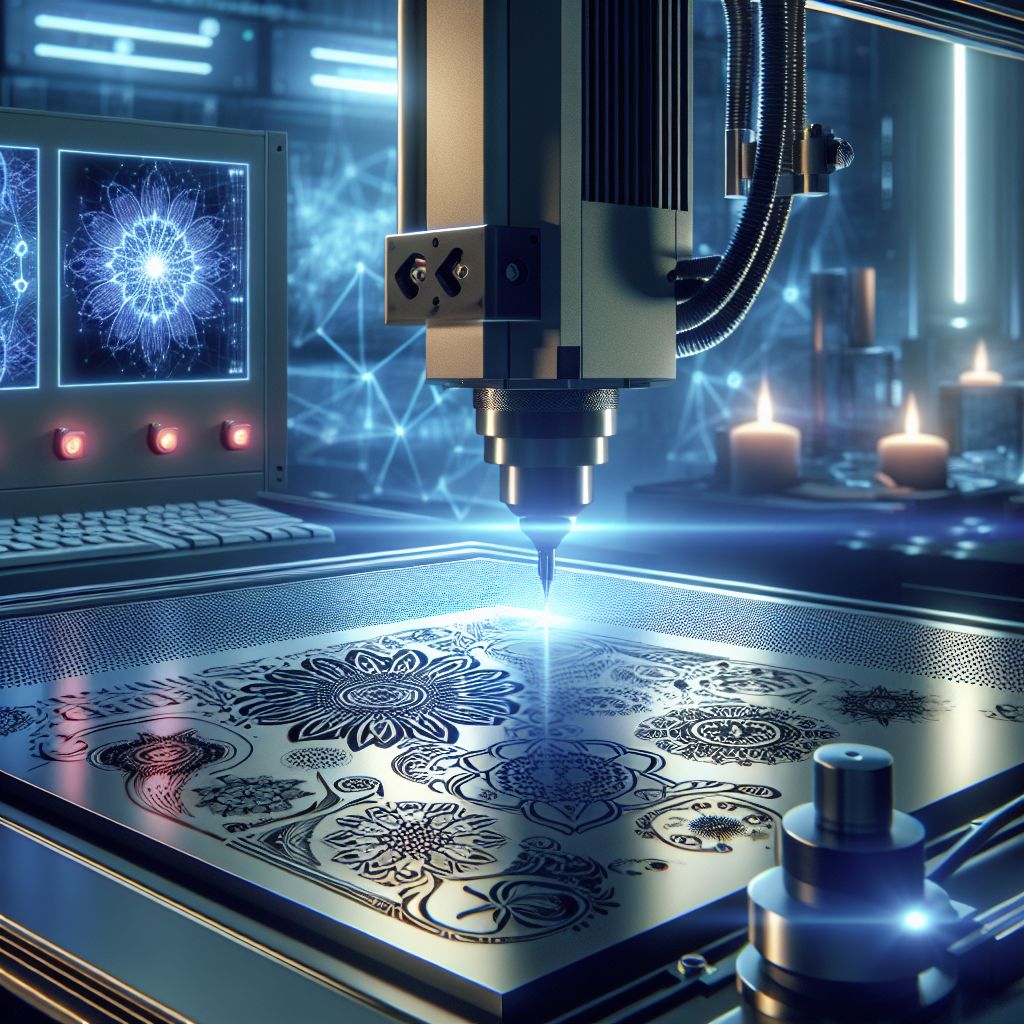

Title: Color Laser Marking Machine: Precision & Versatility

Introduction

Incorporating the latest advancements in laser technology, color laser marking machines have revolutionized the way businesses and hobbyists approach engraving projects. From creating personalized gifts to marking industrial components, these machines offer unparalleled versatility and precision. In this article, we delve into the details of color laser marking machines, exploring their technology, applications, specifications, and more.

Laser Engraving Technology and Applications

At the heart of any laser engraving device is its laser technology, which involves the use of highly focused beams of light to alter the surface properties of materials. Unlike traditional mechanical engraving methods, laser engraving offers non-contact, wear-free processing that ensures high precision and repeatability. The versatility of color laser marking machines is evident in their diverse applications:

- Personalized Products – Engrave names, logos, or messages on items like jewelry, phone cases, and other personal items.

- Industrial Marking – Used for part identification, traceability, and branding in sectors like aerospace and automotive.

- Medical Devices – Create precise, tamper-proof markings crucial for compliance with regulatory standards.

- Artistic Creations – Ideal for artists and designers to create intricate patterns and vibrant designs.

These widespread applications highlight why color laser marking machines are an attractive choice for a broad range of projects.

Machine Specifications and Features

Understanding the specifications and features of any color laser marking machine is crucial to leveraging its full potential. Some of the common features include:

- Wavelength and Power – The ability to adjust these allows for precise control over marking depth and color composition.

- Resolution and Speed – High DPI (dots per inch) ensures detailed engravings, while adjustable speed optimizes both performance and output quality.

- Software Compatibility – User-friendly software supports various file formats and design interfaces, providing additional creative freedom.

- Size and Weight – Compact designs of desktop units make them suitable for small workshop spaces, whereas larger industrial models cater to high-volume production.

These characteristics can significantly affect your engraving needs.

Material Compatibility

The adaptability of color laser marking machines is partly due to their compatibility with an extensive range of materials, including:

- Metals – Such as aluminum, brass, copper, and stainless steel, often used in industrial marking.

- Plastics – Including ABS, polycarbonate, and acrylic, allowing for custom engravings on consumer products.

- Wood – Perfect for crafting custom signs, gift items, and artistic projects.

- Glass and Ceramics – Create elegant designs without compromising material integrity.

Understanding material compatibility is vital to achieving the desired results with a color laser marking machine.

Safety Considerations

Operating any advanced machinery brings inherent risks, and it is important to adhere to safety protocols while using a color laser marking machine. Key safety measures include:

- Protective Gear – Use laser safety glasses rated for the specific wavelength of the machine.

- Ventilation – Ensure an adequately ventilated area to prevent inhalation of fumes generated during engraving.

- Emergency Shutoff – Machines should be equipped with accessible emergency stops to halt operation promptly if needed.

- Regular Maintenance – Routine checks and maintenance reduce the risk of unexpected malfunctions.

It’s crucial to implement these safety precautions for effective operation.

Industry Best Practices

The use of color laser marking machines is guided by several best practices that optimize efficiency and output quality:

- Proper Setup – Ensure the machine is located on a stable surface and connected correctly to the power supply.

- Calibration – Regular calibration of the laser beam improves accuracy and consistency of the engravings.

- Testing – Conduct test runs on sample materials to fine-tune settings before beginning a large batch.

- Training – Users should be adequately trained to handle the machine and its software effectively.

These best practices can significantly enhance the performance of a color laser marking machine.

Cost-Benefit Analysis

Investing in a color laser marking machine involves analyzing the costs against anticipated benefits. The initial purchase cost might be significant, but the advantages include:

- High Precision – Enables the creation of intricate designs that enhance product value.

- Versatility – Reduces the need for multiple machines by catering to various materials and applications.

- Efficiency – Increases production rates due to high-speed marking capability.

- Low Operating Costs – Minimal maintenance and consumable requirements lead to long-term savings.

The value of an investment in a color laser marking machine should not be underestimated.

Maintenance Tips

To prolong the lifespan and performance of a color laser marking machine, routine maintenance is indispensable. Here are tips to maintain its optimal operation:

- Regular Cleaning – Remove dust and debris from the laser head and lenses using appropriate cleaning tools.

- Software Updates – Keep your software and firmware up to date to benefit from the latest functionalities.

- System Checks – Periodically inspect electrical and mechanical components to identify signs of wear or damage.

- Professional Servicing – Engage with professionals for thorough servicing to maintain peak performance.

Regular maintenance ensures reliability in a color laser marking machine’s operation.

Project Ideas and Tutorials

Leveraging the power of a color laser marking machine can bring creative visions to life. Consider these project ideas and available tutorials:

- Customized Gifts – Engrave ornaments, notebooks, and leather goods with personal messages or designs.

- DIY Home Décor – Create wall art, coasters, and engraved glassware for a unique touch.

- Educational Projects – Use tutorials to explore various engraving techniques and methods on different substrates.

- Prototype Development – Test designs and functionalities on new products without the need for mass production.

The potential projects with a color laser marking machine can inspire endless creativity.

In conclusion, color laser marking machines offer unmatched precision and versatility, making them an invaluable asset for anyone looking to elevate their engraving projects. By understanding their features, applications, and best practices, users can maximize the value of their investment and unlock endless creative possibilities.