Title: Discovering Laser Engraving Machines in Australia

Introduction

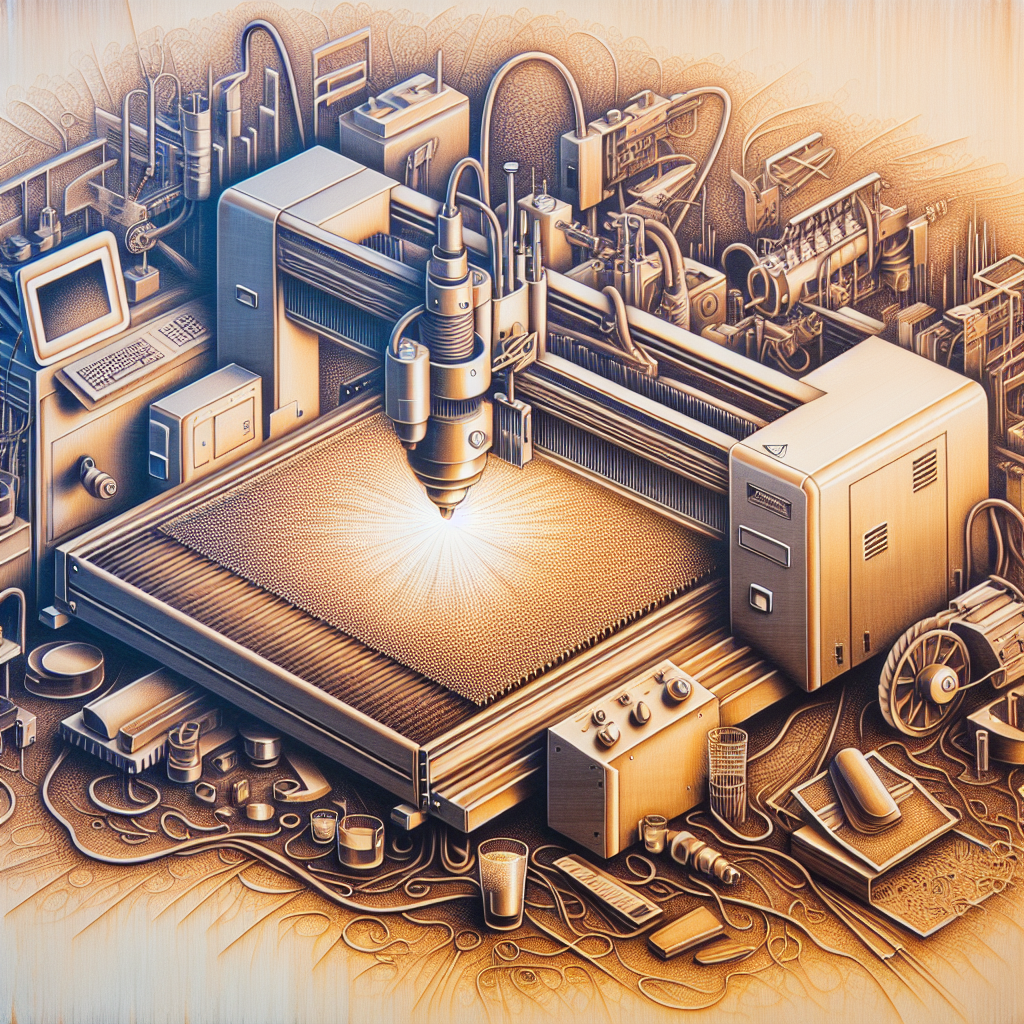

In recent years, the popularity of laser engraving machines in Australia has skyrocketed. This technology has become indispensable for artists, entrepreneurs, industrial applications, and hobbyists alike. But what makes laser engraving machines so versatile and appealing? This article delves into the intricate workings of these machines, exploring their technology, diverse applications, and key considerations when investing in one.

Laser Engraving Technology and Applications

At the heart of laser engraving machines lies advanced laser technology that ensures pinpoint precision and consistency. These machines use a laser beam to engrave patterns, images, and text onto various materials without physical contact. The ability of a laser engraving machine in Australia to achieve detailed designs is exceptional, making it a preferred tool among jewelers, marketers, and manufacturers.

Laser engraving is widely used across diverse industries, such as automotive, aerospace, electronics, textiles, and even medical devices. The technology is ideal for personalization, mass production, and intricate customization. Beyond industrial applications, laser engravers are increasingly becoming a staple in homes and small workshops for creating personalized gifts and engaging in creative projects.

Machine Specifications and Features

When selecting a laser engraving machine in Australia, understanding the specifications is crucial. Consider the following aspects:

- Power Output: Higher wattage often results in faster engraving on tougher materials.

- Engraving Area: Determines the maximum size of the object you can engrave.

- Resolution Capabilities: Measured in DPI (Dots Per Inch), impacting the achievable detail level.

- Software Compatibility: Important for design importation and machine control.

- Connectivity: Options like USB, WiFi, and Ethernet offer flexible interfacing.

Material Compatibility

A laser engraving machine in Australia should be compatible with various materials to justify the investment. Commonly used materials include:

- Wood

- Acrylic

- Metal

- Glass

- Leather

- Paper and Cardboard

The key is selecting a machine that suits your primary material requirements, as material changes affect the laser setting and engraving speed. Consider these factors carefully to ensure optimal performance across different projects.

Safety Considerations

Operating a laser engraving machine in Australia is generally safe, but adherence to safety protocols is vital to ensure user safety.

- Laser Safety Glasses: Essential for protecting your eyes from harmful laser beams.

- Ventilation: Ensure proper ventilation to avoid inhaling fumes from burned materials.

- Machine Enclosure: Enclosures prevent accidental exposure to laser beams.

- Emergency Stop Button: Vital for ceasing operations immediately during unexpected occurrences.

Industry Best Practices

For optimal performance, adhere to industry best practices when using a laser engraving machine in Australia:

- Regularly clean the laser lens and mirrors to ensure clarity and precision.

- Adhere to manufacturer’s guidelines for power settings and speed to prolong machine life.

- Experiment with different settings on scrap materials first to fine-tune your engravings for the best results.

Cost-Benefit Analysis

Purchasing a laser engraving machine in Australia is a significant investment. The upfront cost is only one part of the equation; ongoing operational and maintenance costs also require consideration. Nevertheless, the benefits of having a versatile tool that can save time and expand creative possibilities often outweigh the challenges.

Evaluating the demand for engraved products and anticipated business growth or hobby expansion can help justify the investment. In many cases, businesses quickly recoup their expenses through increased efficiency and expanded product offerings, making the investment worthwhile.

Maintenance Tips

Consistent upkeep of a laser engraving machine in Australia is essential for longevity and performance. Some tips include:

- Regularly clean the lens and mirrors to ensure they remain free from debris and residue.

- Check and adjust the laser’s alignment as needed for precision.

- Lubricate moving parts periodically to reduce wear and tear.

- Perform routine software updates for better functionality and enhanced performance.

Project Ideas and Tutorials

Owning a laser engraving machine in Australia opens up a world of creativity and opportunity. Here are some project ideas you can explore:

- Custom phone cases

- Personalized trophies and awards

- Intricate jewelry designs

- Decorative wall art

- Customized kitchenware

Many resources and tutorials are available online to help beginners start their laser engraving journey, catering to both personal projects and commercial ventures. These can help spark creativity and expand the utility of your machine.

Conclusion

The potential of laser engraving machines is vast, making them a worthwhile investment for a variety of applications. By understanding the technology, machine specifications, and ensuring safety and best practices, you can leverage the full capabilities of these powerful devices. Whether you’re in Australia or elsewhere, a laser engraving machine in Australia can transform your creative visions into reality, offering both aesthetic appeal and practical functionality.