Title: Enhance Precision with a CNC Glass Cutting Machine

Introduction

In today’s rapidly advancing technological landscape, the rise of laser engraving machines has opened up numerous possibilities for creators, hobbyists, and industry veterans alike. Central to this revolution is the cnc glass cutting machine, a tool that transforms mere ideas into tangible creations with remarkable precision. This article explores the intricacies of laser engraving technology, focusing particularly on the transformative potential of the LaserPecker LP5.

Understanding Laser Engraving Technology

Laser engraving technology operates on a fundamental principle—using laser beams to engrave or cut materials. This precise control facilitates intricate designs and cutting without the risk of physical contact or wear that traditional tools encounter. The applications are diverse, spanning personalized gifts, jewelry, signage, and complex industrial projects. What truly sets the cnc glass cutting machine apart is its adaptability and efficiency in working with various materials, making it a versatile choice for many users.

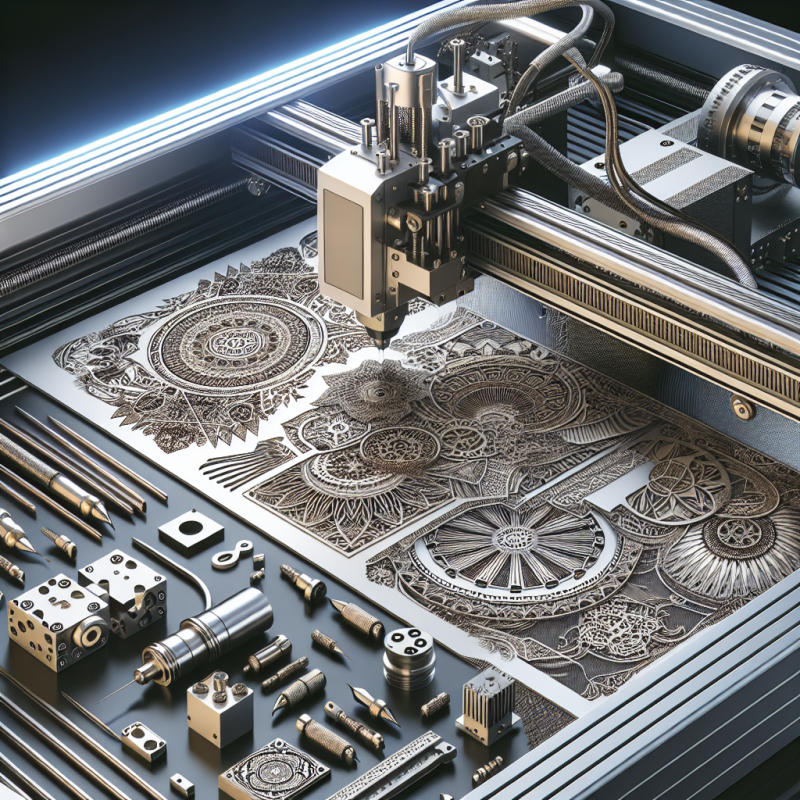

Key Specifications and Features of the LaserPecker LP5

The LaserPecker LP5 is a cutting-edge tool in the realm of laser engraving, featuring a powerful 20W fiber diode laser that ensures high-speed engraving with unmatched precision. Among its standout features are a compact size, smart app control, and a robust build that enhances the user experience. The LP5 is designed for scalability, allowing users to tackle larger projects with ease, thanks to its expandable platform and adjustable focus settings.

In addition, the impressive speed and accuracy of the LP5 enable it to undertake high-resolution engraving projects effortlessly. With smart software, users can experience seamless integration with design programs, allowing for a smooth transition from concept to creation. These specifications position the cnc glass cutting machine as a key player in the realm of creative innovation.

Material Compatibility and Versatility

When selecting a laser engraving machine, material compatibility is critical. The LaserPecker LP5 excels in this domain, offering exceptional flexibility. It can handle a wide range of materials, including wood, leather, metal, and, as its name indicates, glass. This versatility enables users to experiment with different textures and finishes. Whether crafting delicate pieces of art or producing durable industrial components, the cnc glass cutting machine is equipped to meet the challenge.

Safety Considerations in Laser Engraving

With the power and precision of laser engraving comes the necessity for vigilant safety considerations. It is essential to recognize the potential hazards associated with laser technology, especially when engaging with materials that may be hazardous. The LaserPecker LP5 effectively addresses safety, equipped with a protective shield and safety goggles that minimize exposure to harmful laser light. Furthermore, the machine’s design incorporates automatic shut-off mechanisms during anomalies, underscoring that user safety is always a priority.

Industry Best Practices for Laser Engraving

What defines best practices in laser engraving? Proper machine handling and adherence to safety protocols are crucial. Users should ensure the laser path is clear of obstructions and that the machine is calibrated correctly for the material being used. Additionally, regular maintenance—such as cleaning lenses and mirrors—can significantly prolong the life and efficiency of the cnc glass cutting machine.

Cost-Benefit Analysis of the LaserPecker LP5

Investing in a laser engraving machine necessitates weighing costs against benefits. Although the initial investment may be considerable, the versatility and efficiency of machines like the LaserPecker LP5 offer significant long-term savings. This tool helps reduce material waste due to its precision and lower labor costs by automating intricate processes. Moreover, the potential for personalized and unique creations greatly expands business opportunities, making the investment in a cnc glass cutting machine a prudent choice.

Maintenance Tips for Optimal Performance

To ensure longevity and optimal performance, routine maintenance is essential. Regular checks and cleaning, particularly of optical elements like lenses and mirrors, help maintain precision. Keeping the machine’s firmware updated enhances performance and introduces new features. Users should perform simple tasks such as regularly lubricating moving parts and ensuring the workspace remains free from debris to significantly impact the machine’s efficiency and service life.

Inspiring Project Ideas and Tutorials

For those eager to explore the capabilities of the LaserPecker LP5, numerous project ideas can serve as a springboard. Personalizing home décor items, creating intricate jewelry designs, or manufacturing small mechanical components represent just a few of the potential applications. Additionally, the extensive online community offers countless tutorials and design templates, ensuring users—regardless of their experience level—can fully leverage the capabilities of their cnc glass cutting machine.

Conclusion

The LaserPecker LP5 stands as not just an advanced tool, but an invitation to explore a new horizon of creativity and precision. With its robust set of features, the LP5 is poised to meet the diverse needs of artists, manufacturers, and hobbyists alike. By adhering to best practices and exploring innovative applications, users can unlock the full potential of their investment and push the boundaries of what is achievable with laser engraving technology. Investing in a cnc glass cutting machine today opens a myriad of possibilities for tomorrow.