Exploring the World of Steel Laser Engraving Machines

Introduction

In today’s fast-paced manufacturing and design industries, a steel laser engraving machine represents the pinnacle of precision and efficiency. These machines are reshaping how we approach everything from intricate designs to large-scale industrial applications. In this article, we will dive deep into the technology behind steel laser engraving, discuss its diverse applications, and explore the many advantages it offers to modern users.

Laser Engraving Technology and Applications

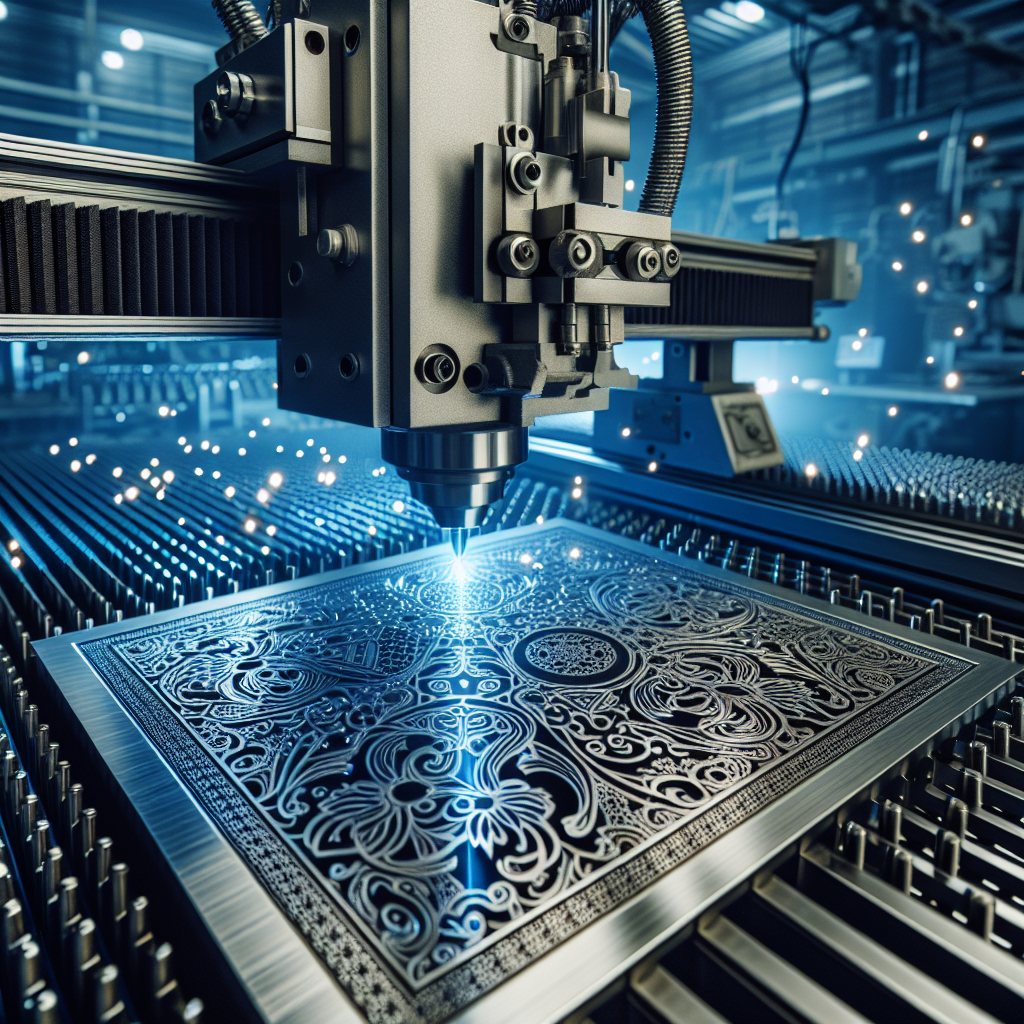

The art and science of laser engraving have been evolving rapidly. At its core, a steel laser engraving machine uses highly focused laser beams to mark, etch, or engrave designs onto metal surfaces. This technology allows for incredible detail, capturing even the most intricate patterns with precision that other methods can hardly match.

Applications of steel laser engraving machines span a wide range of industries. From creating custom jewelry and personalized trophies to marking industrial components and electronic devices, the possibilities are nearly endless. The unique advantage of these machines is their ability to work on a variety of materials, ensuring high-quality results across the board.

Machine Specifications and Features

When considering a steel laser engraving machine, it is essential to know about its specifications and features. The size of the worktable, laser power rating, and software compatibility are crucial factors that ultimately determine the output quality and efficiency of the process. Modern engravers often include features such as automatic focus adjustment, rotary attachments for round objects, and user-friendly interfaces to ensure a smooth experience.

Why are these features important? They empower users to take on complex projects with ease, provide consistent quality in production, and reduce setup times significantly. A strong laser source ensures that even the hardest metals can be engraved with minimal tool wear and maintenance.

Material Compatibility

Steel laser engraving machines are not limited to just one type of material. While they excel at engraving steel for industrial purposes, versatility is one of their greatest strengths. These machines can handle aluminum, copper, brass, and even non-metal materials such as plastics and wood.

But what does material compatibility mean for users? It provides greater flexibility in the types of projects possible and opens up creative avenues that might otherwise remain unexplored. Understanding how your machine interacts with different materials can also improve your approach to design and increase the longevity of the engraving tool.

Safety Considerations

Operating any heavy machinery comes with safety considerations that must not be overlooked. Steel laser engravers use powerful lasers which, if not handled properly, can pose risks such as skin exposure or material fires. Manufacturers provide detailed safety guidelines, which usually include wearing appropriate gear such as safety goggles and ensuring adequate ventilation during the engraving process.

Why is safety so critical? Beyond preventing injury, observing safety protocols ensures the longevity of your machinery and maintains optimal operational standards. A well-maintained machine operates more efficiently, providing consistent high-quality results without compromising user safety.

Industry Best Practices

Success with a steel laser engraving machine relies on adhering to industry best practices. This includes regular maintenance, understanding laser settings for various materials, and utilizing the full range of machine capabilities. Continuous learning and adapting to new technologies and methods keep operators at the forefront of the industry.

One frequently asked question is how to optimize engraving speed without sacrificing quality. The answer often lies in trial and experience—understanding the balance between laser strength and movement speed for different materials. Workshops and user forums can also be valuable resources for staying up-to-date with the latest techniques and tech improvements.

Cost-Benefit Analysis

Investing in a steel laser engraving machine requires thorough consideration of the initial cost versus long-term benefits. While these machines might come with a higher upfront investment, the precision and efficiency they offer can improve productivity and reduce waste over time, leading to substantial savings.

What are some of the other cost benefits associated with steel laser engravers? They offer reduced tool wear, which minimizes maintenance costs, and their versatility means you can take on a wider range of projects without needing additional equipment. Additionally, rapid prototyping capabilities allow for quick turnaround times that can provide competitive advantages.

Maintenance Tips

Regular maintenance is crucial to ensure that your steel laser engraving machine operates at peak performance. Simple practices such as cleaning the laser optics regularly, checking alignment, and ensuring the work environment is dust-free can go a long way in preventing issues.

Routine software updates also play a critical role, as they can provide new features, improve security, and enhance machine performance. Bearing these points in mind can help users achieve prolonged machine lifespan and consistent quality results.

Project Ideas and Tutorials

Innovative project ideas can help users fully realize the potential of their steel laser engraving machines. Whether you are interested in creating personalized gifts, automotive parts, or architectural models, the Internet is full of tutorials and ideas that can inspire your next project.

What are some easy beginner projects? Start with simple etch designs on small metal plaques or create custom tags and keychains. As you grow more comfortable with the machine’s capabilities, you can move on to complex engraving patterns that require both precision and skill.

Moreover, community forums and industry conferences often provide a platform to share knowledge, troubleshoot issues, and showcase your creations. Engaging with these communities not only benefits individual creativity but may also enrich the collective understanding of laser engraving technologies.

Conclusion

The market for steel laser engraving machines continues to grow as new innovations pave the way for more efficient and precision-driven projects across many industries. By understanding the technology, applications, and practices associated with these machines, users can not only improve their craft but also find new opportunities for business growth and personal creativity.

As we advance into an era dominated by technology and customization, the role of the steel laser engraving machine as a vital tool in both personal and professional capacities cannot be overstated. With the right approach, these machines offer a gateway into a world where imagination truly meets precision.