Fibre Laser Engraver: Revolutionizing Precision in Engraving

Introduction

In the evolving landscape of manufacturing and artistic production, the fibre laser engraver has emerged as a pivotal technology. Combining efficiency and precision, this technology has introduced a new era of customization, allowing users to engage with materials like never before. Whether you are looking to enhance your personal crafting abilities or streamline an industrial process, the fibre laser engraver offers unparalleled potential.

Laser Engraving Technology and Applications

At its core, laser engraving technology functions by emitting a focused beam of light that intricately marks the surface of various materials. This precise method enables incredible detail and accuracy, making it suitable for a diverse range of applications. From producing durable barcodes and serial numbers on metal surfaces to crafting intricate designs on leather goods, the fibre laser engraver stands out for its versatility.

What are some of the most common applications for fibre laser engravers? These machines are extensively used in industries such as electronics, automotive, and jewelry where precision is crucial. Furthermore, artists and small business owners leverage the technology for creative projects ranging from personalized gifts to bespoke home decor items.

Machine Specifications and Features

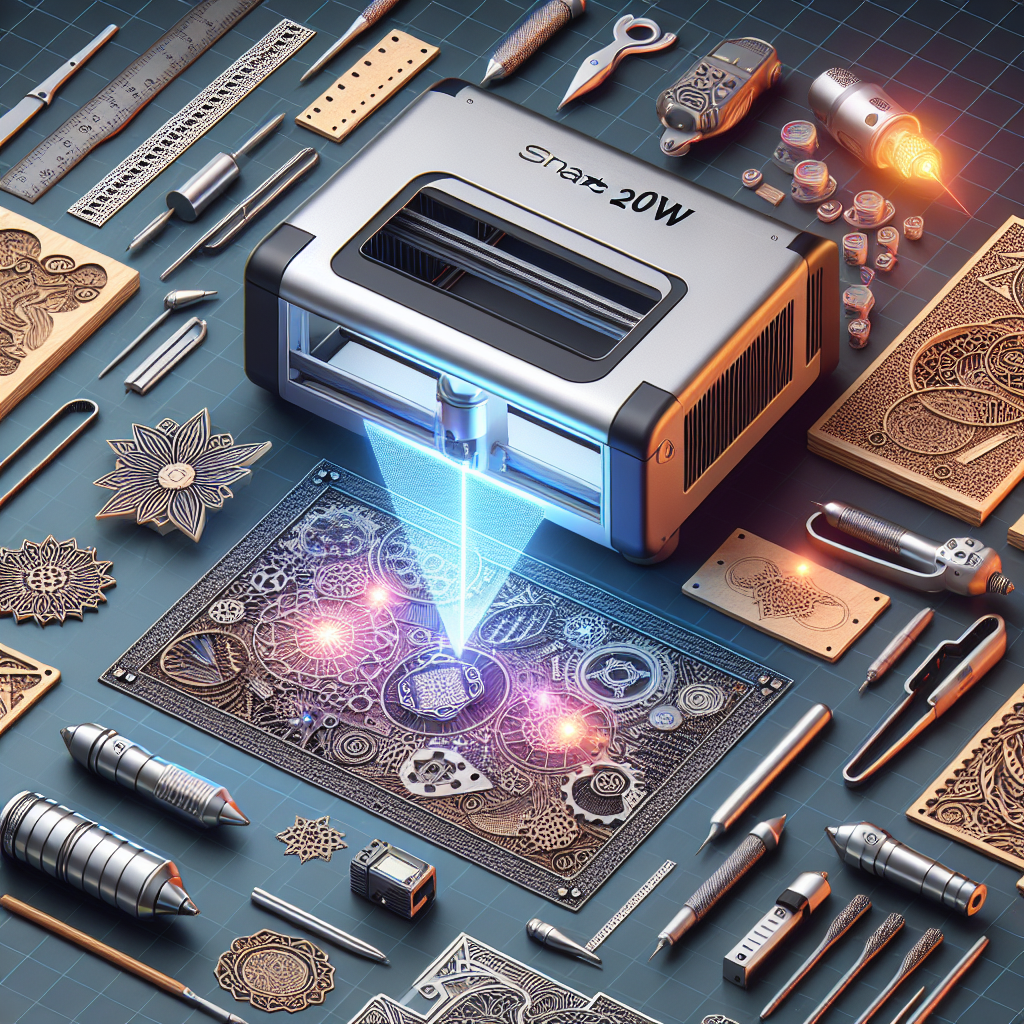

Understanding the specifications is intrinsic to utilizing a fibre laser engraver to its fullest potential. The Laserpecker LP5, a smart 20W fiber diode laser engraver, showcases leading-edge engineering with its robust build and innovative features. Its compact design and user-friendly interface allow both amateurs and professionals to handle complex projects with ease.

Key features include adjustable settings for engraving speed and power, ensuring optimal results across different materials. The machine’s connectivity options further enhance its usability, permitting seamless integration with various design software platforms.

Material Compatibility

A critical component in the successful use of a fibre laser engraver is understanding material compatibility. While traditional laser engravers are often limited to soft materials, fibre laser engravers boast the capacity to mark a wide array of substrates. These include metals such as steel, aluminum, and brass, alongside non-metallic materials like wood, acrylic, and certain types of plastics.

Are there materials that cannot be engraved using a fibre laser engraver? Yes, materials with reflective surfaces like glass and some ceramics may require specific adjustments or are unsuitable for standard fibre laser engravers without additional features or coatings to prevent reflections.

Safety Considerations

Operating a fibre laser engraver necessitates adherence to safety standards to protect users from potential hazards. Though the technology is generally safe when used correctly, there are inherent risks associated with operating high-powered lasers.

Key safety precautions include using protective eyewear to shield against laser light exposure, maintaining a well-ventilated area to disperse any fumes generated from materials, and following all manufacturer guidelines meticulously. Regular maintenance checks are also vital to ensure the engraver is in optimal condition.

Industry Best Practices

Adopting best practices is essential to maximizing the efficiency and lifespan of a fibre laser engraver. One of the foremost recommendations is to conduct preliminary tests on sample materials before engaging in full-scale production. This procedure helps ascertain the correct settings for depth, speed, and power depending on the material being used.

Should you clean the machine regularly? Absolutely. Keeping the lens and mirrors free from dust and material residue ensures clear laser paths, reducing the risk of damage or diminished performance.

Cost-Benefit Analysis

Investing in a fibre laser engraver can be significant, prompting the need for a thorough cost-benefit analysis. While the initial purchase price may seem high, the long-term savings and productivity gains often outweigh this expenditure.

What benefits justify the cost? The engraver’s durability and low maintenance requirements reduce ongoing expenses. Additionally, its versatility in handling various projects means users can diversify offerings, enhancing their business income potential. The high speed and precision of a fibre laser engraver translate to a faster production rate, ensuring a quicker return on investment.

Maintenance Tips

To keep your fibre laser engraver in peak condition, adhere to a consistent maintenance schedule. Regular cleaning of components such as the laser head and mirrors is imperative. Avoid using harsh chemicals for cleaning, as they can damage sensitive parts. Instead, opt for specialized cleaning solutions recommended by the manufacturer.

Is it important to conduct routine software updates? Yes, keeping the engraver’s firmware up-to-date ensures improved functionality and access to new features. Moreover, periodically aligning the laser beam can prevent operational issues and extend the machine’s lifespan.

Project Ideas and Tutorials

Looking to start a project but unsure where to begin? A fibre laser engraver opens a plethora of opportunities for both creative and functional creations.

- Customize metal business cards to make a distinct impression.

- Create personalized jewelry with intricate patterns and text.

- Engrave branding and logos on metal and acrylic promotional products.

- Design intricate architectural models using various materials for educational purposes.

- Experiment with layered art pieces using wood and accentuate them with metallic details.

Does exploring project ideas enhance one’s skills? Absolutely. Experimenting with different materials and designs not only builds proficiency with the machine but also expands creative boundaries, leading to innovative outcomes.

In conclusion, the fibre laser engraver stands as a versatile and powerful tool for a multitude of applications. With the ability to handle various materials and produce intricate designs, it offers numerous opportunities for innovation and efficiency across multiple domains. By following industry best practices and maintaining the machine diligently, users can ensure their investment in this cutting-edge technology yields rewarding results.