Exploring Metal Laser Engraving: Precision, Durability, and Customization

Metal laser engraving has revolutionized industries ranging from jewelry making to industrial manufacturing. This cutting-edge technology offers unparalleled precision, durability, and customization options, making it a favorite among professionals and hobbyists alike. Whether you’re creating intricate designs on metal surfaces or marking components for identification, metal laser engraving provides a versatile solution that delivers exceptional results. In this article, we’ll explore the intricacies of metal laser engraving, its applications, benefits, and considerations to help you determine if it’s the right choice for your needs.

What is Metal Laser Engraving?

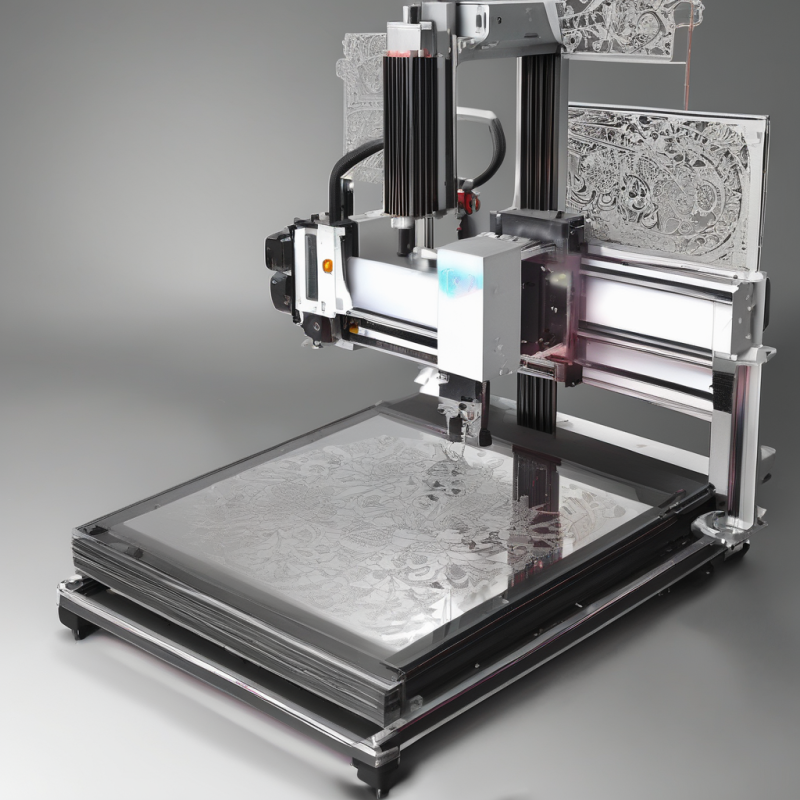

Metal laser engraving is a process that uses a focused laser beam to etch or cut designs, patterns, or text onto metal surfaces. Unlike traditional methods like acid etching or mechanical engraving, laser engraving offers unparalleled precision and versatility. The laser beam creates intricate details with minimal material removal, leaving behind sharp, crisp lines that are resistant to wear and tear.

The process involves directing a high-powered laser at the metal surface, which vaporizes or melts the material to create the desired design. This method is not only fast and efficient but also highly accurate, capable of producing intricate patterns and text in sizes as small as 0.1mm. Whether you’re working with stainless steel, aluminum, brass, or other metals, laser engraving ensures a polished finish that enhances the aesthetic appeal of your projects.

Benefits of Metal Laser Engraving

Metal laser engraving offers numerous advantages over traditional engraving methods. Here are some of the key benefits:

- Precision and Detail: The laser beam can create highly detailed designs with pinpoint accuracy, making it ideal for complex patterns or fine text.

- Durability: Laser-engraved marks are permanent and resistant to fading, ensuring long-lasting results even in harsh environments.

- Versatility: Suitable for a wide range of metals, laser engraving can be used on stainless steel, aluminum, brass, copper, and more.

- Speed: The process is much faster than traditional methods, allowing for quick turnaround times on large-scale projects.

- Clean Finish: Unlike mechanical engraving, laser engraving leaves behind a smooth, polished surface with no burrs or rough edges.

These benefits make metal laser engraving an excellent choice for industries such as jewelry making, automotive manufacturing, electronics, and even personalized gifts. If you’re looking for a reliable and efficient way to customize metal products, this technology is worth considering.

Applications of Metal Laser Engraving

Metal laser engraving has a wide range of applications across various industries. Here are some common uses:

- Jewelry Making: Creating intricate designs, patterns, and engravings on rings, necklaces, bracelets, and other precious metal items.

- Industrial Marking: Engraving serial numbers, barcodes, logos, or other identifying marks on metal components for traceability.

- Custom Gifts: Personalizing items like name tags, plaques, trophies, and keychains with custom designs or text.

- Automotive Industry: Etching logos, part numbers, or decorative patterns on car parts, accessories, and trimmings.

- Electronics: Marking circuit boards, connectors, and other components with detailed engravings for identification or branding.

These applications highlight the versatility of metal laser engraving. Whether you’re working on small-scale projects or large industrial operations, this technology can adapt to your needs with ease.

Factors to Consider When Choosing Metal Laser Engraving

If you’re considering metal laser engraving for your next project, there are several factors to keep in mind:

- Type of Metal: Different metals have varying properties that affect the engraving process. For example, stainless steel is highly reflective and requires a specific wavelength of laser light for optimal results.

- Design Complexity: The intricacy of your design will influence the type of laser machine and settings required. More detailed designs may need higher-powered lasers or specialized software.

- Surface Finish: Laser engraving can leave behind a polished finish, but it’s essential to consider the desired aesthetic outcome. Some applications may require additional post-processing steps for certain finishes.

- Budget and Equipment: Investing in a metal laser engraving machine requires an initial capital outlay. Consider your budget and the scale of your projects when selecting equipment.

By carefully evaluating these factors, you can ensure that metal laser engraving meets your project requirements and delivers the desired results.

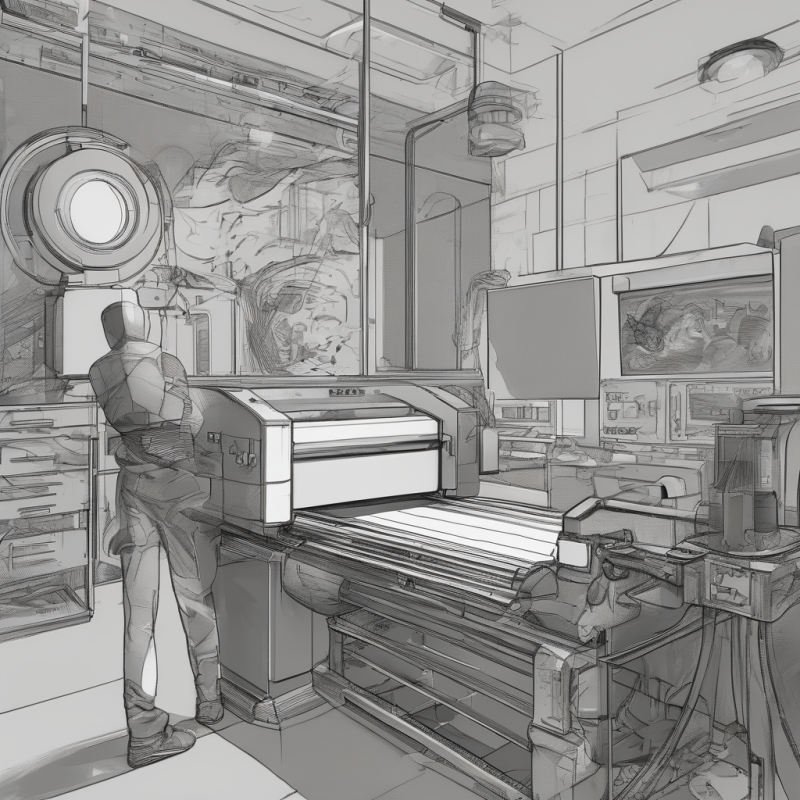

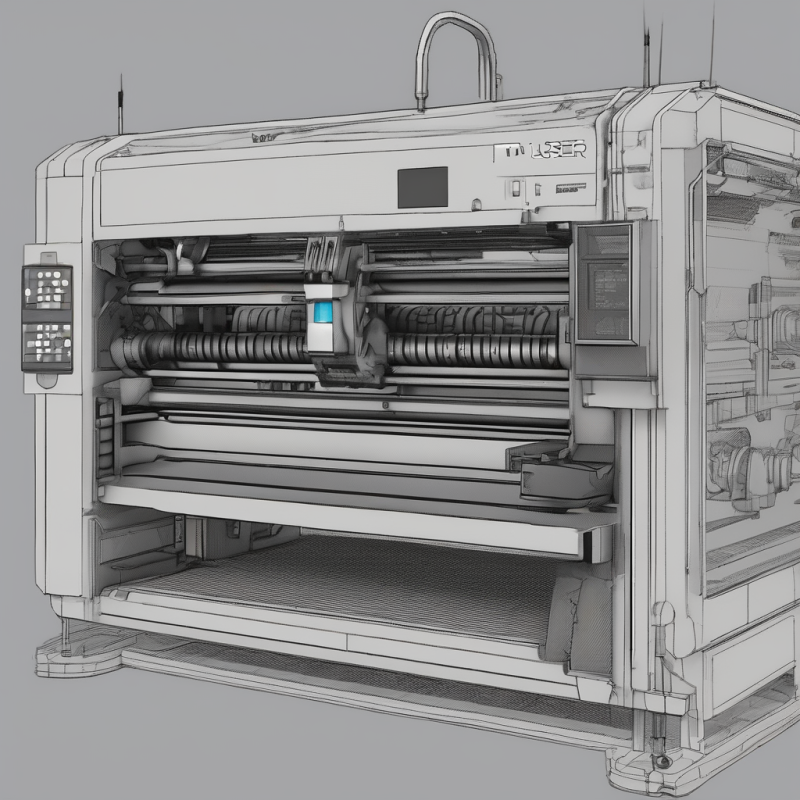

Choosing the Right Equipment for Metal Laser Engraving

To get started with metal laser engraving, you’ll need the right equipment. Here are some key components to consider:

- Laser Machine: The heart of any laser engraving setup is the machine itself. Look for a machine that offers adjustable power levels, variable focal lengths, and compatible with different materials.

- Lens and Focusing Optics: High-quality lenses ensure precise beam focus, which is critical for achieving sharp engravings on metal surfaces.

- Software: Laser engraving software plays a crucial role in designing and controlling the engraving process. Choose software that supports vector graphics and offers advanced features like nesting and automated path optimization.

- Air Assist System: For metal engraving, an air assist system helps cool the laser beam and remove debris, ensuring cleaner cuts and engravings.

If you’re looking for a reliable and affordable option, consider checking out our selection of metal laser engraving machines designed to meet your specific needs. With the right equipment, you can unlock the full potential of this innovative technology and create stunning metal products with ease.

Frequently Asked Questions About Metal Laser Engraving

If you’re new to metal laser engraving, you might have some questions. Here are answers to some of the most common ones:

- Q: Can I use laser engraving on all types of metals?

A: Yes, laser engraving works on a wide range of metals, including stainless steel, aluminum, brass, copper, and titanium. However, some metals may require specific settings or preprocessing to achieve optimal results.

- Q: Is laser engraving better than traditional methods?

A: Laser engraving offers several advantages over traditional methods, such as higher precision, faster processing times, and the ability to create intricate designs. However, it may not be suitable for all applications, so it’s essential to evaluate your specific needs.

- Q: How durable are laser-engraved marks?

A: Laser-engraved marks are highly durable and resistant to wear, making them ideal for long-lasting identification or decorative purposes.

If you have more questions about metal laser engraving or need guidance on selecting the right equipment, feel free to reach out to our team of experts. We’re here to help you achieve your creative vision with precision and efficiency.

Conclusion

Metal laser engraving is a game-changer for anyone looking to create custom designs or markings on metal surfaces. With its precision, durability, and versatility, this technology has become an indispensable tool in industries ranging from jewelry making to industrial manufacturing. Whether you’re working on small-scale projects or large-scale production, investing in a high-quality laser engraving machine can elevate your work to new heights.

If you’re ready to take the plunge into the world of metal laser engraving, explore our selection of top-of-the-line equipment and discover how this technology can transform your projects. Don’t hesitate to reach out if you have any questions or need assistance in choosing the right tools for your needs. Happy engraving!