Title: Exploring Laser Engraving Machines in Australia

Introduction

In recent years, the swift evolution of technology has given rise to remarkable innovations in various sectors. One notable advancement, benefiting both large-scale industries and hobbyists alike, is the laser engraving machine australia. Whether you’re a manufacturer aiming to streamline production or a creative enthusiast bringing artistic visions to life, laser engraving machines provide a wealth of applications and advantages. This in-depth article delves into the realm of laser engraving machines, discussing their underlying technology, practical uses, specifications, and other crucial factors.

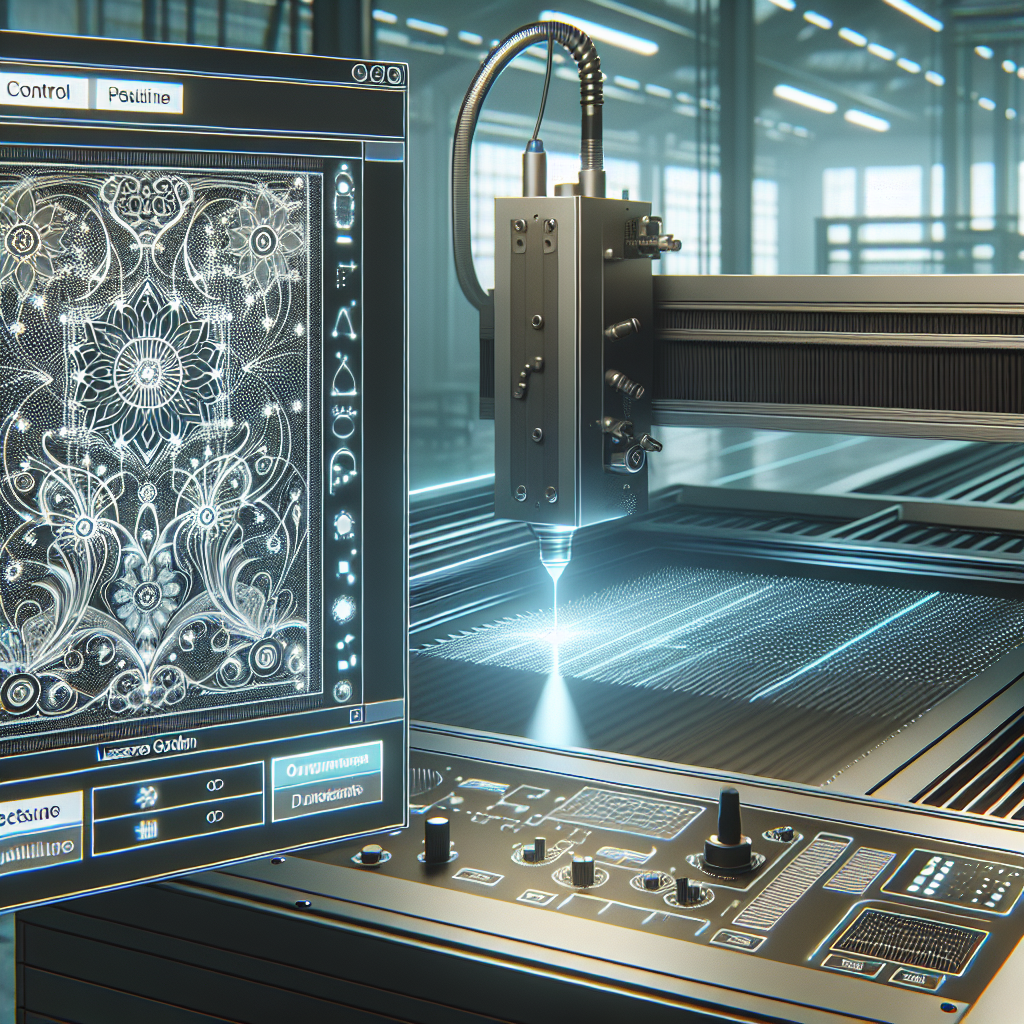

What is Laser Engraving Technology?

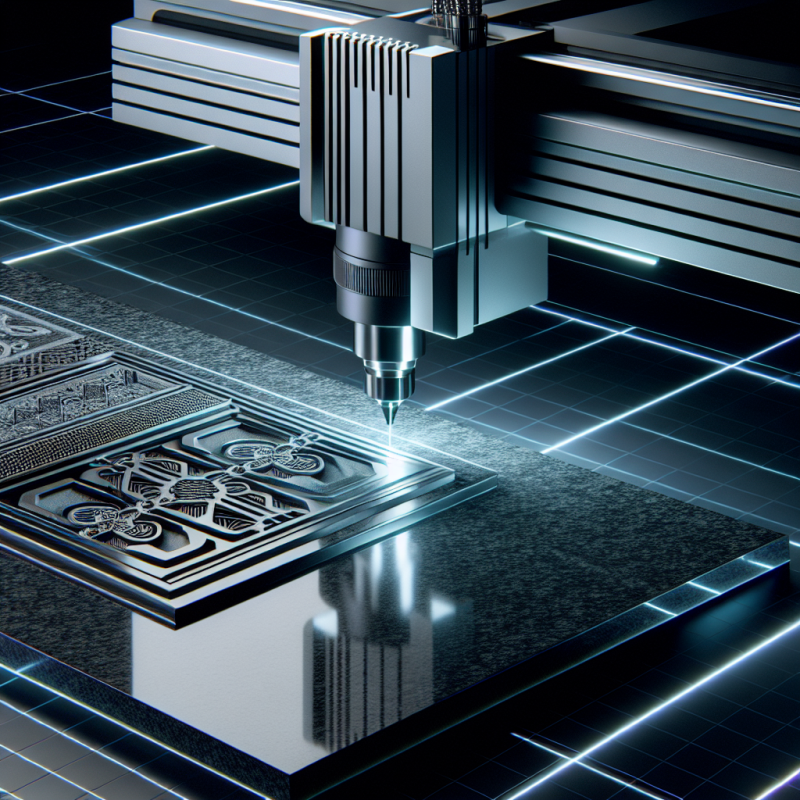

Laser engraving involves using concentrated laser beams to carve designs, text, images, or patterns into various materials with exceptional precision. This process creates a permanent mark by removing the surface layer of the material being worked on. Laser engraving machines are highly favored due to their precision, efficiency, and versatility.

Applications of Laser Engraving Machines

Laser engraving machines are utilized in a multitude of industries for crafting intricate designs and markings. Key applications include:

- Industrial Manufacturing: Engraving serial numbers, barcodes, and company logos on products.

- Jewelry Design: Carving intricate and delicate designs onto precious metals.

- Personalized Gifts and Accessories: Crafting unique messages or images for custom items.

- Prototyping and Model Making: Building precise models and prototypes for testing and presentations.

- Architectural Models: Assisting architects in creating detailed models with engraved elements.

Machine Specifications and Features

When selecting a laser engraving machine australia, it’s important to consider specifications that align with your requirements. Key features to evaluate include:

- Laser Power: Determines material suitability and operational speed.

- Work Area: The size of the engraving area, influencing the dimensions of objects you can work on.

- Resolution: Influences the detail and clarity of the engravings.

- Cooling System: Essential for maintaining optimal temperature and avoiding damage.

- Control Software: User-friendly software is crucial for efficient design and execution.

Material Compatibility

Laser engraving machines can operate on diverse materials, including:

- Metal: Suitable for engraving materials like aluminum, brass, and steel for industrial or decorative purposes.

- Wood: Creating detailed designs on plaques, furniture, and other wooden products.

- Acrylic and Plastics: Ideal for creating signage, keychains, and various plastic items.

- Leather: Producing exquisite designs on leather goods.

- Glass: Etching patterns and personalizations onto glassware.

Safety Considerations

The safe operation of a laser engraving machine australia is crucial to preventing injuries and accidents. Key safety tips include:

- Wearing protective eyewear to guard against laser exposure.

- Ensuring a well-ventilated area to prevent inhaling harmful fumes.

- Regularly maintaining and inspecting the machine to ensure optimal condition.

- Following the manufacturer’s instructions and safety guidelines.

- Keeping the work area free from flammable materials.

Industry Best Practices

To maximize the efficiency and lifespan of your laser engraving machine australia, adhere to industry best practices such as:

- Keeping the lens clean to ensure precision.

- Regularly updating software for new features and improvements.

- Providing adequate training for staff to ensure safe and efficient operation.

- Documenting optimal settings for various materials to ensure consistency.

Cost-Benefit Analysis

While the initial investment in a laser engraving machine australia may be significant, the advantages typically outweigh the costs. Major benefits include:

- High Precision and Quality: Guarantees accuracy and clean engravings.

- Time Efficiency: Reduces the time spent on manual engraving tasks.

- Versatility: Adaptable to a variety of materials and applications.

- Increased Productivity: Enhances production scale without compromising quality.

Maintenance Tips

Consistent maintenance of your laser engraving machine australia is vital for its durability and functionality. Maintenance tips include:

- Regularly cleaning lenses and mirrors to prevent residue buildup.

- Checking and replacing worn parts like belts and motors.

- Keeping software updated for optimal performance.

- Lubricating moving parts to ensure smooth operation.

Project Ideas and Tutorials

Unleash the potential of your laser engraving machine australia with these project ideas:

- Create Custom Wooden Keychains: Craft unique keychains with personalized names or logos.

- Customize Glassware: Etch family names or special dates onto glass cups or bottles.

- Engrave Metal Business Cards: Impress with elegantly engraved metal cards.

- Design Leather Wallets: Create personalized wallet designs as unique gifts.

- Sculpt Delicate Jewelry: Produce intricate patterns on metal jewelry.

With their extensive capabilities, laser engraving machines represent a valuable investment for enhancing creative or industrial projects through precision and efficient engraving technology. By understanding their technology, applications, and maintenance requirements, users can maximize their investment and achieve impressive results.