Exploring the Features of the Industrial Laser Engraver: Precision Meets Innovation

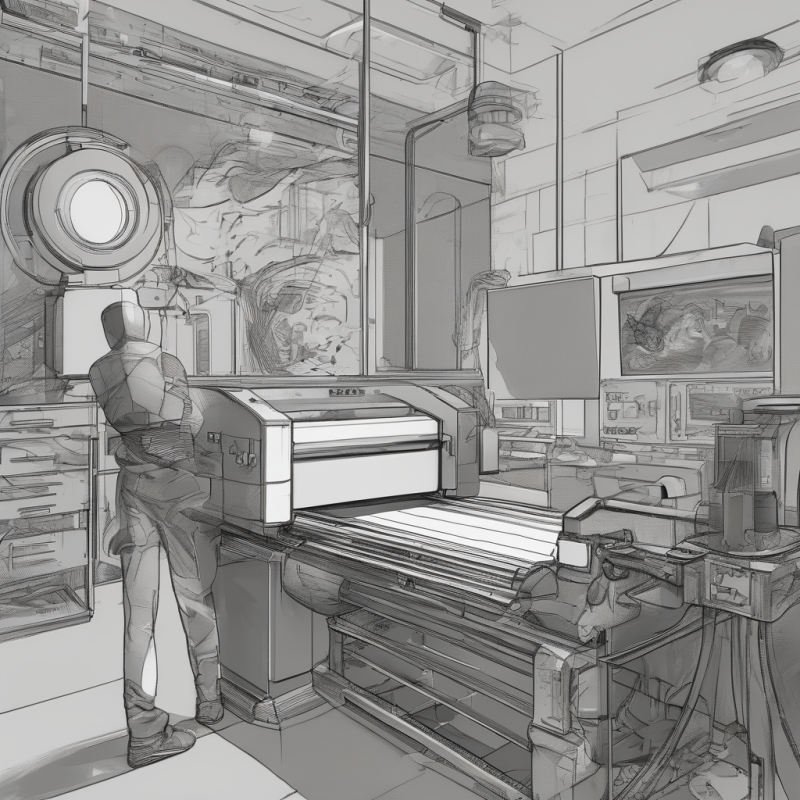

Modern technology has revolutionized various industries, and one such innovation is the industrial laser engraver. This cutting-edge tool has become indispensable for businesses seeking precise, efficient, and versatile engraving solutions. In this article, we will delve into the features, applications, and benefits of the , shedding light on why it has become a favorite among professionals. Let’s explore this fascinating tool in detail.

What is an Industrial Laser Engraver?

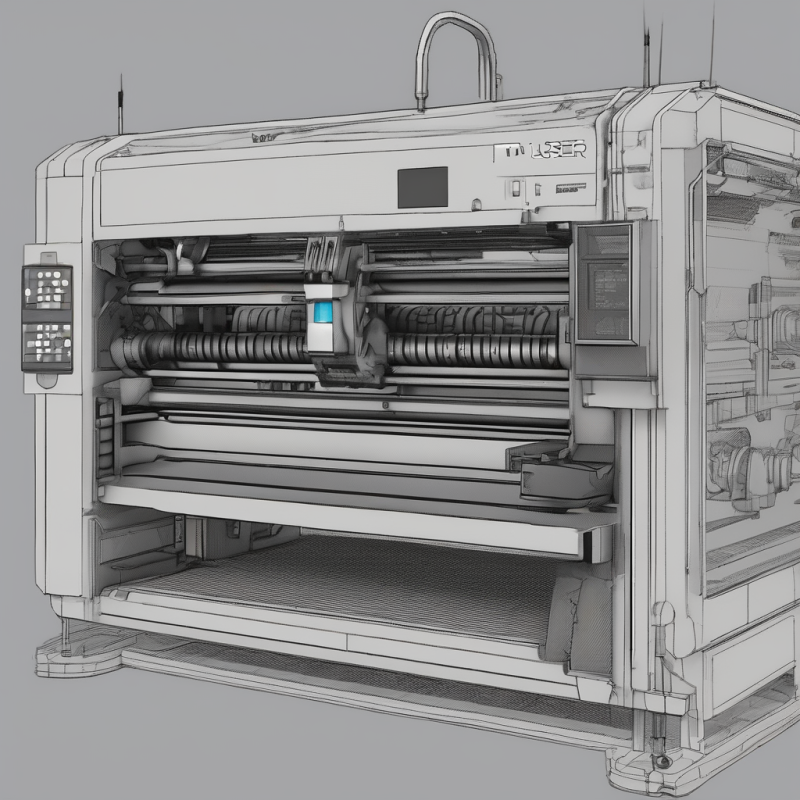

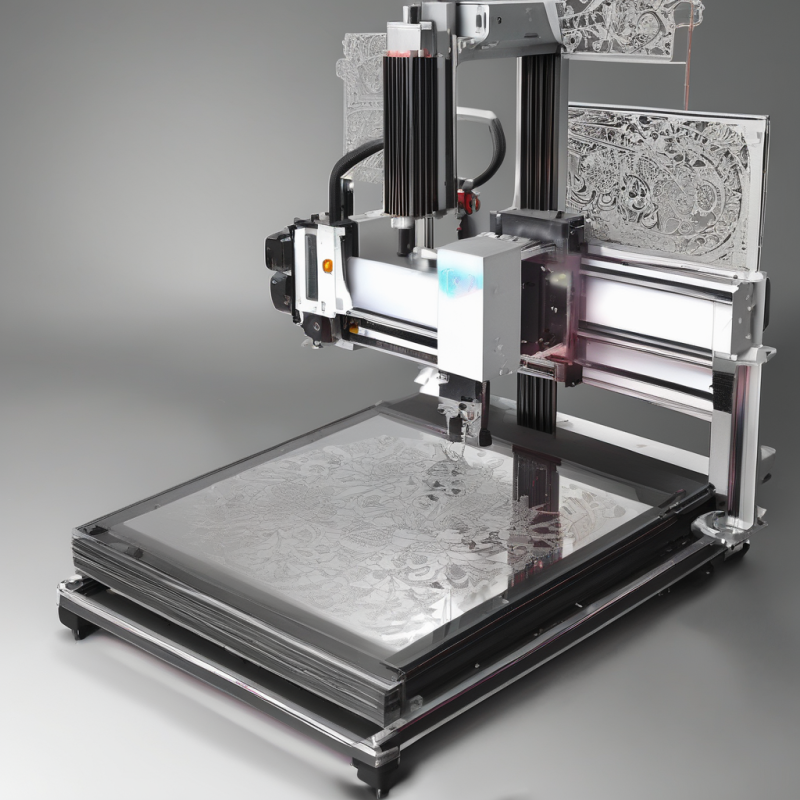

An industrial laser engraver is a machine designed to etch or carve intricate designs, text, or patterns onto various materials with exceptional precision. Unlike traditional engraving methods, which often involve mechanical tools, laser engravers use focused light beams to achieve stunning results. This process is not only faster but also more accurate, making it ideal for industries such as jewelry-making, electronics, automotive, and more.

The operates by directing a high-powered laser beam onto the material’s surface. The intense heat generated by the laser vaporizes or melts the material, creating permanent marks. This method ensures that even the most intricate designs can be reproduced with pinpoint accuracy.

Key Features of an Industrial Laser Engraver

The boasts a range of features that set it apart from conventional engraving tools. Here are some of its standout attributes:

- High Precision: The ability to focus the laser beam on an extremely small area ensures that even the most detailed designs can be engraved with clarity and precision.

- Versatility: Capable of working on a wide range of materials, including metal, wood, plastic, glass, and more, this machine offers unparalleled versatility.

- User-Friendly Interface: Modern laser engravers come equipped with intuitive software that allows users to input designs or text easily. This makes the process accessible even to those without extensive technical expertise.

- Speed and Efficiency: Compared to traditional methods, laser engraving is significantly faster, reducing production time and increasing output.

- Durable Construction: Built with high-quality components, these machines are designed to withstand the rigors of industrial use, ensuring long-lasting performance.

Applications of an Industrial Laser Engraver

The applications of an industrial laser engraver are vast and varied. Here are some common uses:

- Jewelry-Making: Engraving names, dates, or intricate designs on precious metals like gold and silver.

- Electronics: Marking circuit boards, components, and other small parts with precise details.

- Automotive Industry: Etching logos, serial numbers, or custom designs onto car parts and accessories.

- Fashion: Adding unique patterns or branding to leather goods, fabrics, and other materials.

- Packaging: Creating barcodes, QR codes, or decorative elements on product packaging for enhanced marketing appeal.

These examples highlight the machine’s adaptability across different industries, making it a valuable asset for businesses looking to enhance their production capabilities.

Maintenance and Safety Tips

While an is a robust piece of equipment, proper maintenance is essential to ensure its longevity and optimal performance. Here are some tips:

- Regular Cleaning: Dust and debris can accumulate on the machine’s surfaces and lenses. Regular cleaning with a soft cloth or compressed air will help maintain efficiency.

- Lens Care: The laser lens is a critical component. Avoid touching it directly, as oils from your skin can cause damage. Use specialized lens cleaning solutions when necessary.

- Software Updates: Keep the machine’s software up to date to benefit from the latest features and improvements.

- Safety Precautions: Always wear protective eyewear when operating the machine. Ensure the work area is well-ventilated to avoid inhaling fumes generated during engraving.

Conclusion

The industrial laser engraver represents a significant advancement in manufacturing technology, offering unparalleled precision, versatility, and efficiency. Its ability to handle a wide range of materials and applications makes it an invaluable tool for businesses across various industries. By investing in this cutting-edge equipment, companies can enhance their production capabilities, improve product quality, and stay ahead in the competitive market.

If you’re looking to upgrade your engraving processes or explore new possibilities in design and customization, consider the . Its performance is sure to impress, helping you achieve your creative and business goals with ease.

Frequently Asked Questions (FAQs)

Q1: Can an industrial laser engraver work on all types of materials?

A: While the is highly versatile, its compatibility depends on the material’s properties. It works best on materials like metal, wood, plastic, and glass but may require specific settings for certain surfaces.

Q2: Is it difficult to learn how to use an industrial laser engraver?

A: No, modern models come with user-friendly interfaces and intuitive software. With minimal training, even beginners can operate the machine effectively.

Q3: How long does a typical engraving process take?

A: The time required depends on the complexity of the design and the size of the material being engraved. Simple text or small designs may take just a few seconds, while intricate patterns could take several minutes.

Q4: Can I customize the laser settings for different materials?

A: Yes, most industrial laser engravers allow users to adjust power, speed, and focus settings to suit specific materials and design requirements. This flexibility ensures optimal results across various applications.

Q5: Is maintenance of an industrial laser engraver time-consuming?

A: Routine maintenance is straightforward and doesn’t require much time. Regular cleaning and occasional lens checks are sufficient to keep the machine running smoothly.