Exploring the Advanced Features and Applications of the Laser Cutter Engraver

Laser technology has revolutionized various industries, offering precision and efficiency that traditional methods often struggle to match. Among the many innovations in this field is the laser cutter engraver, a versatile tool designed for intricate cutting and engraving tasks. Whether you’re working in woodworking, metal fabrication, or custom design, this machine has become an indispensable asset. In this article, we’ll delve into the features, applications, benefits, and maintenance of the laser cutter engraver, answering your questions along the way.

Understanding the Laser Cutter Engraver

The laser cutter engraver is a cutting-edge tool that combines precision and power, enabling users to perform both cutting and engraving with remarkable accuracy. This machine utilizes a fiber laser, which is known for its high efficiency, long service life, and ability to work on a wide range of materials. The laser cutter engraver is designed for professionals who require detailed and consistent results in their projects.

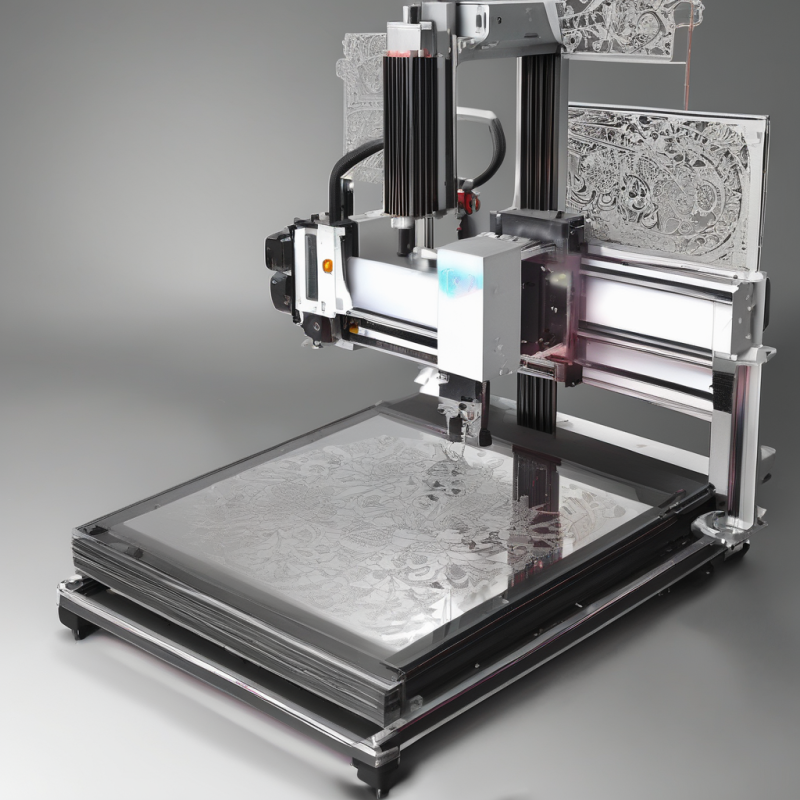

One of the standout features of this machine is its ability to handle various materials, including wood, metal, plastic, and glass. This versatility makes it a valuable addition to workshops, factories, and custom design studios. Whether you’re creating intricate designs for jewelry, personalizing gifts, or producing industrial parts, the laser cutter engraver can meet your needs.

Key Features of the Laser Cutter Engraver

The boasts a range of features that set it apart from traditional cutting and engraving tools. Here are some of its key advantages:

- High Precision: The machine operates with pinpoint accuracy, ensuring clean cuts and sharp engravings every time.

- Versatile Material Compatibility: It works seamlessly on various materials, offering flexibility for different projects.

- User-Friendly Interface: Equipped with an intuitive control panel, the machine is easy to operate, even for those new to laser cutting and engraving.

- Durable Construction: Built with high-quality components, this machine is designed for long-lasting performance and minimal maintenance.

- Energy Efficiency: The fiber laser technology ensures lower energy consumption compared to traditional methods.

These features make the laser cutter engraver a cost-effective and efficient solution for businesses looking to enhance their production capabilities.

Applications of the Laser Cutter Engraver

The applications of the are vast and varied. From small-scale custom projects to large industrial operations, this machine has proven its versatility across multiple industries.

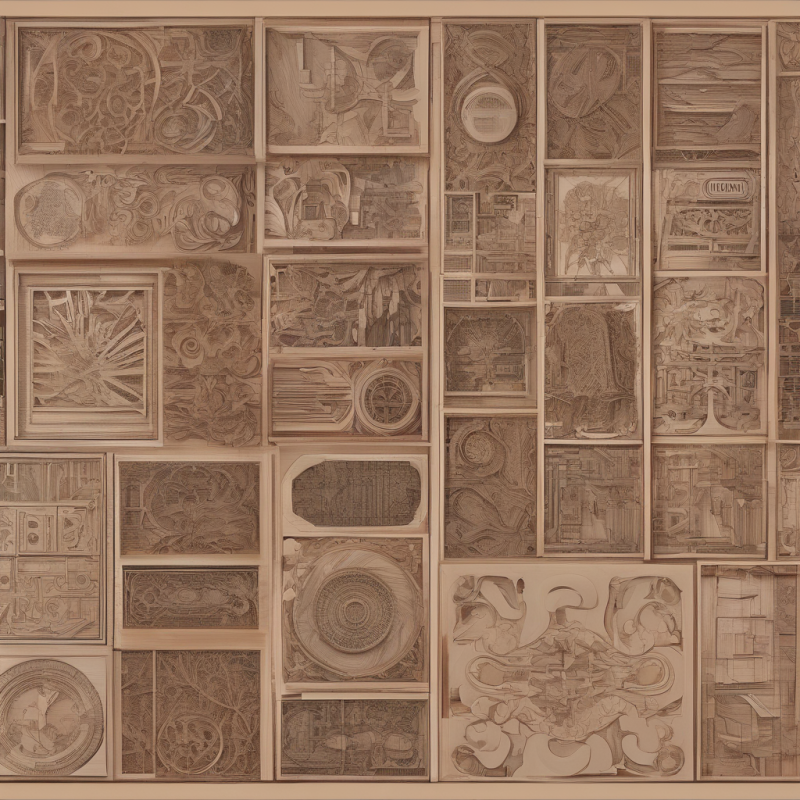

In the woodworking industry, it’s used for creating decorative designs, furniture parts, and signage. Metal fabrication shops rely on it for cutting intricate patterns and engravings on metal surfaces. The laser cutter engraver is also a favorite among jewelry makers, as it allows for precise detailing on precious metals and stones.

Beyond these industries, the machine finds applications in advertising, where it’s used to create custom signs and promotional items. It’s also popular in the art world, enabling artists to bring their designs to life with precision and detail.

Benefits Over Traditional Methods

Compared to traditional cutting and engraving methods, the laser cutter engraver offers several advantages:

- Precision: Laser technology ensures that cuts and engravings are precise and consistent, minimizing waste and improving product quality.

- Speed: The machine operates at high speeds, significantly reducing production time compared to manual methods.

- Versatility: Its ability to work on multiple materials makes it a versatile tool for various projects.

- Cost-Effectiveness: Despite the initial investment, the machine’s efficiency and longevity make it a cost-effective solution in the long run.

These benefits make the an excellent choice for businesses looking to upgrade their production processes.

Maintenance and Care of the Laser Cutter Engraver

Like any high-tech equipment, proper maintenance is crucial to ensure the longevity and optimal performance of the laser cutter engraver. Here are some tips for maintaining your machine:

- Cleanliness: Regularly clean the machine’s surfaces and optics to prevent dust buildup, which can affect performance.

- Lubrication: Follow the manufacturer’s instructions for lubricating moving parts to ensure smooth operation.

- Calibration: Periodically calibrate the machine to maintain its accuracy and precision.

- Software Updates: Keep the machine’s software up to date to take advantage of new features and improvements.

By following these maintenance tips, you can extend the life of your and ensure it continues to perform at its best.

Frequently Asked Questions

Q: Can the laser cutter engraver work on all materials?

A: While it’s highly versatile, the machine works best with non-reflective materials. Some materials may require special settings or precautions for optimal results.

Q: Is it easy to learn how to use the laser cutter engraver?

A: Yes, the intuitive interface and user-friendly controls make it accessible even for those without prior experience in laser cutting and engraving.

Q: What is the typical maintenance schedule for this machine?

A: Regular cleaning, lubrication, and calibration are recommended. Refer to the user manual for specific guidelines based on your usage frequency.

Conclusion

The is a powerful tool that has transformed the way businesses approach cutting and engraving tasks. Its precision, versatility, and efficiency make it an invaluable asset for professionals across multiple industries. By understanding its features, applications, and maintenance requirements, you can unlock its full potential and take your projects to new heights.

Whether you’re a seasoned professional or just starting out, the laser cutter engraver offers the tools you need to create intricate designs with ease and accuracy. Invest in this cutting-edge technology today and elevate your production capabilities to the next level!