CNC and Laser Cutter Machines: Revolutionizing Precision Manufacturing

Laser engraving machines and cnc or laser cutter systems have transformed industries by enabling unparalleled precision, speed, and versatility. Whether you’re crafting intricate designs or mass-producing components, these technologies offer solutions that traditional tools simply cannot match. This article dives deep into the mechanics, applications, and advantages of modern cnc or laser cutter systems, while addressing common questions and industry trends.

Understanding CNC and Laser Cutting Technology

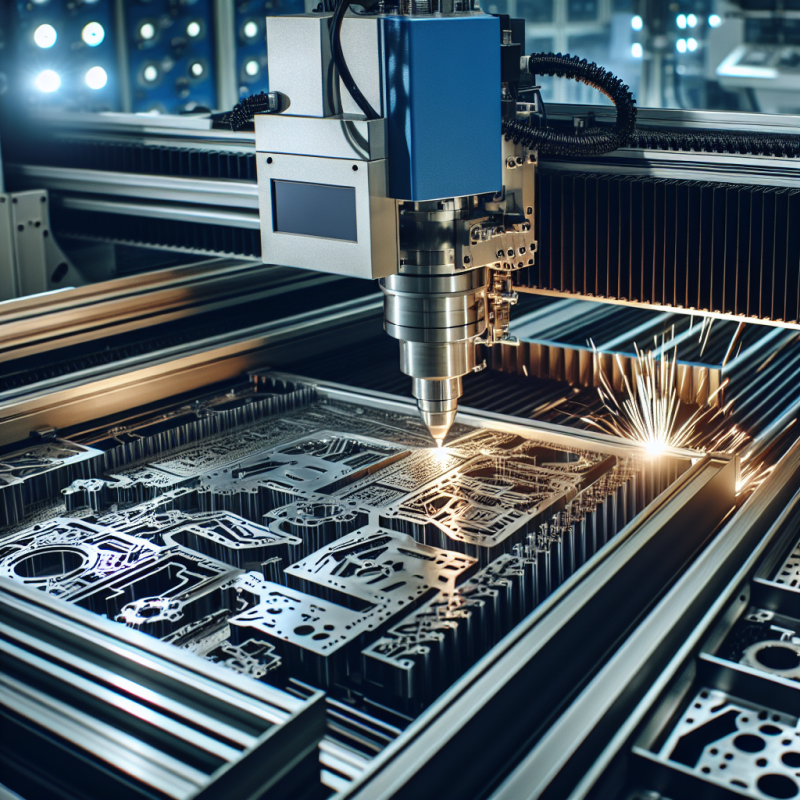

At the core of modern fabrication lies Computer Numerical Control (CNC), a technology that automates machine tools via programmed commands. When combined with laser cutting, this synergy creates a cnc or laser cutter machine capable of executing complex tasks with micron-level accuracy. These systems use high-powered lasers to melt, burn, or vaporize materials, guided by CAD/CAM software to achieve precise cuts or engravings. Why is this combination so powerful? Because it merges the repeatability of CNC with the flexibility of laser technology.

Key Advantages of CNC Laser Engraving Machines

The benefits of using a cnc or laser cutter system are numerous:

- Precision: Lasers can achieve cuts as fine as 0.1mm, ideal for detailed artwork or engineering components.

- Speed: Automated processes reduce production time by up to 70% compared to manual methods.

- Material Versatility: From metals and plastics to wood and glass, these machines handle diverse substrates.

- Cost Efficiency: Reduced waste and lower labor costs make them ideal for large-scale operations.

Did you know? Advanced models like the Hawk S1 CNC Laser Cutter integrate AI-driven adjustments to optimize energy use and minimize errors.

Applications Across Industries

cnc or laser cutter machines are indispensable in sectors such as:

- Aerospace: Cutting lightweight alloys for aircraft components.

- Automotive: Engraving serial numbers or crafting custom interiors.

- Jewelry: Creating intricate patterns on precious metals.

- Healthcare: Manufacturing surgical tools with sterile, burr-free edges.

What’s next for these technologies? Emerging trends include hybrid systems that combine 3D printing with laser engraving for multi-stage prototyping.

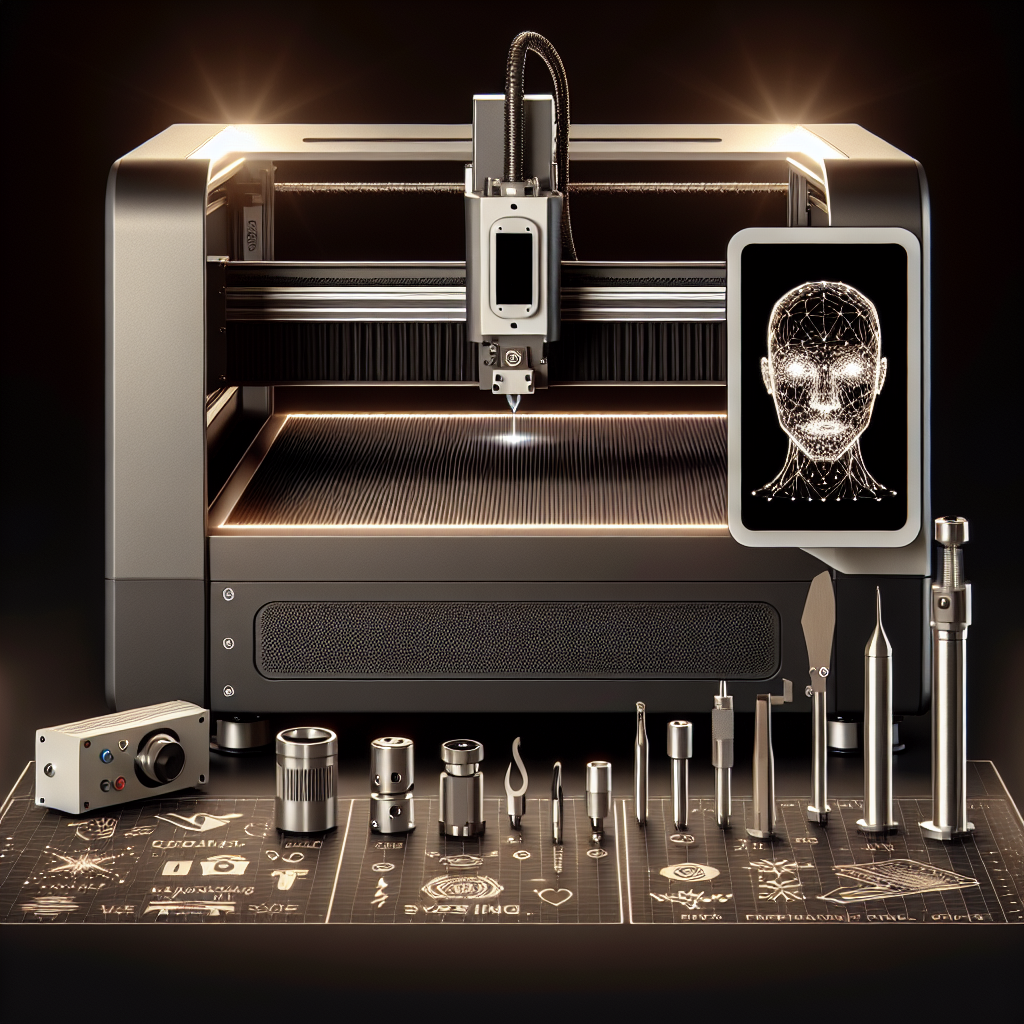

Choosing the Right Machine for Your Needs

Selecting a cnc or laser cutter requires careful consideration:

- Power Output: Higher wattage (e.g., 100W+) suits metal cutting, while 40-60W lasers work for wood and acrylic.

- Work Area Size: Match the machine’s bed dimensions to your largest projects.

- Software Compatibility: Ensure compatibility with industry-standard programs like AutoCAD or CorelDRAW.

- Safety Features: Look for enclosed designs, emergency stops, and fume extraction systems.

Pro Tip: The Hawk S1 CNC Laser Cutter excels in balancing power and affordability, making it a favorite among small-to-medium enterprises.

Maintenance and Safety Best Practices

To maximize the lifespan of your cnc or laser cutter machine:

- Clean lenses and mirrors weekly to maintain beam quality.

- Calibrate the CNC axis alignment monthly.

- Use only manufacturer-approved replacement parts.

- Train operators in laser safety protocols, including protective eyewear.

Question: How often should you replace the laser tube? Most CO2 tubes last 2,000-5,000 hours, depending on usage intensity.

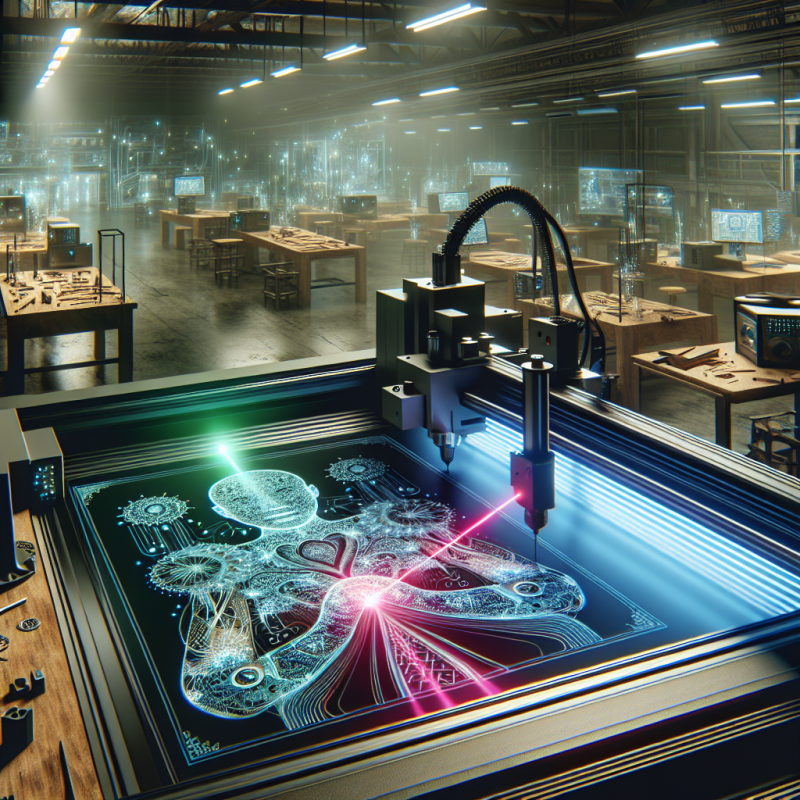

The Future of Laser Engraving Technology

Innovations in cnc or laser cutter systems are accelerating:

- Femtosecond Lasers: Ultra-short pulses for nanoscale precision in semiconductor manufacturing.

- Green Lasers: Improved efficiency for processing copper and other reflective materials.

- IoT Integration: Real-time monitoring via cloud-based platforms to predict maintenance needs.

Fun Fact: Researchers are experimenting with laser-based additive manufacturing to build structures in zero-gravity environments!

Common Questions About CNC Laser Machines

Q: Can a cnc or laser cutter handle curved surfaces?

A: Yes, with rotary attachments, cylindrical objects like bottles can be engraved seamlessly.

Q: What’s the main difference between CO2 and fiber lasers?

A: CO2 lasers are better for organic materials, while fiber lasers excel at metals and engineered plastics.

Q: How much ventilation does a laser cutter require?

A: Always operate in well-ventilated areas or use integrated exhaust systems to remove toxic fumes.

Conclusion

The evolution of cnc or laser cutter technology continues to redefine manufacturing possibilities. Whether you’re a hobbyist exploring creative projects or an industrial engineer optimizing production lines, these machines offer unmatched precision and adaptability. As innovations like AI and IoT reshape the landscape, investing in robust systems like the Hawk S1 CNC Laser Cutter ensures you stay ahead in this competitive field. Ready to harness the power of laser engraving? The future is bright—and precisely etched.