Exploring the Versatility of 3 in 1 3D Printer Laser Engraving & CNC Carving Machines

Introduction

In the ever-evolving landscape of modern manufacturing and creative arts, the emergence of 3 in 1 3D printer laser engraving & CNC carving machines has revolutionized the way creators and manufacturers approach their projects. These multi-functional devices are a pinnacle of technological integration, offering the capabilities of 3D printing, laser engraving, and CNC carving all in one unit. Such versatility provides users with a broad range of possibilities, increasing productivity while reducing the need for multiple standalone machines.

Understanding Laser Engraving Technology and Applications

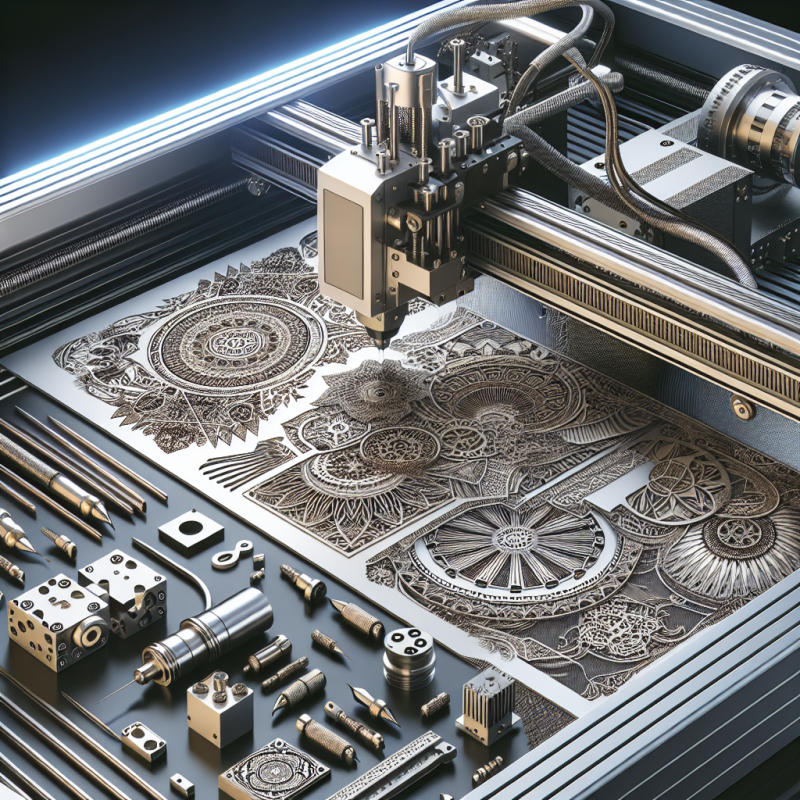

At the core of a 3 in 1 3D printer laser engraving & CNC carving machine is the laser engraving technology. Utilizing focused beams of light, these machines are capable of engraving detailed images and patterns onto various materials. This process involves removing material from the surface of an object, allowing for precise and intricate designs that are both aesthetically pleasing and functional.

Applications of laser engraving are vast, spanning from customizing products like phone cases and jewelry to industrial purposes such as marking parts for traceability. The precision and speed of laser engraving make it an invaluable tool for artists, hobbyists, and industries, making it essential to evaluate whether such a machine can enhance your business or creative projects.

Machine Specifications and Features

The specifications of a 3 in 1 3D printer laser engraving & CNC carving machine are crucial in determining its efficiency and suitability for your tasks. Typically, these machines offer a combination of powerful lasers, robust 3D printing capabilities, and precise CNC carving tools. The integration of these features into a single platform provides users with a compact and efficient tool for a variety of projects.

Key features to look for include the power of the laser source, the build volume for 3D printing, and the range of tools available for CNC carving. High-performance models, like the xTool P2S, are equipped with a CO2 laser powerful enough to cut and engrave on multiple surfaces, offering flexibility in material choices.

Material Compatibility

One of the prominent advantages of a 3 in 1 3D printer laser engraving & CNC carving machine is its compatibility with a diverse range of materials. From woods and plastics to metals and ceramics, the ability to work with different substrates allows users to experiment and create without limitations.

It’s essential to understand the capabilities of your machine concerning the materials used. The laser engraving feature may vary in effectiveness across materials, so confirming the specific engravable surfaces is advised. Similarly, CNC carving can demand different tools based on material hardness and thickness. Ensuring your machine’s compatibility with intended materials will maximize its utility and result in better finishing and precision.

Safety Considerations

Operating a 3 in 1 3D printer laser engraving & CNC carving machine requires strict adherence to safety protocols to prevent accidents. The use of laser technology inherently involves risks such as burns and eye damage. Implementing proper safety measures such as laser safety goggles, proper ventilation, and machine enclosures can mitigate these risks significantly.

Furthermore, understanding and following the manufacturer’s guidelines for maintenance and operation ensure the machine runs safely and effectively. Regular checks for wear and tear on components are also crucial for prolonging the lifespan of the machine while maintaining its performance.

Industry Best Practices

To fully leverage the capabilities of a 3 in 1 3D printer laser engraving & CNC carving machine, deploying industry best practices is key. One of the best practices is to keep your designs optimized for machine parameters. Understanding the file formats and optimizing designs can lead to more efficient processing times and reduce material wastage.

Continuous learning and staying updated with technological advancements enhance operational capabilities. Engaging with communities and forums online provides insights and tips that can improve workflow and project outcomes.

Cost-Benefit Analysis

When considering the purchase of a 3 in 1 3D printer laser engraving & CNC carving machine, conducting a cost-benefit analysis helps in understanding the financial implications and returns on investment. Although the upfront cost might seem substantial, the long-term benefits such as reduced costs of outsourcing, increased production speed, and enhanced product quality can outweigh the initial expenditure.

Moreover, the multifunctionality of these machines means you save space and money by not purchasing separate devices for 3D printing, laser engraving, and CNC carving. This consolidation benefits small businesses and startups, allowing for more efficient budget allocation while providing high-quality outputs.

Maintenance Tips

Proper maintenance of a 3 in 1 3D printer laser engraving & CNC carving machine is critical in ensuring consistent performance and longevity. Routine cleaning of components such as the laser lens and 3D printer nozzle prevents blockages and maintains efficient operation.

Regularly updating the machine’s firmware and software can also enhance its functionality and fix any bugs that might affect its performance. It’s advisable to follow a designated maintenance schedule to address wear and tear, especially for moving parts subjected to continuous operations.

Project Ideas and Tutorials

Exploring project ideas and tutorials is an excellent way to make the most of your 3 in 1 3D printer laser engraving & CNC carving machine. From creating custom home décor to intricate model sculptures, the applications are limited only by imagination. Online platforms provide numerous tutorials and templates to help users start with their projects and gradually advance to more complex designs.

Participating in workshops and seminars can also enhance skillsets, allowing users to fully realize the potential of their machines. Sharing project experiences and learning from others’ successes and challenges can provide new perspectives and ideas for future endeavors.

Conclusion

The 3 in 1 3D printer laser engraving & CNC carving machines represent a confluence of innovative technologies that can cater to a wide array of creative and manufacturing needs. Understanding their capabilities, ensuring proper usage, and maintaining these machines can significantly benefit users by enhancing productivity and broadening creative horizons. As technology continues to advance, these versatile machines will likely become even more integral to industries and individual creators worldwide.