Exploring the Versatility of PVC Laser Cutting Machines

Introduction

In the realm of modern manufacturing and design, the PVC laser cutting machine offers unparalleled precision and versatility. These machines have revolutionized how industries approach project creation, offering high-speed processing and exceptional detail orientation, particularly in cutting and engraving PVC materials. In this article, we delve into the exciting world of PVC laser cutting machines, offering insights and practical tips for prospective users.

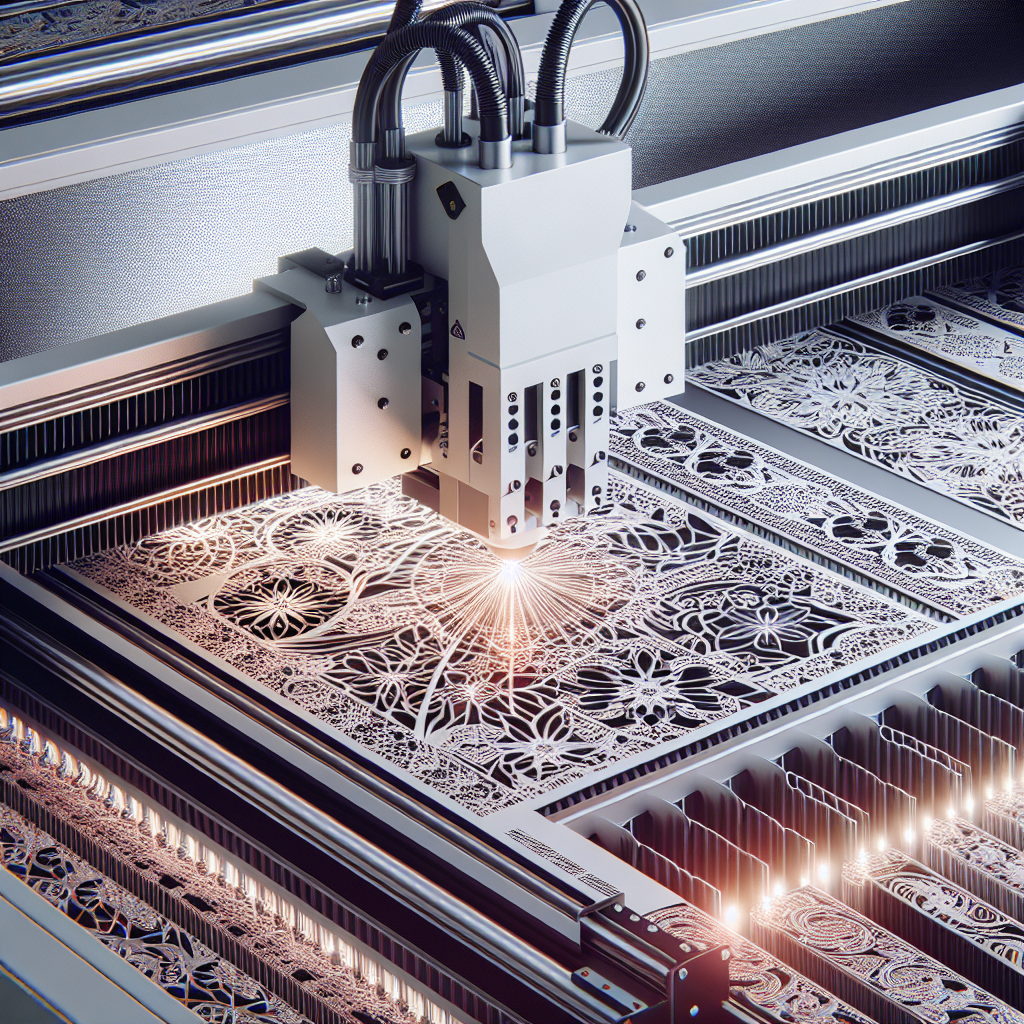

Laser Engraving Technology and Applications

Laser engraving technology is a game-changer in the field of material processing, harnessing the power of laser beams to precisely engrave or cut materials such as PVC. The applications of a PVC laser cutting machine are extensive, from crafting intricate designs on household items to enhancing industrial components. But what makes these machines so transformative?

Laser engraving technology utilizes focused light beams that vaporize the material surface, allowing for intricate designs and impeccable finishing. From personalizing a simple object to affixing logos and branding on industrial materials, the possibilities are endless. Entrepreneurs and creative artisans benefit from the machine’s ability to churn out consistent and repeatable results, vital for maintaining quality control and meeting production demands.

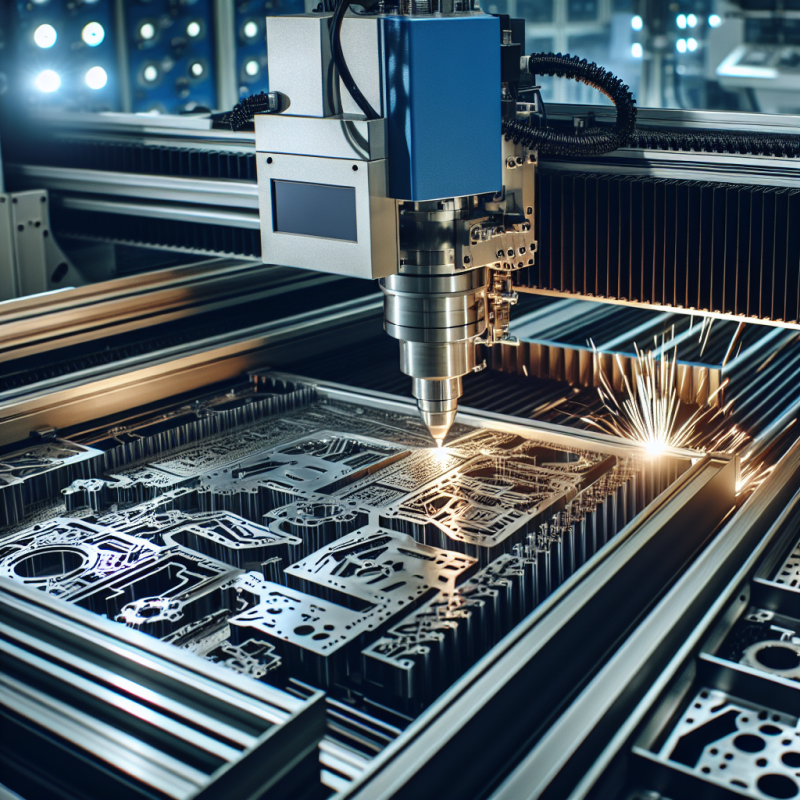

Machine Specifications and Features

At the heart of the PVC laser cutting machine lies its specifications and features, which dictate its performance and suitability for specific tasks. These machines typically offer adjustable power settings, high-resolution capabilities, and compatibility with various design software. But what should you look for when assessing a laser cutting machine?

- Power Output: Determines the machine’s ability to cut or engrave materials of varying thicknesses.

- Resolution: Higher resolution translates to more detailed engraving and cutting capability.

- Speed: Allows for faster processing times and increased productivity.

- Software Compatibility: Ensures the machine can read and process complex design files effortlessly.

- Maintenance Requirements: Consider easy-to-maintain machines that do not require frequent servicing.

Material Compatibility

Choosing the right laser cutter also depends heavily on material compatibility, a crucial factor in ensuring optimal efficiency and output quality. How do you ensure your PVC laser cutting machine matches the required material standards?

Laser machines are often designed to work with a variety of materials; however, PVC stands out due to its flexibility and robustness once processed. Ensure that the machine’s settings can be efficiently adjusted for the material’s thickness and density, promoting clean cuts and well-defined engravings. Additionally, assessing if the machine uses a non-contact method will reduce the risk of material warping or damage.

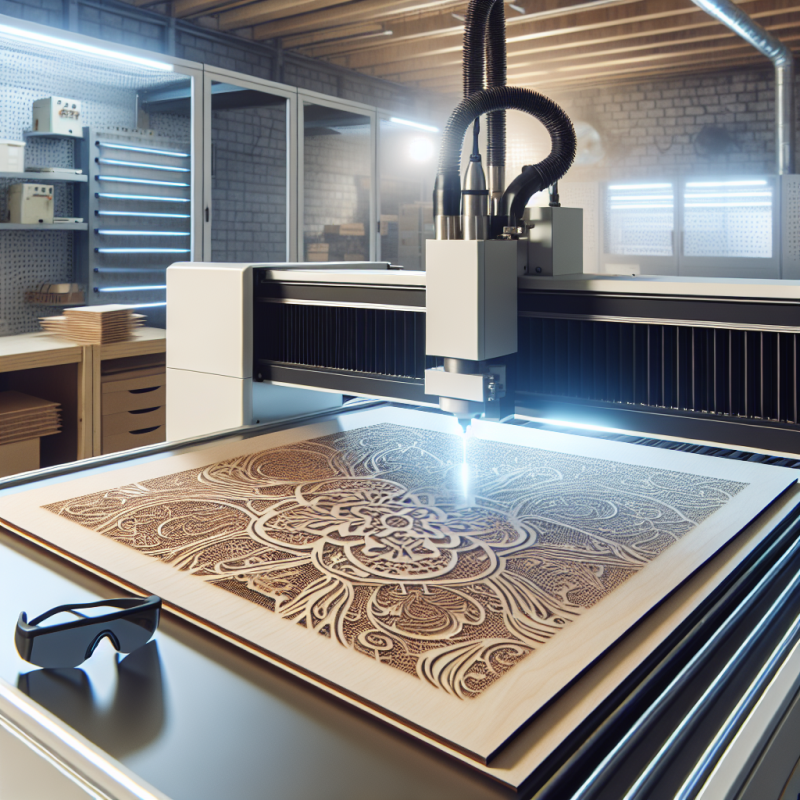

Safety Considerations

Like any technological tool, safety remains paramount when operating a PVC laser cutting machine. What safety protocols should users adhere to for safe operation?

- Proper Ventilation: Ensure adequate ventilation to disperse potentially harmful fumes released when cutting PVC.

- Eye Protection: Lasers can damage eyesight, so wearing protective eyewear and employing shields is necessary.

- Fire Safety: Keep a fire extinguisher nearby as high-intensity jobs can pose fire risks.

- Regular Maintenance: Conduct regular checks and servicing to ensure the machine operates safely and efficiently.

Industry Best Practices

To maximize the efficiency and lifespan of a PVC laser cutting machine, adhering to industry best practices is vital. What strategies effectively enhance machine performance and product quality?

- Calibration: Regular calibration ensures precision in cuts and engravings, supporting consistency in output.

- Cleanliness: Keeping the machine clean of debris and residue promotes better functionality.

- Training: Equip operators with adequate training to manage the machine effectively and troubleshoot minor issues.

- Design Optimization: Utilize software to optimize designs before engraving to minimize waste and improve quality.

Cost-Benefit Analysis

Investing in a PVC laser cutting machine represents a considerable financial commitment, so conducting a cost-benefit analysis is critical. Why should businesses prioritize this analysis?

Evidently, understanding the initial costs, potential returns, and hidden long-term savings can dictate investment success. While the upfront acquisition costs may be steep, consider the following benefits:

- Increased Productivity: Faster turn-around times allow businesses to handle larger volumes, boosting revenue.

- Enhanced Quality: Consistent, high-quality products often increase customer satisfaction and loyalty.

- Cost Efficiency: Precision cutting reduces waste and material costs over time.

- Innovation: A laser machine encourages creativity, opening doors to new services and market segments.

Maintenance Tips

Just as crucial as the machine’s purchase is its maintenance. How do users keep their PVC laser cutting machine running smoothly?

- Regular Inspection: Identifying wear and tear early prevents serious breakdowns.

- Software Updates: Ensure the operating software is up to date for improved functionality.

- Lens Cleaning: Clean lenses ensure precise and accurate beam quality for better results.

- Lubrication: Keep moving parts well-lubricated to reduce friction and prolong device life.

Project Ideas and Tutorials

Exploration of project ideas can prove highly beneficial for users eager to tap the full potential of their PVC laser cutting machine. What innovative projects can you undertake?

- Create custom signage perfect for businesses, events, or personal space enhancements.

- Design intricate patterns for decorative items, enhancing aesthetics in interior design.

- Develop bespoke gifts, such as personalized plaques or coasters, adding sentimental value and uniqueness.

- Engage in source reduction projects by crafting parts or components with precision, minimizing material waste.

Finally, to support your laser cutting journey, numerous online resources and tutorials are available that can offer guidance and inspiration. Working through these projects and tutorials can familiarize you with various machine functions, enabling you to master your skills and come up with groundbreaking creations.

In conclusion, the advent of the PVC laser cutting machine marks a significant innovation milestone, simplifying complex tasks and broadening creative horizons. Whether you’re crafting, business-focused, or exploring cutting-edge designs, this machine endows you with the power to create with accuracy and finesse. But as with any tool, understanding its capabilities and limitations, alongside maintaining safety and efficiency, remains imperative for optimal use. Embrace this sophisticated technology and unleash your potential today!