Exploring the Wonders of the Metal Laser Cutting Machine

Introduction

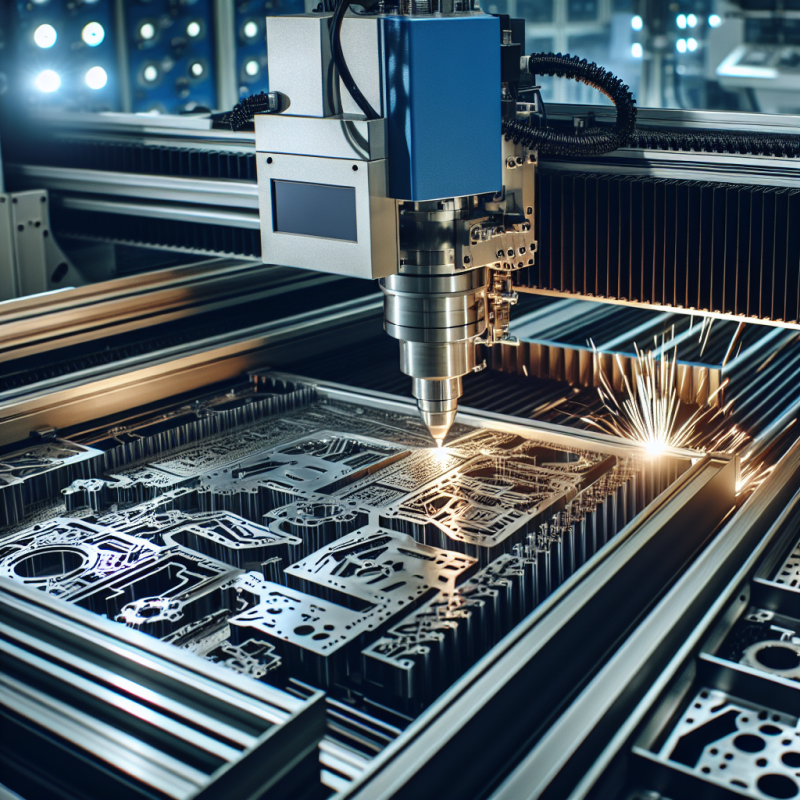

In today’s fast-paced and technologically advanced world, the metal laser cutting machine has revolutionized the way industries approach manufacturing and design tasks. This innovative technology offers precision, efficiency, and versatility that traditional cutting methods simply cannot match. Whether you are a seasoned professional or a beginner exploring the possibilities of laser cutting, understanding the capabilities and applications of these machines is essential for maximizing their benefits.

Laser Engraving Technology and Applications

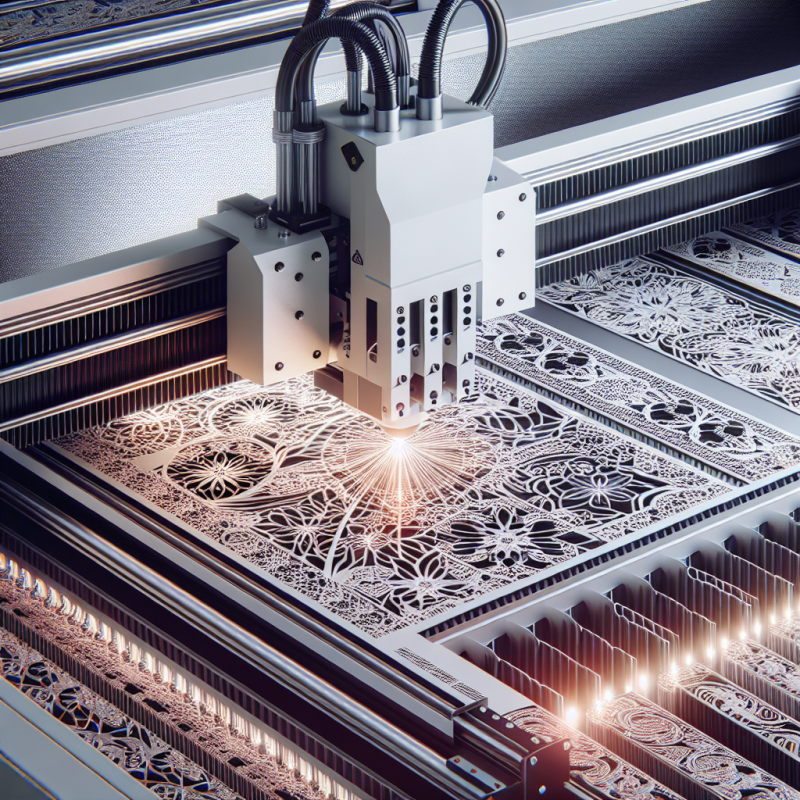

The emergence of laser engraving machines has opened up a new realm of possibilities for various industries. At the heart of these machines lies the powerful technology that uses a laser beam to cut or engrave materials. The precision of the laser offers unparalleled accuracy, allowing intricate designs that were once impossible to achieve using conventional methods.

This technology finds applications in numerous fields, from manufacturing and jewelry design to signage and art. One of the major advantages of laser engraving is its ability to produce remarkably detailed and high-quality engravings on metals, which makes it indispensable in creating industrial components and personalized goods.

Machine Specifications and Features

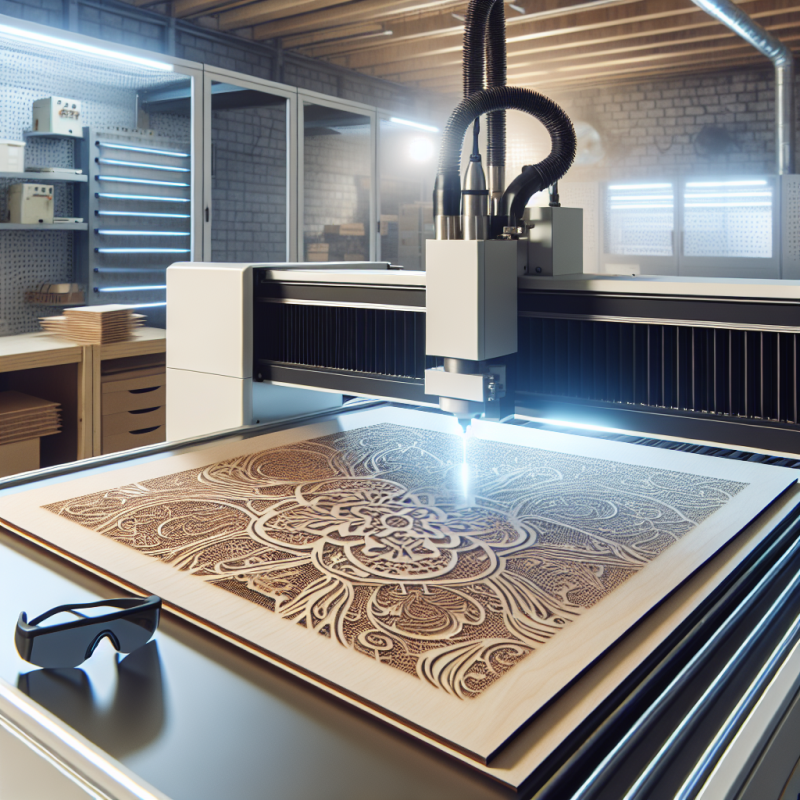

When considering the purchase of a metal laser cutting machine, it’s important to understand its specifications and features to ensure it meets your specific needs. These machines come in a range of sizes and power levels, each designed for different materials and project types.

- Power capacity: Ranges from 30W to over 1000W, determining the thickness of metal that can be cut.

- Bed size: Varies based on the machine, impacting the maximum size of materials that can be processed.

- Speed and precision: Advanced machines can execute faster cuts with higher precision.

- Software compatibility: Many machines come with proprietary software, but compatibility with common design software is an advantage.

- User interface: Touchscreens and intuitive interfaces make it easier for operators to control the machine.

Material Compatibility

Metal laser cutting machines are lauded for their versatility in working with a variety of materials. This flexibility is one reason why they are preferred in different sectors. Typically, these machines can cut and engrave materials such as stainless steel, aluminum, copper, and brass. The choice of material will largely influence the laser power required and the speed settings of the machine.

For those specifically looking to work with metals, it’s crucial to verify the material compatibility of a metal laser cutting machine model before making a purchase. Certain alloys may require special settings or additional accessories to process safely and effectively.

Safety Considerations

Safety is paramount when operating a laser cutting machine. The powerful laser beam can pose risks if not handled properly. Here are some essential safety considerations:

- Use appropriate safety goggles to protect your eyes from laser exposure.

- Ensure the workspace is well-ventilated to avoid inhaling fumes generated during laser cutting.

- Follow proper lockout/tagout protocols when servicing or maintaining the machine.

- Regularly inspect the machine for any signs of wear or damage that could compromise safety.

- Familiarize yourself with the machine’s emergency shutdown procedures.

Implementing these safety measures will help minimize risks and ensure a safe operation environment.

Industry Best Practices

To fully leverage the capabilities of a metal laser cutting machine, adhering to industry best practices is essential. These include:

- Regular maintenance and cleaning to keep the machine in optimal working condition.

- Proper calibration to ensure accuracy and precision in every cut or engraving.

- Using recommended settings based on the material and desired output.

- Training operators adequately so they are familiar with the machine’s functions and safety measures.

Following these practices can significantly enhance productivity and prolong the life of the machine.

Cost-Benefit Analysis

Investing in a metal laser cutting machine can be a substantial financial commitment. However, the long-term benefits often outweigh the initial costs, making it a worthwhile investment for businesses and individual users alike. The speed and precision of laser cutting reduce waste and save time compared to manual methods, leading to increased efficiency and profitability.

Additionally, the versatility of laser machines eliminates the need for multiple tools and reduces labor costs. When performing a cost-benefit analysis, consider the potential for expanding your range of services and improving product quality and turnaround times.

Maintenance Tips

To keep your metal laser cutting machine running smoothly and efficiently, regular maintenance is crucial. Here are some **maintenance tips**:

- Regularly clean the lenses and mirrors to ensure the laser beam is not obstructed.

- Lubricate moving parts to prevent wear and tear.

- Check all electrical connections for signs of damage or corrosion.

- Replace filters and ventilation systems as needed to maintain proper airflow.

- Review and update software regularly to benefit from new features and improvements.

By following these tips, you can help extend the lifespan of your machine and maintain high levels of performance.

Project Ideas and Tutorials

Unlocking the true potential of a metal laser cutting machine involves experimenting with different project ideas and tutorials:

- Create custom jewelry pieces with intricate designs.

- Design bespoke metal signs for businesses or personal use.

- Develop decorative art pieces and sculptures.

- Craft personalized gifts such as engraved keychains or plaques.

- Engage in prototyping for product development and testing.

Exploring a variety of projects can help broaden your skills and inspire innovative applications for laser technology.

Conclusion

The metal laser cutting machine represents a blend of technology and creativity, offering endless possibilities for industries, businesses, and hobbyists. By understanding its features, applications, and best practices, users can fully exploit the potential of this remarkable tool. Whether you are aiming to improve production efficiency or explore artistic avenues, the investment in a laser cutting machine paves the way to success.