Exploring Metal Laser Engraving: Precision, Artistry, and Applications

Metal laser engraving has revolutionized the way we create intricate designs, patterns, and text on metallic surfaces. This advanced technique combines precision engineering with artistic creativity to produce highly detailed and durable markings. Whether you’re working in the fields of jewelry design, industrial manufacturing, or custom craftsmanship, metal laser engraving offers unparalleled versatility and quality. In this article, we’ll explore the ins and outs of this innovative process, its benefits, applications, and what makes it a game-changer for modern creators.

What is Metal Laser Engraving?

Metal laser engraving is a cutting-edge technology that uses high-powered lasers to etch or cut intricate designs into metal surfaces. Unlike traditional engraving methods, which often involve mechanical tools and can leave behind rough edges or imperfections, laser engraving ensures clean, precise, and permanent markings. The process involves directing a focused laser beam onto the metal surface, where the intense heat vaporizes or melts the material to create the desired design.

The key advantage of this method lies in its ability to achieve extremely fine details, making it ideal for creating complex patterns, logos, or text that would be challenging to produce with conventional tools. Additionally, laser engraving can be applied to a wide range of metals, including stainless steel, aluminum, titanium, and precious metals like gold and silver.

Benefits of Metal Laser Engraving

Metal laser engraving offers numerous advantages over traditional engraving methods. Let’s take a closer look at some of the key benefits:

- Precision and Accuracy: The laser beam’s pinpoint focus allows for highly detailed and accurate designs, even on a microscopic scale.

- Durability: Engraved markings are permanent and resistant to wear, making them ideal for products that require long-lasting identification or decoration.

- Versatility: The process can be used on various metals and surfaces, accommodating a wide range of creative and industrial applications.

- Speed and Efficiency: Laser engraving machines operate at high speeds, reducing production time while maintaining consistent quality.

- Eco-Friendly: Unlike chemical etching methods, laser engraving produces minimal waste and is free from harmful byproducts.

These benefits make metal laser engraving a preferred choice for industries ranging from jewelry making to automotive manufacturing, where precision and quality are paramount. Whether you’re creating custom wedding bands or intricate mechanical parts, this technology delivers exceptional results every time.

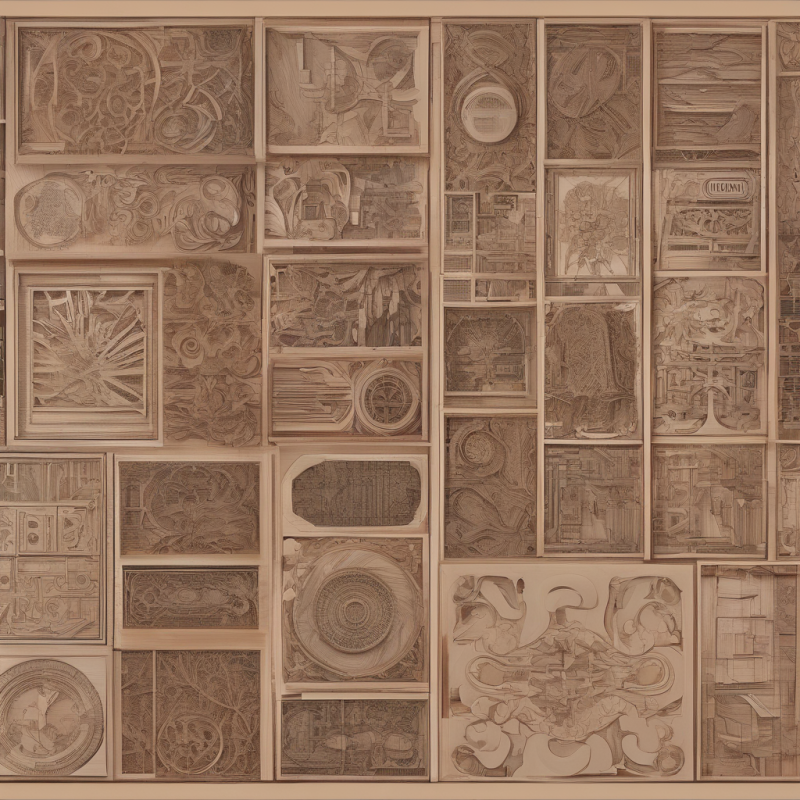

Applications of Metal Laser Engraving

The versatility of metal laser engraving makes it suitable for a wide array of applications. Here are some of the most common uses:

- Jewelry Design: Custom engravings on rings, necklaces, bracelets, and other precious metal items.

- Industrial Marking: Permanent identification codes, serial numbers, and logos on machinery and components.

- Craftsmanship: Decorative engravings on items like cutlery, watches, and decorative art pieces.

- Aerospace and Automotive: High-precision engravings for complex parts requiring detailed markings.

The possibilities are endless, and as technology continues to evolve, so do the applications of this innovative process. Metal laser engraving is no longer just a tool for functional marking; it’s also a medium for artistic expression.

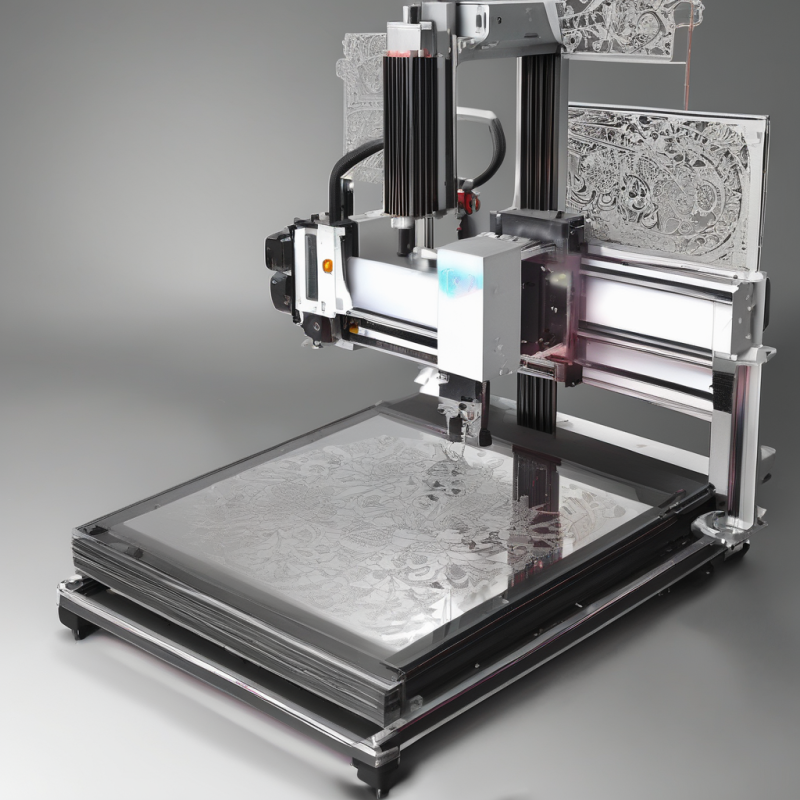

How Does Metal Laser Engraving Work?

To understand how metal laser engraving works, let’s break down the process step by step:

- Design Creation: The first step involves creating a digital design using specialized software. This design is then converted into a file format compatible with the laser engraving machine.

- Material Preparation: The metal surface to be engraved is cleaned and secured in place. Proper preparation ensures optimal results and prevents damage during the engraving process.

- Laser Engraving: The laser beam, guided by the digital design, begins etching or cutting into the metal surface. The intensity and speed of the laser can be adjusted to achieve different effects, from shallow engravings to deep cuts.

- Post-Processing: After engraving, the piece may undergo additional treatments such as polishing or coating to enhance its appearance and durability.

The entire process is highly automated, allowing for consistent quality and reduced human error. This makes it an ideal choice for both small-scale craftsmanship and large-scale industrial production.

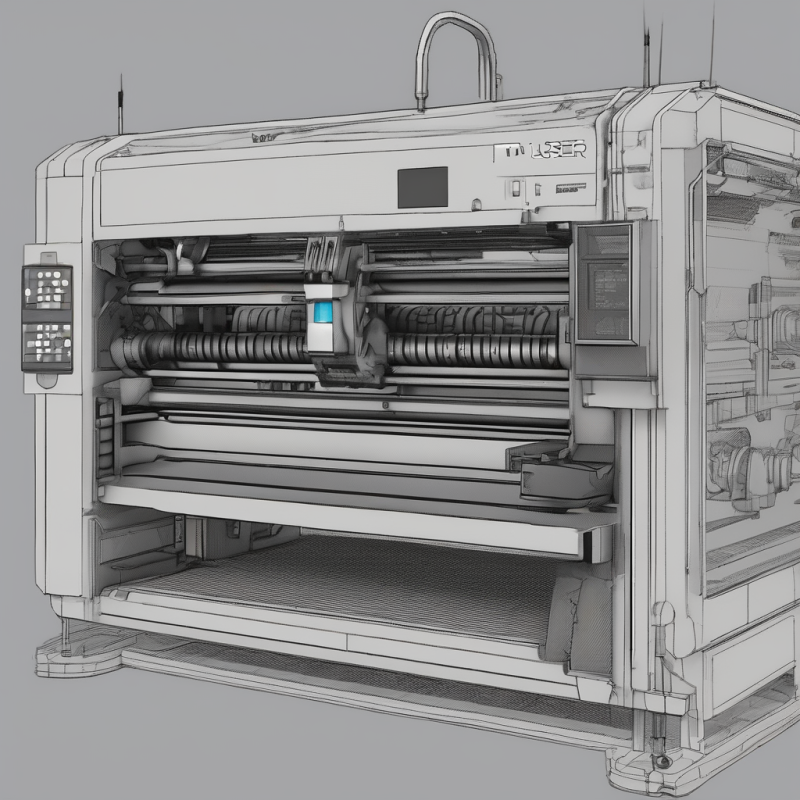

Choosing the Right Laser Engraving Machine

When selecting a laser engraving machine for metal work, several factors should be considered:

- Type of Metal: Different metals have varying melting points and thermal properties, so it’s essential to choose a machine capable of handling the specific materials you’ll be working with.

- Engraving Depth: Determine whether your project requires shallow or deep engravings and select a machine accordingly.

- Budget: Laser engraving machines come in a wide range of prices, from affordable desktop models to high-end industrial systems. Choose one that aligns with your needs and budget.

For those looking for a reliable and versatile option, the [insert product name] laser engraving machine stands out as an excellent choice. Designed for precision and ease of use, it’s perfect for both hobbyists and professional creators.

Tips for Successful Metal Laser Engraving

To achieve the best results with your metal laser engraving projects, consider the following tips:

- Start Small: If you’re new to laser engraving, begin with simple designs and gradually work your way up to more complex patterns.

- Experiment with Settings: Play around with different laser settings, such as power level and speed, to find the optimal combination for your material.

- Use Protective Gear: Always wear safety goggles and gloves when operating a laser engraving machine to protect yourself from potential hazards.

By following these guidelines and practicing proper techniques, you can unlock the full potential of metal laser engraving and create stunning works of art or functional pieces that will stand the test of time.

Frequently Asked Questions

If you’re new to metal laser engraving, here are some common questions and answers to help you get started:

- Is laser engraving safe for all types of metals?

- Can I repair mistakes made during laser engraving?

- How long does it take to learn laser engraving?

Laser engraving is suitable for most metals, but certain materials may require special settings or precautions. Always consult your machine’s user manual or a professional for guidance.

Engraved markings are permanent, so it’s crucial to ensure accuracy from the start. However, in some cases, minor mistakes can be polished out or covered with additional engravings.

The learning curve varies depending on your experience and dedication. With practice and the right resources, you can master the basics in a matter of weeks.

If you have more questions or need further assistance, feel free to reach out to our team of experts who are happy to help you navigate the world of metal laser engraving.

The Future of Metal Laser Engraving

As technology continues to advance, we can expect even more innovations in the field of metal laser engraving. From faster machines to improved software capabilities, the future looks bright for creators who rely on this cutting-edge tool. Additionally, as sustainability becomes a greater priority, we may see further developments in eco-friendly laser engraving methods that minimize waste and energy consumption.

Whether you’re a seasoned artisan or just starting out, embracing metal laser engraving can open up new creative possibilities and elevate your work to the next level. With its precision, versatility, and efficiency, this technology is sure to remain at the forefront of modern craftsmanship for years to come.

Final Thoughts

Metal laser engraving is more than just a tool; it’s a gateway to limitless creativity and innovation. Whether you’re crafting bespoke jewelry or producing high-tech components, this process offers unmatched precision and versatility that can take your projects to new heights. If you haven’t explored the world of metal laser engraving yet, now is the perfect time to dive in and discover its incredible potential!

Ready to get started? Check out our top picks for or visit our to learn more about this fascinating craft. Happy creating!