Discover the Power of Precision: Exploring the Best Laser Marking Machine

Introduction

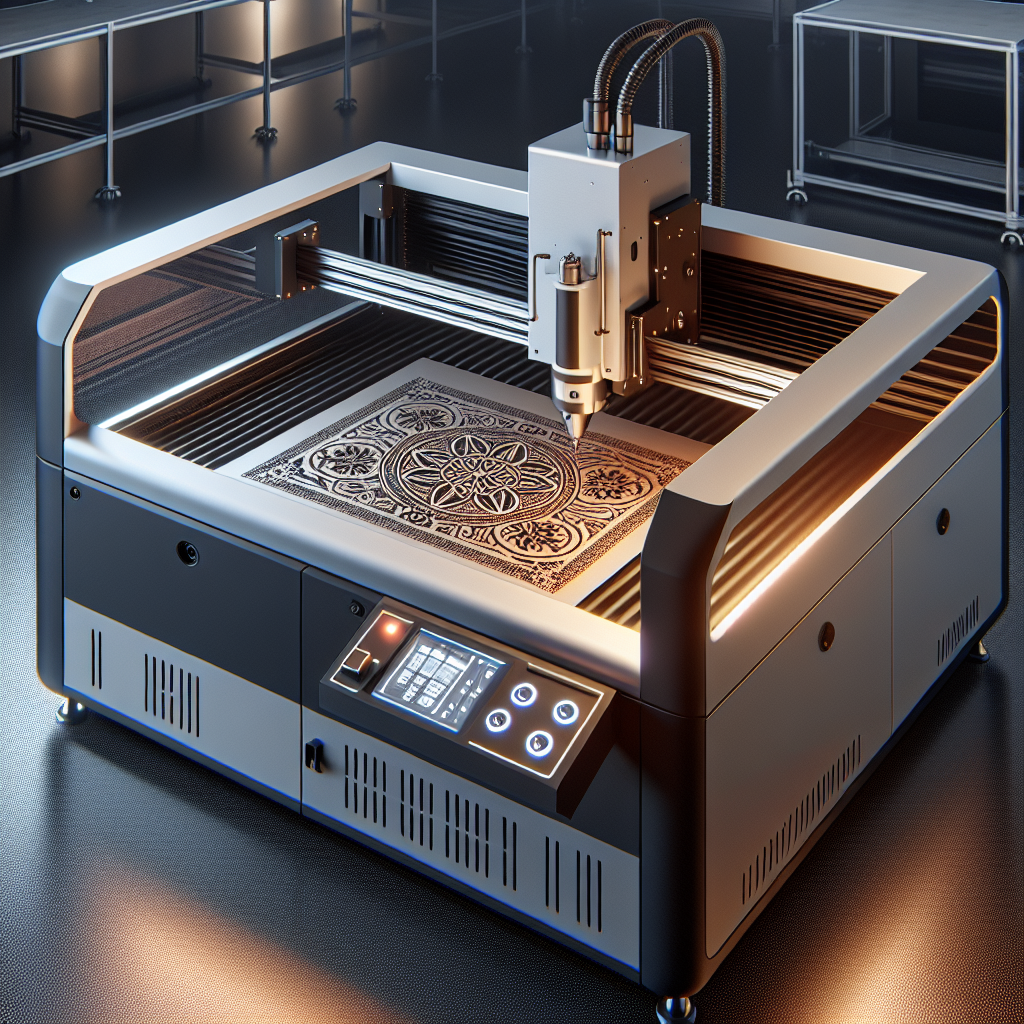

In the fast-evolving world of technology, laser engraving machines have become an indispensable tool for artists, manufacturers, and hobbyists alike. The demand for the best laser marking machine continues to grow, primarily driven by its exceptional accuracy, versatility, and efficiency in handling a variety of tasks. In this article, we delve into the nuances of laser marking machines, focusing on their technology, applications, specifications, and much more.

Understanding Laser Engraving Technology

Laser engraving involves the use of high-powered lasers to etch designs onto a wide range of materials. These machines work by directing the laser beam across the surface, vaporizing the material to reveal the desired design. This process is not only precise but also repeatable, making it perfect for both single-use and mass production applications.

One of the standout machines in this category is the best laser marking machine, known for its reliable performance and high precision. But what makes laser engraving technology so sought after?

- Precision: Achieve intricate designs with unparalleled accuracy.

- Versatility: Compatible with a variety of materials like wood, metal, glass, and plastic.

- Speed: Rapid processing time for increased productivity.

- Consistency: Uniform quality in every engraving project.

Machine Specifications and Features

Choosing the best laser marking machine often boils down to understanding its specifications and features. Let’s take a closer look at what makes a great machine:

Laser Power and Type: The power of the laser determines the types of materials it can effectively engrave. Diode lasers, CO2 lasers, and fiber lasers all provide different capabilities suited for varied applications.

Engraving Speed: For those needing fast turnaround times, a higher speed machine is often more desirable.

Engraving Area: The maximum area that a laser marking machine can work on plays a critical role, especially for larger projects.

User Interface: Intuitive software allows for easier design and execution, enabling users to get the most out of their machine.

Best laser marking machines are also often equipped with additional features such as a protective enclosure and advanced cooling systems to maintain the best operational conditions.

Material Compatibility

Not every laser engraving machine can handle all types of materials. Understanding the material compatibility is crucial:

- Metals: Stainless steel, aluminum, and other metals require specific laser types for effective marking.

- Wood: Softwoods engrave more easily than hardwoods and produce contrasting designs.

- Plastics: Certain plastics may require specific wavelengths for deep markings.

- Glass and ceramics: Require careful handling to prevent cracking or breaking during engraving.

Safety Considerations

The usage of lasers can pose safety risks. It’s important to follow industry best practices to ensure safe operation:

Enclosures: Machines like the best laser marking machine often come with enclosures to contain stray beams.

Protective Gear: Wearing laser safety glasses and protective clothing can prevent accidents.

Ventilation: Always work in well-ventilated areas to avoid inhaling fumes generated during engraving.

Industry Best Practices

Maximizing the use of laser marking machines involves understanding and implementing industry best practices:

Regular Maintenance: Routine checks help in prolonging the life of the machine and avert potential breakdowns. Proper maintenance ensures the laser cutter’s components remain in optimal working condition.

Software Updates: Keeping engraving software up-to-date can introduce new features and improve performance.

Training: Both new and seasoned users should undergo regular training to stay abreast of the latest techniques and technologies.

Cost-Benefit Analysis

Investing in a best laser marking machine can seem daunting, but the benefits often outweigh the costs:

- Initial Investment: Quality machines may have a high upfront cost but provide excellent ROI over time.

- Reduced Labor Costs: Automation reduces the need for manual labor, leading to savings.

- Increased Productivity: Faster turnarounds help businesses meet high demand efficiently.

- Opportunities for Customization: Expand offerings with personalized products that command higher prices.

Maintenance Tips

Regular maintenance is integral to ensuring your laser engraving machine runs smoothly:

Cleaning: Regularly clean lens and mirrors to prevent dust accumulation that can impair laser performance.

Calibration: Periodically calibrate the machine to maintain precision and alignments.

Component Checks: Regularly inspect vital components like belts and motors to spot wear and tear early.

Project Ideas and Tutorials

The creative possibilities with a laser engraving machine are endless. If you’re on the fence about investing in one, consider these potential projects:

- Custom Jewelry: Create intricate designs on metal or wood-based jewelry.

- Personalized Gifts: Engraved plaques, cutting boards, and coasters make for delightful personalized gifts.

- Home Décor: Lights, picture frames, and wall art created using laser engravings can transform a space.

- Educational Tools: Schools and educators can design custom learning aids and tactile teaching tools.

Conclusion

The allure of using a best laser marking machine is undeniable, with its potential for precision, efficiency, and creativity. By considering the specifications, materials, safety, and maintenance tips outlined in this article, you can make an informed decision. Whether you’re a professional engraver or a hobbyist exploring new avenues, the right choice can transform your projects and enhance your capabilities. Dive into the world of laser engraving, where the only limit is your imagination.