Title: Exploring the Benefits and Costs of Tube Laser Cutting Machines

Introduction

The evolution of modern manufacturing has brought numerous tools into the spotlight, with the tube laser cutting machine being one of the most prominent. This intricate piece of technology allows for precision and flexibility that was unimaginable just a few decades ago. Understanding the tube laser cutting machine price is crucial for making informed purchasing decisions, whether you’re a seasoned professional or just getting started in the field.

Laser Engraving Technology and Applications

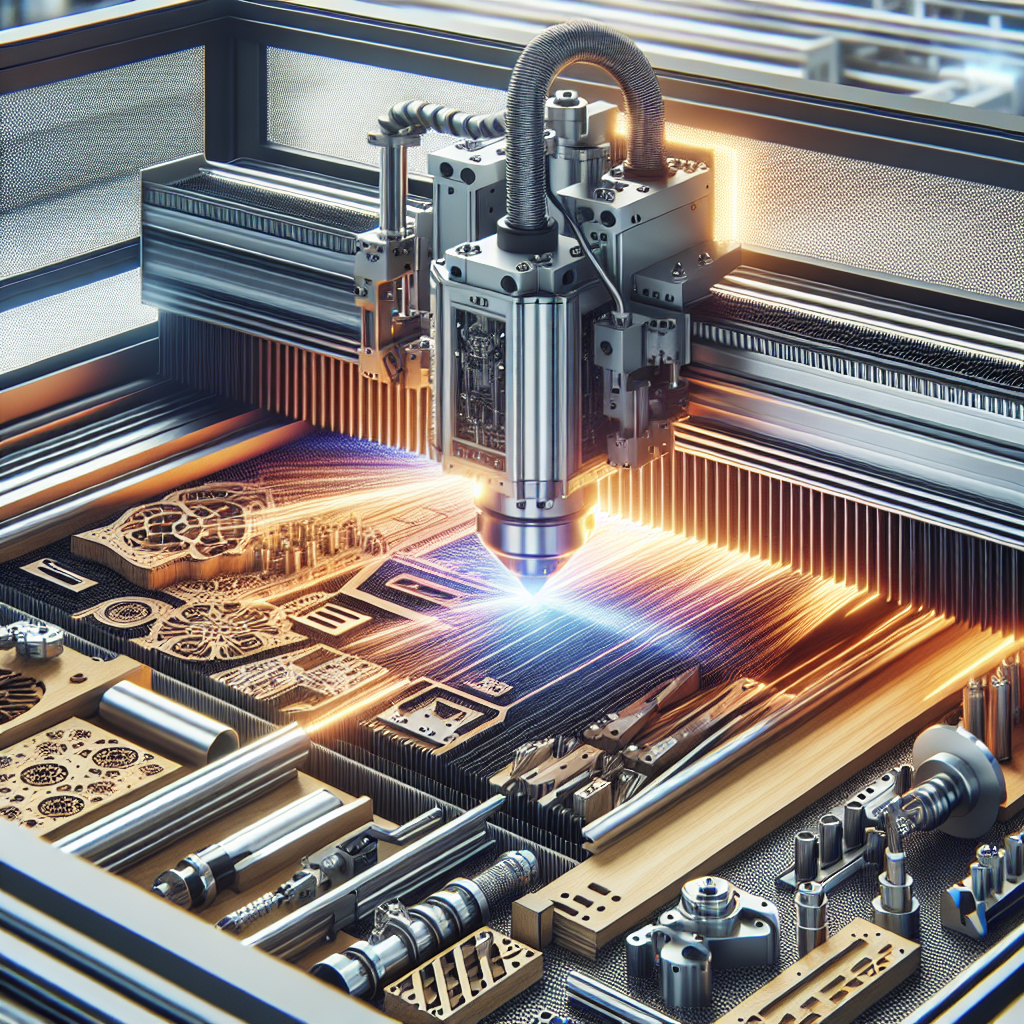

Laser engraving machines have transformed how businesses approach design and production. By utilizing advanced laser technology, these machines can precisely cut and engrave a wide variety of materials, including metals, plastics, and wood. The applications are vast, ranging from intricate jewelry designs to complex industrial parts. The precision offered by laser engravers ensures minimal material wastage, leading to cost savings and increased efficiency.

One of the most exciting applications of laser engraving technology is in custom-made products. Whether it’s crafting personalized gifts or creating one-of-a-kind art pieces, laser engravers offer artists and craftsmen the tools they need to bring their visions to life. Companies in industries such as automotive, aerospace, and consumer electronics have also adopted this technology to streamline production processes. Understanding the tube laser cutting machine price can help businesses assess its role in these applications.

Machine Specifications and Features

When considering investing in a laser engraving machine, it’s essential to understand its specifications and features. The versatility of a tube laser cutting machine largely hinges on its power, speed, and precision. With the ability to perform complex cuts and engravings, these machines feature cutting-edge laser tubes that deliver unmatched accuracy.

The tube laser cutting machine price often reflects its capabilities. Machines with higher power levels can cut through thicker materials quickly and with greater precision, making them ideal for industrial applications. Additionally, ease of use, software compatibility, and maintenance requirements can all influence the overall cost and usability of the machine.

Material Compatibility

A critical aspect of selecting the right laser engraving machine is understanding its material compatibility. Not all machines can handle every type of material, so it’s vital to match the machine’s capabilities with your project needs. Most tube laser machines can cut and engrave metals, including steel and aluminum, as well as non-metals like plastic and wood.

What happens when you try to engrave more complex materials, such as glass or ceramics? While certain laser engravers can handle these materials, it’s essential to confirm the machine’s specifications beforehand. Compatibility not only affects the quality of the finished product but also impacts the machine’s longevity and maintenance needs.

Safety Considerations

Safety is an integral component of operating laser engraving machines. Given the intense light emitted by laser beams, it’s crucial to adhere to safety standards to prevent accidents and injuries. Safety goggles, ventilation systems, and protective enclosures are common safety measures associated with laser machines.

Another question to consider: How safe is it to operate a tube laser machine in a small workshop or home environment? With proper training and safety protocols, these machines can be safely operated in various settings. Familiarizing yourself with emergency shutdown procedures and routine safety checks can further mitigate risks.

Industry Best Practices

To maximize the benefits of your laser engraving machine, it’s beneficial to follow industry best practices. This includes regular maintenance, optimizing laser settings for specific materials, and adhering to safety protocols. Joining industry forums and attending workshops can provide valuable insights into effective techniques and emerging trends.

Experts often emphasize the importance of trial and error when handling new materials or complex projects. By experimenting with different settings and parameters, you can discover the optimal configurations that best suit your machine and enhance its performance.

Cost-Benefit Analysis

Conducting a cost-benefit analysis is crucial when considering the purchase of a tube laser cutting machine. The initial investment can be significant, especially for businesses just starting out. However, by analyzing the tube laser cutting machine price in relation to potential cost savings, increased production speed, and precision, the investment can be justified as a long-term asset.

It’s also essential to consider the potential revenue streams that a laser machine can open up. By broadening your product offerings and appealing to new markets, the revenue potential can offset the initial purchase cost significantly. How can businesses effectively capitalize on these machines to boost profitability? Understanding the tube laser cutting machine price helps inform strategies for achieving this goal.

Maintenance Tips

Proper maintenance is key to extending the lifespan of your laser engraving machine and ensuring optimal performance. Regularly cleaning the laser lens, checking alignment, and updating software are vital maintenance tasks. Preventive maintenance not only avoids unexpected breakdowns but also maintains the machine’s efficiency.

Users often ask: What are the common maintenance challenges faced by laser machine operators? Among them are issues related to laser tube longevity and alignment accuracy. Staying ahead of these challenges with proactive maintenance can vastly improve the machine’s reliability and functionality.

Project Ideas and Tutorials

The versatility of laser engraving machines makes them suitable for a plethora of creative and industrial projects. Popular projects include creating bespoke jewelry, designing customized signage, and developing intricate architectural models. For hobbyists and small business owners looking to explore laser engraving, numerous tutorials are available online to guide you through various creative processes.

Another common question is: What are some beginner-friendly projects to start with? For those new to laser engraving, starting with simple designs and gradually working towards more complex projects can provide a solid foundation of skills and confidence. Leveraging video tutorials and guided projects from the laser machine community can be invaluable in this learning journey.

Evaluating the Tube Laser Cutting Machine Price

As previously mentioned, understanding the tube laser cutting machine price is paramount when considering this purchase. Different models and specifications can result in a wide range of prices, making it essential to evaluate your specific needs against the cost. Investing in a more advanced model may come with a higher price tag but often offers features that can enhance productivity and efficiency in the long run.

Furthermore, buyers should research various manufacturers and suppliers to find the best deal while ensuring quality. Reviews and testimonials from existing users can also provide insight into the expected performance of different machines and their relative prices in the market.

Conclusion

In conclusion, investing in a tube laser cutting machine requires a comprehensive understanding of its features, benefits, and applications. With strategic planning and adherence to best practices, these machines can significantly enhance workflow, creativity, and profitability in various industries. By ensuring that you assess the tube laser cutting machine price in relation to your business goals, you pave the way for innovation and opportunities in your future endeavors.

Ultimately, being well-informed about the tube laser cutting machine price and aligning it with your project’s unique requirements will greatly aid in making the right decision for your manufacturing processes.