Title: Enhancing Efficiency with Hydraulic Paper Cutting Machines

Introduction

In recent years, the demand for precise and efficient cutting technology has surged, boosting the popularity of hydraulic paper cutting machines. These machines contribute to streamlined operations across various industries, including print, packaging, and textiles. Understanding the capabilities, specifications, and applications of hydraulic paper cutting machines is essential for those considering investing in this technology. This article offers a comprehensive exploration of hydraulic paper cutting machines, delving into the technology, specifications, material compatibility, safety measures, best practices, and more.

Hydraulic Paper Cutting Technology and Applications

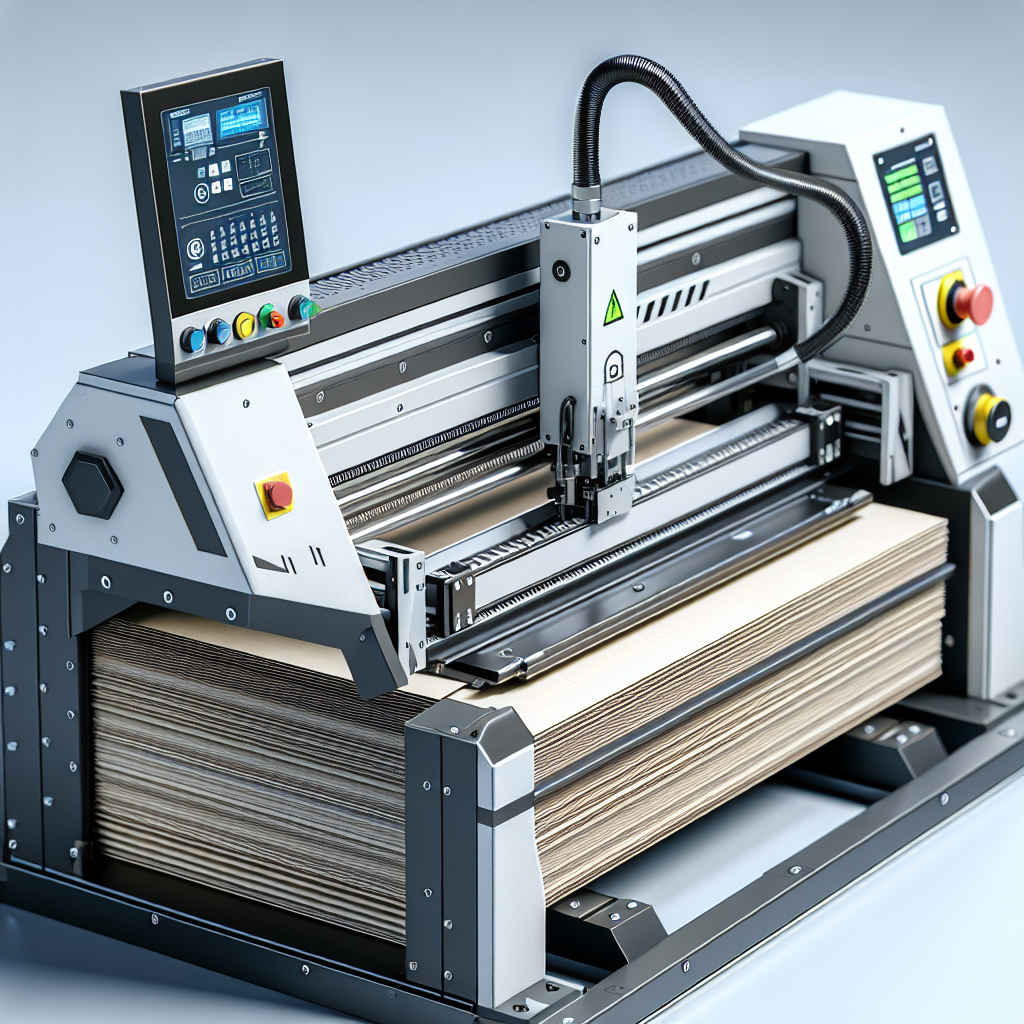

Hydraulic paper cutting machines utilize hydraulic systems to deliver powerful and precise cuts. These machines are essential in numerous applications, including the printing industry for trimming paper, cardboard, and other materials. Hydraulic paper cutting machines excel at handling large volumes, making them ideal for production environments where efficiency and accuracy are paramount.

An important advantage of hydraulic machines is their ability to exert significant pressure, allowing for effortless cutting of thicker materials. As technological advancements continue, new applications in fields such as packaging and textiles demonstrate the versatility and effectiveness of hydraulic paper cutting machines.

Machine Specifications and Features

Understanding the specifications and features of hydraulic paper cutting machines is crucial for selecting a model that aligns with your needs. Machines like the XYZ Hydraulic Cutter, notable for its advanced hydraulic system, offer flexibility and reliable performance. Key parameters to consider include cutting capacity, blade type, and operational speed.

Cutting capacity refers to the maximum thickness of materials the machine can cut, while blade type affects the quality and precision of the cut. Advanced features, such as programmable controls and safety interlocks, enhance usability and performance.

Material Compatibility

A significant advantage of hydraulic paper cutting machines is their compatibility with a wide array of materials, including paper, cardboard, plastics, and textiles. This versatility allows for seamless operations across various applications. Properly adjusting machine settings to match material specifications ensures optimal results when using hydraulic paper cutting machines.

Understanding different material properties helps in selecting the right cutting parameters—such as speed and pressure—to guarantee quality and efficiency. For example, when cutting thick cardboard, different settings must be applied compared to thinner materials, ensuring precision and reducing waste.

Safety Considerations

Operating hydraulic paper cutting machines necessitates strict adherence to safety protocols to prevent accidents. Operators should wear appropriate protective gear, including gloves and safety goggles, to avoid injuries. Additionally, understanding the machine’s safety features, such as emergency stops and blade guards, is critical for safe operation.

Regular maintenance and safety checks are essential to ensure the machine operates correctly and safely. Understanding the risks associated with hydraulic systems, such as hydraulic fluid leaks, is also crucial for maintaining a safe working environment.

Industry Best Practices

Following industry best practices helps maximize the potential of hydraulic paper cutting machines. Ensuring proper machine calibration before each project maintains precision and accuracy. Regularly inspecting and servicing the cutting blades will prolong their lifespan and enhance cutting quality.

Keeping up with the latest industry guidelines and engaging in ongoing training ensures that operators are informed about best practices and innovations, leading to improved efficiency and output quality. Collaborating with fellow operators can also provide valuable insights and support.

Cost-Benefit Analysis

Investing in hydraulic paper cutting machines is a significant financial commitment, necessitating a comprehensive cost-benefit analysis. While initial costs can be considerable, the long-term savings achieved through reduced labor, increased speed, and improved quality often justify the investment.

For businesses, the ability to offer customized and high-quality products can lead to increased customer satisfaction and profitability. Analyzing the machine’s upfront cost against its long-term economic benefits and productivity gains is essential for informed decision-making.

Maintenance Tips

Routine maintenance is vital for prolonging the lifespan of hydraulic paper cutting machines and ensuring consistent performance. Regular inspection of hydraulic systems to check for leaks and pressure issues is necessary. Lubricating moving parts reduces wear and tear, while proper cleaning of blades and components enhances cutting performance.

Storing and handling the machine correctly can prevent damage from environmental factors such as dust and humidity. Following the manufacturer’s preventive maintenance schedule assists in identifying potential issues early, preventing costly repairs.

Project Ideas and Tutorials

New users or those looking to expand their capabilities should explore project ideas and tutorials related to hydraulic paper cutting machines. Projects such as custom packaging, business cards, intricate paper art, and personalized stationery are great starting points.

Tutorials that provide step-by-step instructions for specific cuts or applications can enhance skills and inspire innovative uses for hydraulic paper cutting machines. Utilizing online resources and workshops can boost your understanding and proficiency in operating these machines effectively.

Conclusion

The advent of hydraulic paper cutting machines has transformed cutting operations across multiple industries. Understanding the nuances of this technology—from machine specifications to material compatibility and safety considerations—enables users to maximize the potential of their machines. With hydraulic paper cutting machines providing efficiency and precision, opportunities for creativity and productivity in production processes are vast. Whether you’re considering investing in a hydraulic paper cutting machine or seeking to optimize its use, exploring these diverse aspects can lead to successful and profitable cutting endeavors.

By investing in a hydraulic paper cutting machine, you position your business to capitalize on its many advantages, ensuring smoother operations and superior output across all your cutting needs.