Best Laser for Engraving Tumblers: Precision & Style Guide

Introduction

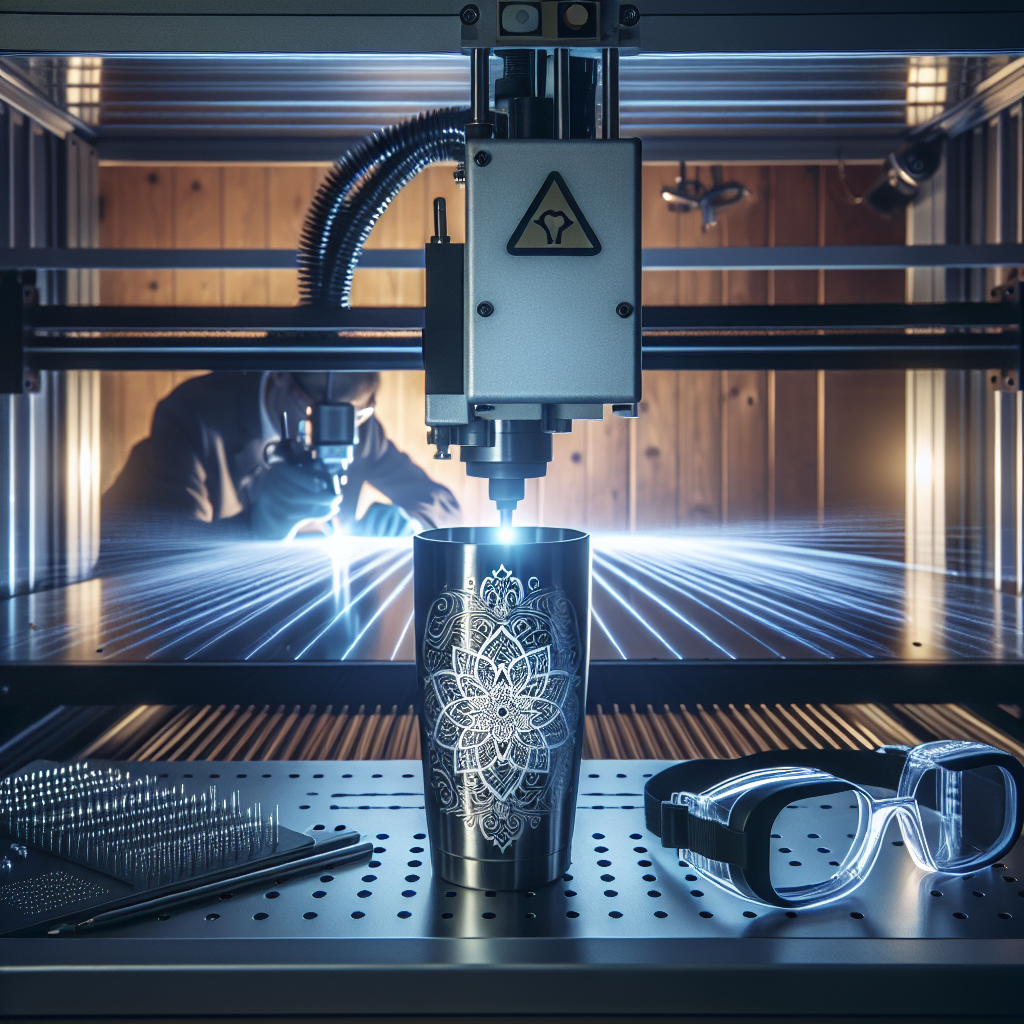

In the ever-expanding world of personalized products, customizing tumblers has become a popular trend. From corporate gifts to personal memorabilia, engraved tumblers make for a chic and functional choice. But what is the best laser for engraving tumblers? In this comprehensive guide, we delve into the intricacies of laser engraving technology, machine specifications, material compatibility, safety protocols, and more. Whether you’re starting a small business or expanding your creative craft, choosing the right laser engraving machine is critical.

Laser Engraving Technology and Applications

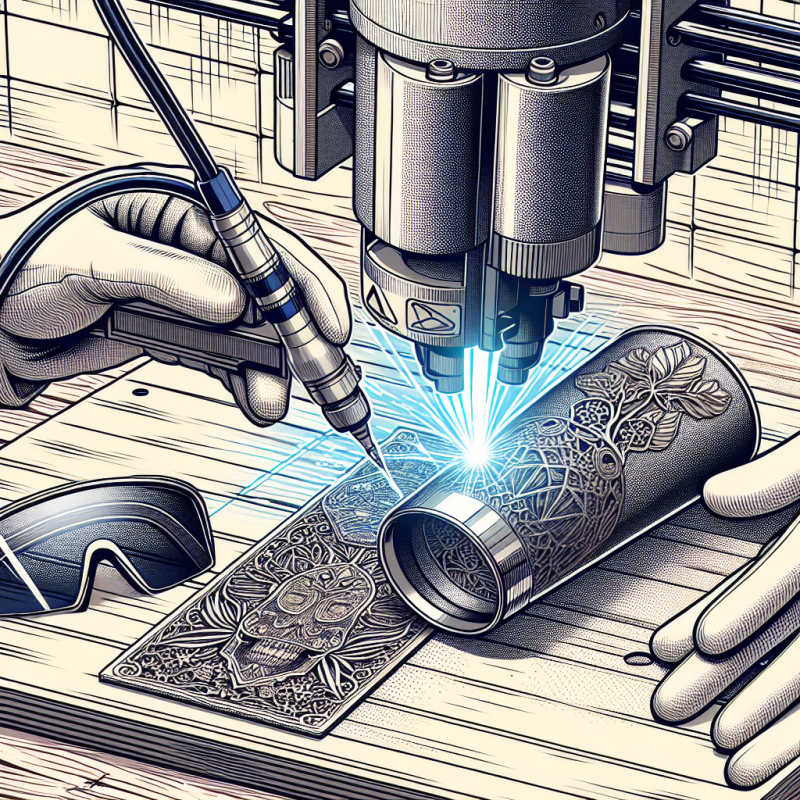

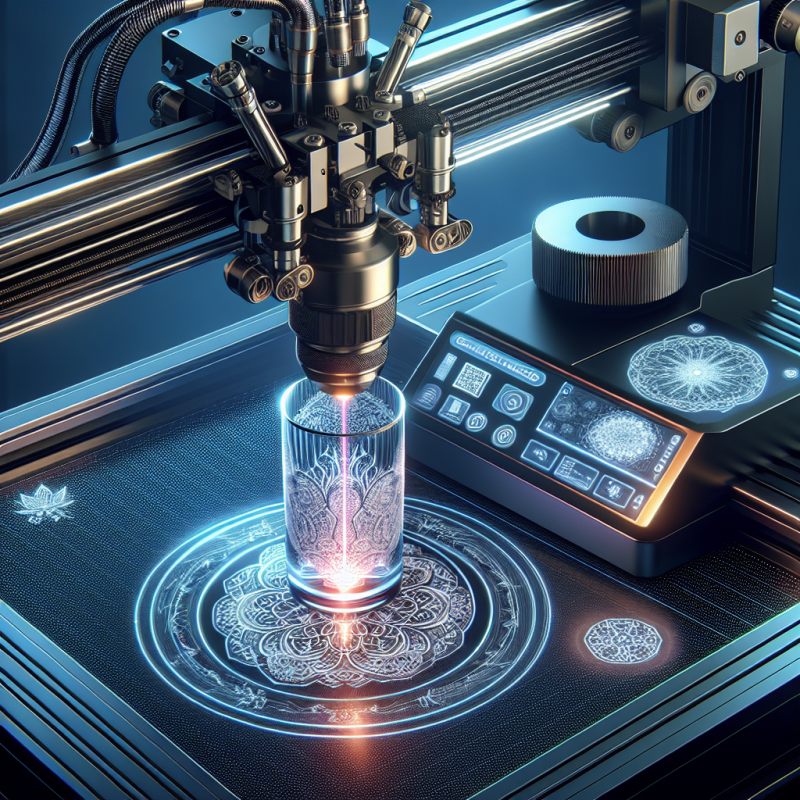

Laser engraving technology has revolutionized how we personalize items today. This precise method uses concentrated light beams to modify the surface of materials, creating permanent designs without physical contact. The best laser for engraving tumblers will offer features that facilitate intricate designs and patterns.

Applications are extensive, from etching simple logos to complex, photorealistic images directly onto the tumbler’s surface. This technology’s versatility extends across industries including retail, hospitality, promotional gifting, and even art projects.

Machine Specifications and Features

When determining the best laser for engraving tumblers, several core specifications and features should be considered:

- Laser Type and Power: CO2 lasers are popular due to their efficiency and ability to handle diverse materials. Look for a machine with adjustable power output, usually between 40 to 100 watts, for accuracy and depth control.

- Working Area: Depending on your production scale, the engraving area size is crucial. Larger beds allow for bulk processing, while smaller surfaces offer precision for detailed work.

- Software Compatibility: An engraving machine’s software should support various file formats and be user-friendly. It can enhance design capabilities and streamline operational workflow.

- Resolution and Speed: High DPI (dots per inch) and fast processing speeds are essential for intricate designs and efficient production rates.

- Cooling Systems: Effective air or water cooling systems can prevent the laser from overheating and maintain performance consistency.

Material Compatibility

One of the most vital aspects of selecting the best laser for engraving tumblers is ensuring it matches the material used. Tumblers are typically made from:

- Stainless Steel and Metal Alloys: These require higher-powered lasers and may need special coatings to engrave successfully.

- Plastic and Acrylic: Lower-power lasers work well, though ventilation is crucial to avoid harmful fumes.

- Glass: Laser etching can yield beautiful results with a frosted effect, but requires careful handling to avoid shattering.

Safety Considerations

Safety is paramount when operating laser engraving machines. Key safety aspects include:

- Eye Protection: Lasers can be harmful to your eyes, so always use certified protective eyewear.

- Ventilation: Ensure proper ventilation or fume extraction systems are in place to avoid inhalation of fumes generated during engraving.

- Machine Maintenance: Regularly check and maintain your machine to reduce the risk of malfunctions and potential hazards.

- Training: Comprehensive training on machine use and safety features is vital for all operators.

Industry Best Practices

Adopting industry best practices not only enhances safety but also ensures quality results. Start with material testing to determine the optimal settings. Document successful setups for consistency. Regularly clean the machine to prevent debris buildup, which can affect laser focus and operation.

Cost-Benefit Analysis

Understanding the cost versus benefit is crucial before investing in a laser engraving machine. Consider initial investments, including machine cost, installation, and training. Weigh them against long-term benefits such as increased efficiency, product diversification, and market competitiveness.

The best laser for engraving tumblers often proves a wise financial decision, especially when it opens new revenue streams through customizations that command premium prices.

Maintenance Tips

Proper maintenance extends the lifespan of your laser engraving machine. Here are essential tips:

- Regular Cleaning: Keep lenses, mirrors, and exhaust systems free from dust and debris.

- Scheduled Inspections: Perform professional inspections periodically to detect and rectify issues early.

- Software Updates: Stay updated with the latest software improvements for enhanced performance.

- Calibration: Regular calibration ensures the laser’s precision and accuracy over time.

Project Ideas and Tutorials

Unleash creativity with project ideas such as personalized wedding party tumblers, corporate-branded gifts, or custom art pieces. Seek out tutorials that match the capabilities of the best laser for engraving tumblers, enhancing both skill and output variety.

Questions to Consider:

- What are the specific power settings required for different materials when using a laser engraving machine?

- How can one ensure the safety of operators and the environment while using such a machine?

- What are the long-term benefits of investing in the best laser for engraving tumblers?

- What are some innovative designs or applications one can explore with laser-engraved tumblers?