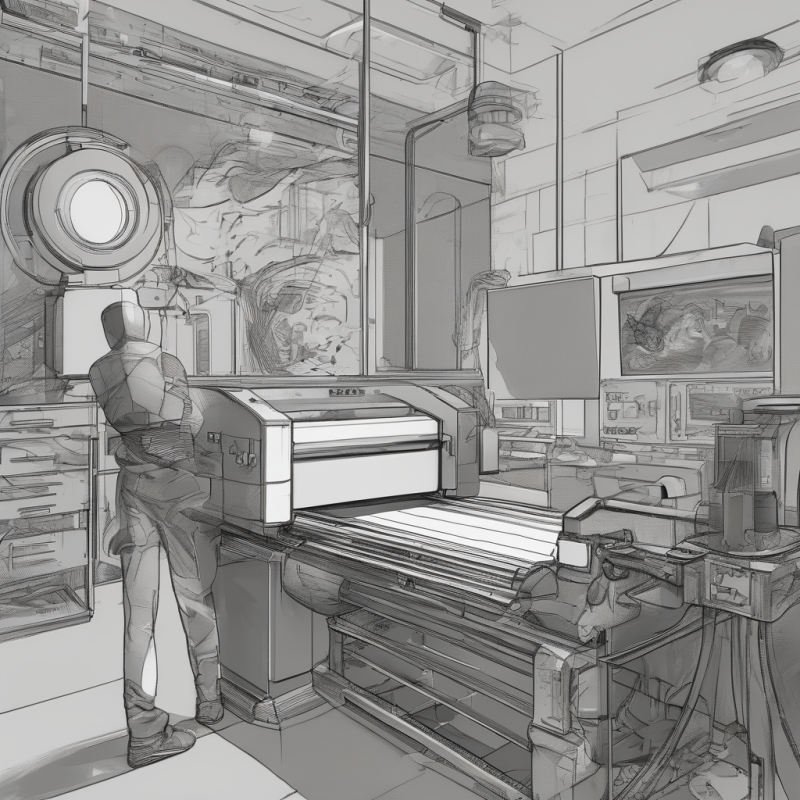

Exploring the Capabilities of a Laser CNC Cutter: A Comprehensive Guide

Laser cutting technology has revolutionized industries ranging from manufacturing to artistry. With precision and versatility, a laser CNC cutter stands out as a game-changer for both small-scale hobbyists and large industrial operations. In this article, we’ll delve into the features, benefits, and applications of this innovative tool, while also addressing common questions and considerations for potential buyers.

What is a Laser CNC Cutter?

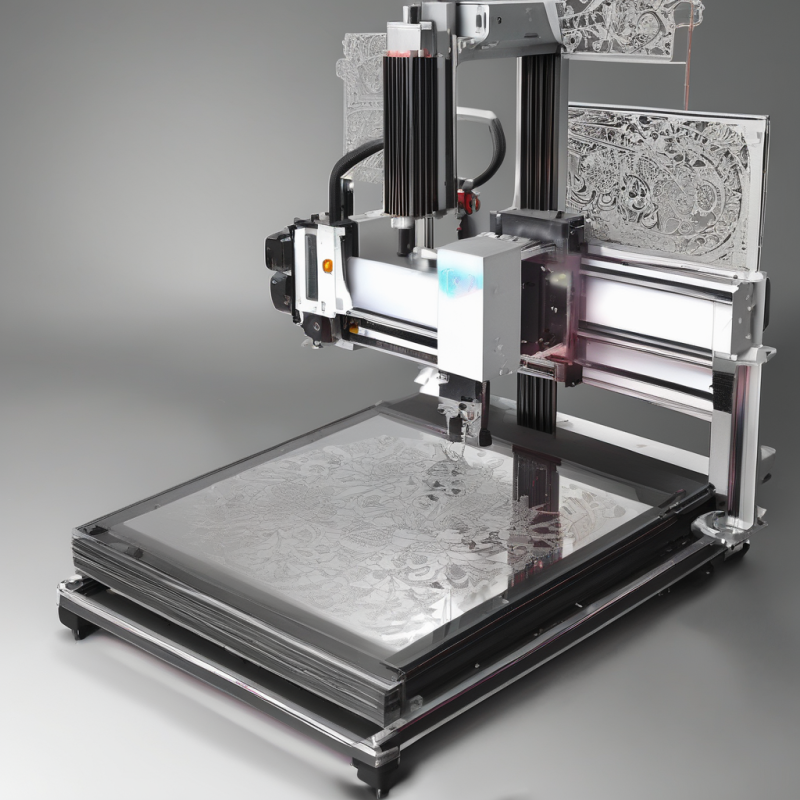

A laser CNC cutter combines the precision of computer numerical control (CNC) with the power of laser technology. Unlike traditional cutting methods, which often rely on mechanical tools, this machine uses a focused beam of light to cut, engrave, or mark materials with exceptional accuracy. The CNC aspect allows for programmable automation, enabling users to create intricate designs and patterns with ease.

One of the standout features of a laser CNC cutter is its ability to work with a wide variety of materials, including metals, plastics, wood, and even glass. This makes it an invaluable tool for industries such as:

- Metal fabrication

- Furniture making

- Jewelry design

- Signage production

- Prototyping and R&D

Whether you’re creating custom parts for machinery or crafting decorative items, a laser CNC cutter offers unparalleled flexibility and precision. But how exactly does it work? Let’s break it down.

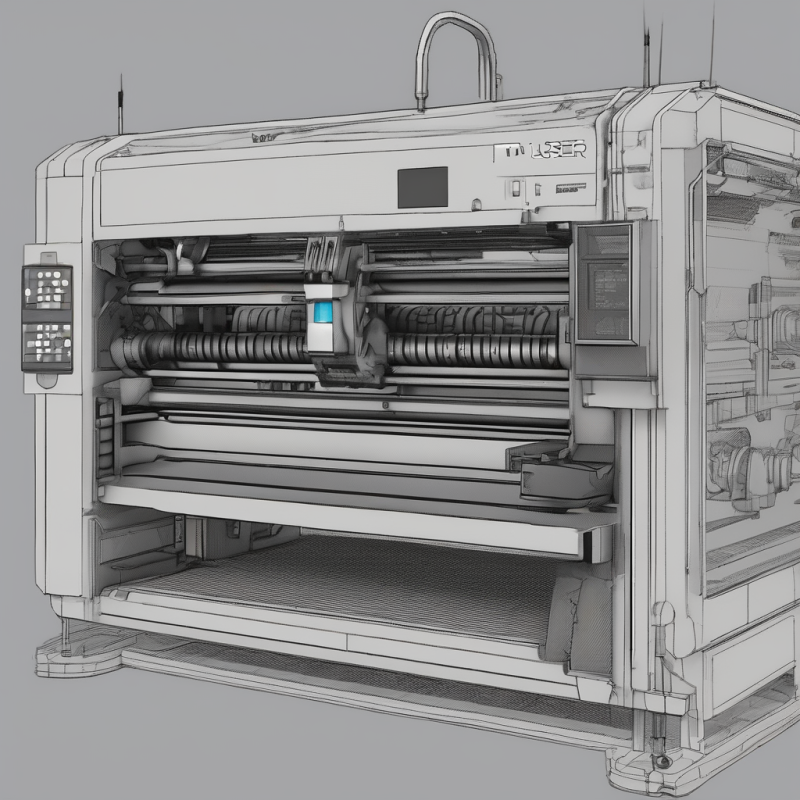

The Science Behind Laser Cutting

Laser cutting involves the use of a high-powered laser beam to melt, burn, or vaporize material along a programmed path. The process begins with designing the desired shape or pattern using CAD (Computer-Aided Design) software. This design is then converted into instructions for the CNC machine, which controls the movement of the laser head.

The laser itself is typically a diode laser, which is known for its efficiency and long service life. The beam is focused through a lens to achieve the necessary intensity for cutting or engraving. Depending on the material being processed, the machine may also use assist gases (such as oxygen or compressed air) to enhance the cutting process.

One key advantage of laser cutting over traditional methods is its ability to produce complex shapes and patterns without the need for physical tooling. This reduces costs and speeds up production, especially for one-off or small-batch projects.

Applications of a Laser CNC Cutter

The versatility of a laser CNC cutter makes it suitable for an array of applications:

- Cutting metal sheets: Precision cutting of steel, aluminum, and other metals for machinery parts or decorative elements.

- Engraving wood and plastics: Creating detailed designs for furniture, signage, or custom gifts.

- Marking and coding: Adding serial numbers, barcodes, or logos to products with permanent precision.

- Prototyping: Rapid production of prototypes for testing and development purposes.

- Jewelry making: Crafting intricate designs in precious metals and gemstones.

These applications highlight the machine’s adaptability, making it a valuable asset for businesses looking to enhance their production capabilities or diversify their services.

Advantages of Using a Laser CNC Cutter

Compared to traditional cutting methods, a laser CNC cutter offers several advantages:

- Precision and accuracy: The laser beam ensures clean, precise cuts with minimal material waste.

- Speed and efficiency: Automated processes allow for faster production times, especially for complex designs.

- Versatility: Capable of working with a wide range of materials and thicknesses.

- Reduced setup time: No need for physical tooling changes between jobs.

- Minimal maintenance: Diode lasers are durable and require less frequent servicing compared to other laser types.

These benefits make the laser CNC cutter a cost-effective solution for businesses looking to streamline their operations and improve product quality.

Frequently Asked Questions About Laser CNC Cutters

If you’re considering investing in a laser CNC cutter, you may have several questions. Let’s address some of the most common ones:

- What materials can I cut with a laser CNC cutter?

A laser CNC cutter can work with various materials, including metals (steel, aluminum), plastics, wood, and even glass. The specific capabilities depend on the machine’s power and configuration.

- How easy is it to learn how to use a laser CNC cutter?

While some training may be required, modern machines are designed with user-friendly interfaces and software. Many operators can become proficient within a few weeks of practice.

- What are the maintenance requirements?

Laser CNC cutters generally require minimal maintenance compared to traditional cutting tools. Regular cleaning of the optics and occasional lubrication of moving parts are typically sufficient to ensure optimal performance.

- Is it safe to use a laser CNC cutter?

Yes, but like any industrial tool, proper safety precautions must be taken. This includes wearing protective eyewear and ensuring adequate ventilation in the workspace.

Choosing the Right Laser CNC Cutter for Your Needs

When selecting a laser CNC cutter, it’s essential to consider factors such as:

- Power output: Higher power lasers are suitable for thicker or harder materials.

- Cutting speed: Determine how quickly you need the machine to process your projects.

- Material compatibility: Ensure the machine can handle the types of materials you’ll be working with.

- Budget: Laser CNC cutters vary widely in price, so it’s important to find a model that offers the best value for your specific needs.

If you’re looking for a reliable and cost-effective solution, consider exploring options like the laser CNC cutter available at [insert link]. This machine is designed to meet the demands of both small-scale and industrial applications while maintaining high precision and durability.

Conclusion

A laser CNC cutter represents a significant advancement in cutting technology, offering unparalleled precision, versatility, and efficiency. Whether you’re working on intricate designs or large-scale production runs, this machine can elevate your projects to new heights. By understanding its features, applications, and benefits, you’ll be better equipped to decide if it’s the right tool for your needs.

If you have any further questions or are ready to invest in a laser CNC cutter, we encourage you to explore our selection at [insert link]. Don’t miss out on this opportunity to transform your manufacturing process!