Foam Laser Cutter: Unleashing Creativity and Precision

Introduction

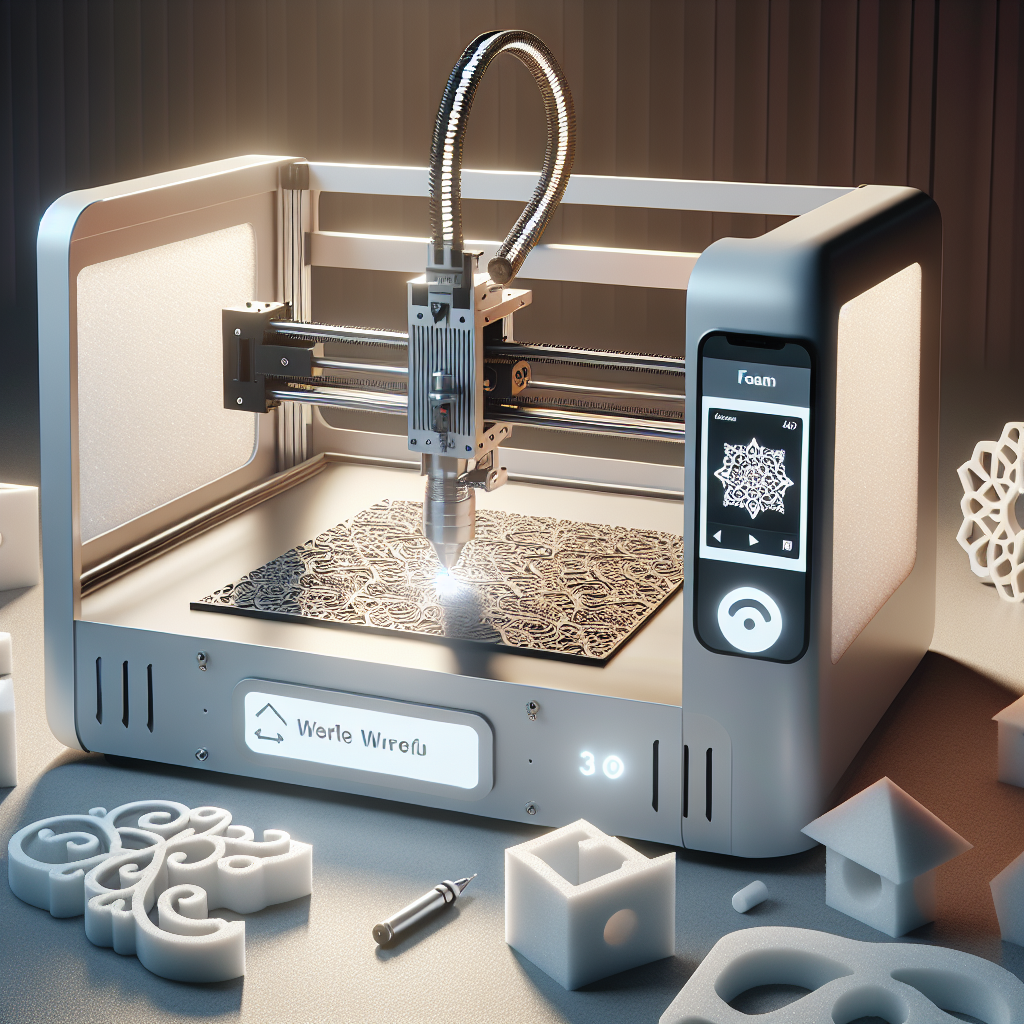

In the realm of modern fabrication and creative projects, the foam laser cutter stands out as a revolutionary tool. This device combines state-of-the-art laser technology with user-focused design, enabling users of all skill levels to undertake intricate projects effortlessly. This article delves into the world of foam laser cutting, exploring its applications, features, safety measures, and more.

Laser Engraving Technology and Applications

The advent of laser engraving technology has transformed the way we approach design and manufacturing. Initially developed for industrial applications, laser engraving is now accessible to hobbyists and small businesses, thanks to user-friendly devices like the foam laser cutter. But what exactly can you accomplish with such a machine?

Primarily, laser engravers use a concentrated beam of light to vaporize materials precisely, etching detailed designs onto a wide variety of surfaces. This level of precision makes them ideal for projects ranging from personalized gifts to signage and prototypes. The versatility of a foam laser cutter is unmatched, suitable for engraving logos, intricate patterns, and even text with stunning accuracy.

Machine Specifications and Features

Understanding the specifications and features of your foam laser cutter is essential for optimizing its use. A typical entry-level model, such as the LaserPecker LP1 Pro, boasts a compact design without compromising power. It is engineered to offer precision and ease of use, regardless of the project scale.

Key features often include an adjustable laser head, allowing for varied intensity settings depending on the material. Advanced models might also offer wireless connectivity through apps, enabling seamless operation from smartphones or tablets. With high-speed engraving capability, users can expect to achieve high-quality results efficiently, making it suitable for both personal and commercial applications.

Material Compatibility

One of the most frequently asked questions about the foam laser cutter is its compatibility with different materials. The answer? It varies depending on the laser’s power and wavelength. However, most foam laser cutters are designed to work with a broad spectrum of materials.

- Foam: Ideal for detailed and precise cuts without tears or burn marks.

- Wood: Capable of creating smooth cuts and intricate designs on various wood types.

- Plastic: Excellent for customized parts and components.

- Leather: Perfect for fashion accessories and personalized items.

- Fabric: Allows for the creation of custom patterns and designs.

While some metals and glass may pose challenges due to their reflective properties, innovators continuously push the boundaries of what these machines can achieve.

Safety Considerations

With the power of precision lasers comes the responsibility of safe use. Users must adhere to specific safety practices to prevent accidents. First and foremost, operators should always wear protective eyewear to shield their eyes from any stray laser reflections. Furthermore, adequate ventilation is necessary to disperse any harmful fumes or particles released during the engraving process.

Regular machine maintenance is crucial. This includes cleaning the laser lenses and ensuring all moving parts are free from debris, which could affect performance and safety. Modern machines often come equipped with auto-shutoff features if they detect anomalies, serving as an additional safeguard for operators.

Industry Best Practices

Taking full advantage of the capabilities of a foam laser cutter means adhering to industry best practices. Precise calibration of the laser strength for each specific material ensures the highest quality outcome while minimizing wear on the machine. Moreover, consistent maintenance checks can prevent unexpected downtimes and extend the machine’s lifespan.

Engraving professionals recommend conducting test runs on scrap materials to dial in the perfect settings before embarking on a major project. This practice not only saves time but also helps to avoid costly mistakes and material waste.

Cost-Benefit Analysis

Investing in a foam laser cutter involves an upfront cost, but the benefits often outweigh the initial expenditure. Users can expect increased productivity as manual cutting and crafting are replaced by automated precision. For businesses, this often translates to higher profit margins and the ability to offer diversified services.

The durability and long-term value of these machines further justify the investment. With proper care and usage, they can provide years of service, making them a strategic asset for both small-scale artisans and large manufacturing firms alike.

Maintenance Tips

For users wanting to maximize their foam laser cutter’s performance and longevity, regular maintenance is crucial. Keeping the machine clean and free of residue, particularly on the optical lenses, ensures consistent engraving quality.

Lubricating moving parts and checking electrical connections for wear can prevent operational issues. Calibration checks should be done periodically to maintain accuracy across projects. Moreover, software updates provided by manufacturers often improve functionality; thus, staying updated is beneficial.

Project Ideas and Tutorials

The possibilities with a foam laser cutter are nearly limitless. For beginners, starting with simple projects such as engraved coasters or personalized keychains could provide valuable practice. As proficiency grows, more challenging designs – like multi-layered artwork or detailed model prototypes – can be tackled.

Tutorials and project guides abound online, offering step-by-step instructions and inspiration. Community forums and social media groups also provide a platform for users to share their creations, tips, and experiences.

Conclusion

As the world of digital fabrication expands, the foam laser cutter emerges as a pivotal tool for artists, craftsmen, and businesses alike. Its blend of advanced technology and user-friendly design empowers creators to push the boundaries of what’s possible in engraving. By understanding its features, adhering to safety protocols, and engaging with a vibrant community of users, anyone can harness this tool to unlock endless creative potential.