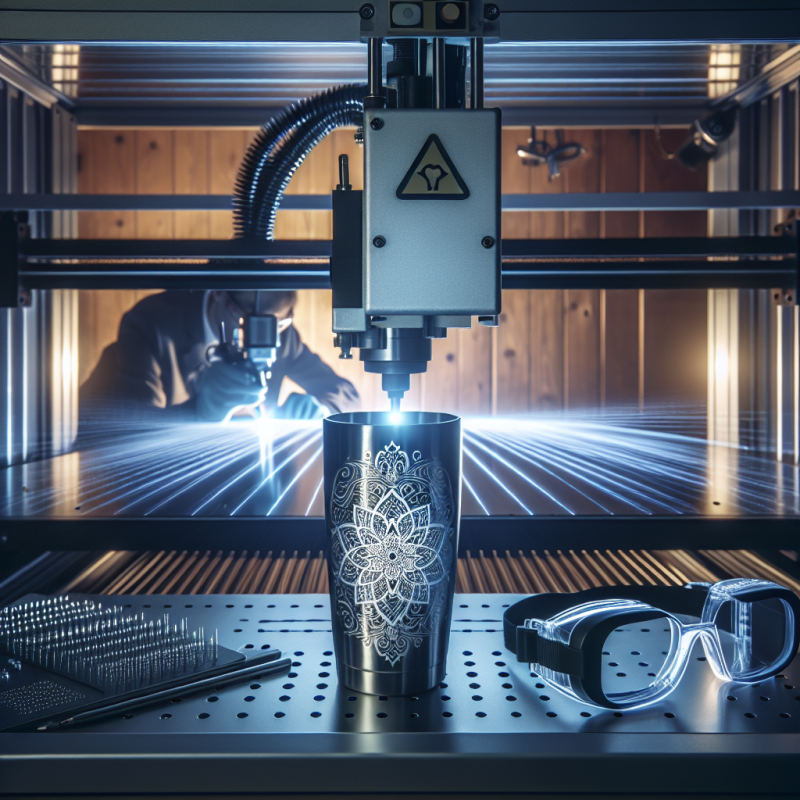

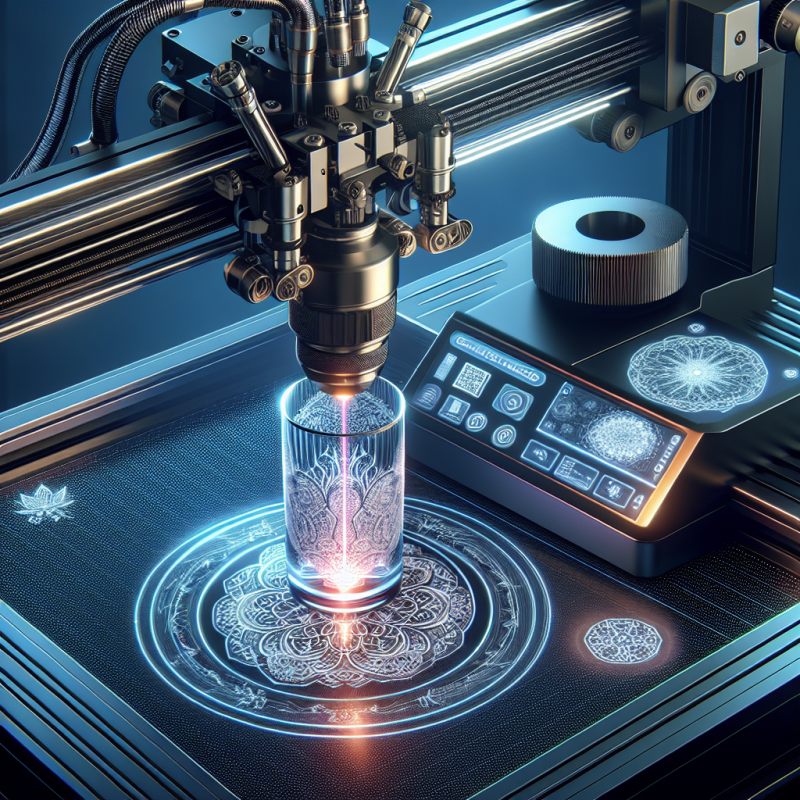

What makes a laser engraving machine suitable for tumblers is its ability to provide high-quality, consistent engravings with minimal setup. As technology advances, these machines have become more accessible to a broader audience, from hobbyists to industrial users. Selecting the best laser for engraving tumblers ensures you have access to the latest advancements, tailored for your specific needs.

Machine Specifications and Features

The choice of a laser engraver depends on several key specifications and features:

- **Power Output**: Essential for determining the materials and speed at which one can engrave. Higher power allows for working on harder materials with faster throughput.

- **Engraving Area**: Consider the size of the tumblers you intend to work with. Machines with larger engraving areas offer more flexibility for handling various sizes and shapes.

- **Focus and Beam Quality**: High-quality lenses and precise beam control contribute to finer details in the engravings.

- **Supported Materials**: It’s necessary to know what materials the laser can work on. Not all lasers are suitable for metals, plastics, and coated materials commonly found in tumblers.

- **Rotary Attachments**: For cylindrical items like tumblers, a rotary attachment is beneficial to maintain a steady design wrap.

- **Software Compatibility**: Modern machines should come with user-friendly software, allowing for easy design imports and adjustments.

Always consider these factors to ensure optimal performance and durability when selecting the best laser for engraving tumblers.

Material Compatibility

One of the most critical aspects of selecting the best laser for engraving tumblers is its compatibility with different materials. Tumblers can be made of various materials including stainless steel, aluminum, glass, and plastic, each requiring different engraving settings.

- *Metals*: Lasers with high power outputs are often needed for stainless steel and aluminum. Fiber lasers are particularly effective for metal engraving.

- *Glass*: CO2 lasers can provide beautiful matte finishes on glass surfaces.

- *Plastics*: Specialized settings and lasers ensure the material doesn’t burn or warp during the engraving process.

Ensuring material compatibility is vital for achieving the desired precision and avoiding damage to your tumblers.

Safety Considerations

Safety when operating laser engravers cannot be understated. Lasers pose potential risks, requiring operators to remain vigilant about safety measures:

- **Protective Gear**: Operators should wear appropriate eye protection to shield against harmful laser light exposure.

- **Ventilation**: Proper ventilation or extraction systems are needed to manage fumes emitted during the engraving process.

- **Training**: Adequate training ensures users understand both machine operations and emergency shutdown procedures.

- **Machine Maintenance**: Regular maintenance checks minimize the risks of malfunction and ensure safe operation.

Adhering to these safety measures helps create a safe working environment for both machines and users.

Cost-Benefit Analysis

Investing in the best laser for engraving tumblers represents a significant financial decision. Therefore, understanding the cost-benefit analysis is wise:

- **Initial Investment**: This includes the cost of purchasing the laser engraver and any additional attachments or software.

- **Operational Costs**: Consider the expenses related to power consumption, maintenance, and consumables.

- **Return on Investment (ROI)**: Evaluate how the machine will enhance productivity and potential revenue from customized tumbler sales.

Weighing these factors helps you assess whether the investment aligns with your business goals and customer demands.

Industry Best Practices

To maximize the efficiency and quality of your laser engraving projects, it’s important to adopt industry best practices:

- **Consistent Quality Checks**: Regularly inspect engraved products to maintain high quality standards.

- **Frequent Updates**: Keep software and firmware updated to access new features and improve machine performance.

- **Design Versatility**: Experiment with different designs and techniques to diversify your offerings and keep up with trends.

Following these practices not only boosts productivity but also ensures that customer satisfaction remains high.

Maintenance Tips

For your laser engraver to maintain its peak performance and longevity, consider the following maintenance tips:

- **Regular Cleaning**: Clean the laser lenses and mirrors to prevent buildup that can affect beam quality.

- **Check Alignments**: Ensure optical components are properly aligned for accurate engraving.

- **Lubrication**: Depending on your machine, some mechanical parts might need periodic lubrication.

- **Routine Inspections**: Conduct periodic checks to identify worn parts that require replacement.

Proper maintenance not only extends the lifespan of your machine but also reduces downtime, ensuring consistent operation.

Project Ideas and Tutorials

The versatility of laser engravers invites endless possibilities for creative projects. Here are some ideas to get started with your tumbler engraving adventures:

- *Custom Logos*: Engrave personalized brand logos for promotional items or corporate gifts.

- *Artwork and Patterns*: Experiment with intricate designs and patterns for artistic flair.

- *Celebrate Occasions*: Create themed engravings for birthdays, weddings, and holidays.

Tutorials available online can guide you through complex designs and projects, allowing you to master the nuances of laser engraving.

Conclusion

Choosing the best laser for engraving tumblers is a decision enhanced by a clear understanding of technology, machine features, material compatibility, and maintenance practices. Whether used for personalizations, creative endeavors, or expanding business offerings, these machines offer transformative capabilities. By integrating safety measures and industry best practices, you can ensure that your investment yields quality results and significant returns. Dive into the world of laser engraving with confidence and creativity, and redefine the way you approach tumbler personalization.